Tag: Problem Solving

Going Down — When a Solution to One Problem Seems to...

My wife and I have been home in an Orlando condo building for the past month. In efforts to avoid the coronavirus (and to...

Operational Excellence Mixtape: April 10, 2020

Thanks as always to Ryan McCormick for this...

Healthcare - Creating Value for Patients

Healthcare and hospital staff around the world are working tirelessly to provide...

The Path to Patient Safety in Japan (or Elsewhere): Reporting Problems,...

tl;dr summary: The blog post discusses the importance of reporting and solving problems for patient safety in Japan. It highlights stories from two hospitals...

Operational Excellence Mixtape: January 17, 2020

Healthcare - Creating Value for Patients

Sometimes you just need to get a team together and improve. Here's a good example of use of A3 thinking to...

When Problems are Hidden in Kudos: From Celebrations to Root Cause...

I want to give credit to my friend and colleague Tony Milian for the idea that prompted this blog post. Tony and I used...

The “Smart Loves Problems” TV Ad — But What Does Fear...

This ad caught my attention while watching a little bit of Monday Night Football this week.

It's an IBM ad titled "Smart Loves Problems."

The ad's...

Podcast #348 — Cinnamon Dixon, Tiered Huddles at Cleveland Clinic

Our guest today for Episode 348 is Cinnamon Dixon, Director Of Continuous Improvement at Cleveland Clinic. I interviewed her for the KaiNexus Continuous Improvement...

General Jim Mattis on Leadership, Mistakes, and Defining Problems

General Jim Mattis has been making the rounds to talk about his new book that is out today: Call Sign Chaos: Learning to Lead.

"Learning...

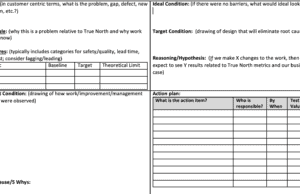

An A3 Approach to Explaining the Case for Process Behavior Charts

I was invited to give a presentation on Process Behavior Charts and Measures of Success at Cleveland Clinic last week as part of their...

I Haven’t Been Following the Best Standardized Work for This Daily...

"The way we've always done it" doesn't mean that's the right way or the best way to do something.

One of my daily habits is...

Webinar Preview: A Structured Approach to Problem-Solving

Please join us on May 16, as KaiNexus and I host a webinar presented by a leader from one of our customers -- Chad...

Operational Excellence Mixtape: December 21, 2018

Mark's Note: I've known Ryan McCormack for many years now, thanks to his previous work in Lean healthcare and his attendance at Lean Healthcare...