Tag: Respect for People

Nick Katko and Mike De Luca Talk About Practicing Lean Accounting

Scroll down for how to subscribe, transcript, and more

My guests for Episode #428 of the Lean Blog Interviews Podcast are Nick Katko and Mike De Luca....

Does Staying OSHA Compliant Really Keep a Company Lean?

Today's post is written by my friends at Creative Safety Supply. They have been a long-time sponsor of the Lean Blog and I appreciate...

Episode #20 of “Lean Whiskey”: Live from the Colorado Lean Network...

In Episode 20, Mark Graban and Jamie Flinchbaugh join the Colorado Lean Summit live and host a virtual happy hour while discussing the first...

CEO Akio Toyoda’s Perspectives on the Toyota Production System

I was really happy to see this publication by Toyota, from Japan but in English:

"Akio Toyoda's View on Toyota Production System"

There are seven sections:

1....

Respect for People as a Competitive Advantage in Major League Baseball

"Respect for people" is, of course, a core tenet of Lean and the Toyota Production System. It's an important idea in the workplace and...

Reflections on Respect and Countermeasures — In Workplaces and Society

The past few months have been an anxious and contemplative time. I've been worried about the coronavirus / Covid-19 and the possible impact on...

See? Lean is About Flexibility, Not Low Inventory

It's great to see examples of manufacturing companies being flexible and adaptive in these challenging times. Lean methods are often providing a huge boost...

Making People and Making Things – in Japan or Mr. Rogers’...

Monday was the first day of my fifth Lean study trip to Japan. Yesterday, I had the opportunity to once again visit a Toyota...

An Amazing Virtual Plant Tour (and More) at the Toyota North...

Last month, I had an opportunity to visit the Toyota North American Headquarters that's now near me in Plano, Texas. Thanks to the MIT...

What This Hospital President Said About Lean, Respecting Staff, and Just...

This article made me smile the other day -- especially the comments about Lean, front-line staff, and systems:

Q & A with Art Gianelli, president...

When “Red Beads” Lead to What Looks Like Workplace Discrimination

Quite often, I used the famed "Red Bead Game" (a.k.a. the "Red Bead Experiment") that was made famous by W. Edwards Deming.

Here are my...

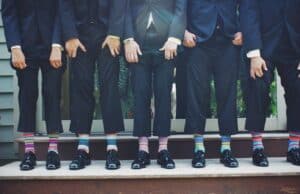

So Who Else Forgot to Pack Socks?

Last week, I had the chance to teach and facilitate a Lean education session for a group of health system executives and physician leaders...