Tag: Quality

Dr. Gary Kaplan and Virginia Mason Medical Center’s “War on Waste”

A few of you sent me this article from Modern Healthcare (thanks!):

Virginia Mason Health CEO Dr. Gary Kaplan wages a war on waste

As you...

On Boeing, GM, and Hospitals… and Epic Battles Between Reality and...

Yesterday's blog post was about a situation (with my podcast hosting service) that triggered memories of my time at General Motors in 1995. Today's...

On Podcast Server Downtime, Scars from General Motors, and Taking Ownership...

Ever since I started podcasting in 2006, I've been using a company called "Hipcast" to be the "hosting" company for the podcast audio files...

Journalists — Please Stop Using “Assembly Line” as a Lazy Synonym...

Back in 2006, I wrote my first blog post about the unfortunate use of "assembly line" to mean "bad quality." The context there was...

Adventures in Self Publishing: Defects & Escapes

When I started my career in the auto industry, I learned that a "not defect" is a product that doesn't meet specifications in some...

Friday Night at the ER: Fun Learning Through a Tabletop Simulation

Actually being a patient in the emergency department is a learning experience, to say the least. I've done that twice in the past twelve months (two cases of really bad stomach flu with high fever). I don't recommend this if you can avoid it.

What I do recommend is an interactive learning experience called "Friday Night at the ER."

More about that in today's post...

Podcast #310 – Steve Shortell, The Impact of #Lean on Healthcare...

Joining me again for Episode 310 is Stephen M. Shortell Ph.D., MPH, MBA. He is Blue Cross of California Distinguished Professorship, HPM and is a Professor of Organizational Behavior at the University of California, Berkeley School of Public Health.

He was previously a guest on Episode 267 talking about the establishment of the Center for Lean Engagement and Research (CLEAR) at the University of California, Berkeley, where he is the director.

In this episode, we talk about some initial research that they released in a paper that was published in The Joint Commision Journal on Quality and Patient Safety:

"Use of Lean and Related Transformational Performance Improvement Systems in Hospitals in the United States: Results From a National Survey"

Lean Healthcare Featured in “The Economist”

It's great to see Lean healthcare featured in one of the world's leading news and business publications. The Economist recently published this article:

"Hospitals are learning from industry how to cut medical errors"

Quality Improvement Through Obfuscation?

Healthcare is full of terms that obfuscate things. Ironically, use of the word "obfuscate" can be an example of obfuscation.

Instead of saying, "Healthcare leaders often obfuscate a situation," we can say, "The language used in healthcare often makes things sound better or more complicated than they really are."

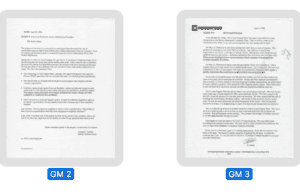

Part 2: 20 Years Ago at GM, the Quality Death Spiral...

Recently, I blogged about a quality catastrophe that I lived through at GM just over 20 years ago, at the now-closed GM Livonia Engine Plant.

Bluntly, the quality problems were caused by poor management and the side effects of their decisions. Even though they constantly blamed workers, management directly interfered with workers and engineers being able to do the right thing for quality.

Here is Part 2 of that story... the first quality "spill" took place in April 1996. As I wrote about last time, Angry high-horse memos were sent out by management. Workers were told to have pride and to pay closer attention to quality (as if those had been the problems).

20+ Years Ago at GM: The Quality Death Spiral of Bad...

My first job out of college was as an Industrial Engineer at the General Motors Livonia Engine Plant. Blogging didn't exist then (I didn't even have email or internet access at work) or I might have started my writing career then. Oh, the stories. I've shared some of them on this blog over time.

I've blogged about papers from the Don Ephlin files, a former UAW national leader. I have my own small collection of documents and artifacts from my days at GM that I thought to keep in a folder. I still have that folder today.

A few of these memos tell the story of a quality and productivity death spiral that eventually led to our plant manager being replaced. And, by "replaced," I don't mean fired or given an early retirement. He was, at least in title, PROMOTED to a role at GM Powertrain headquarters. Thankfully, the new plant manager, Larry Spiegel, was one of the original "NUMMI commandos" and he made a huge difference to the plant and to me, personally.

Clearing the Lean Blog Backlog: Lemmings, Change, Lean, & Leadership

Cleaning out the backlog of stuff I wanted to blog about...

Not Being Lean Lemmings; Why Best Practices Don't Yokoten; Nissan Leaders Lead the Way, After the Problems