Scroll down for how to subscribe, transcript, and more

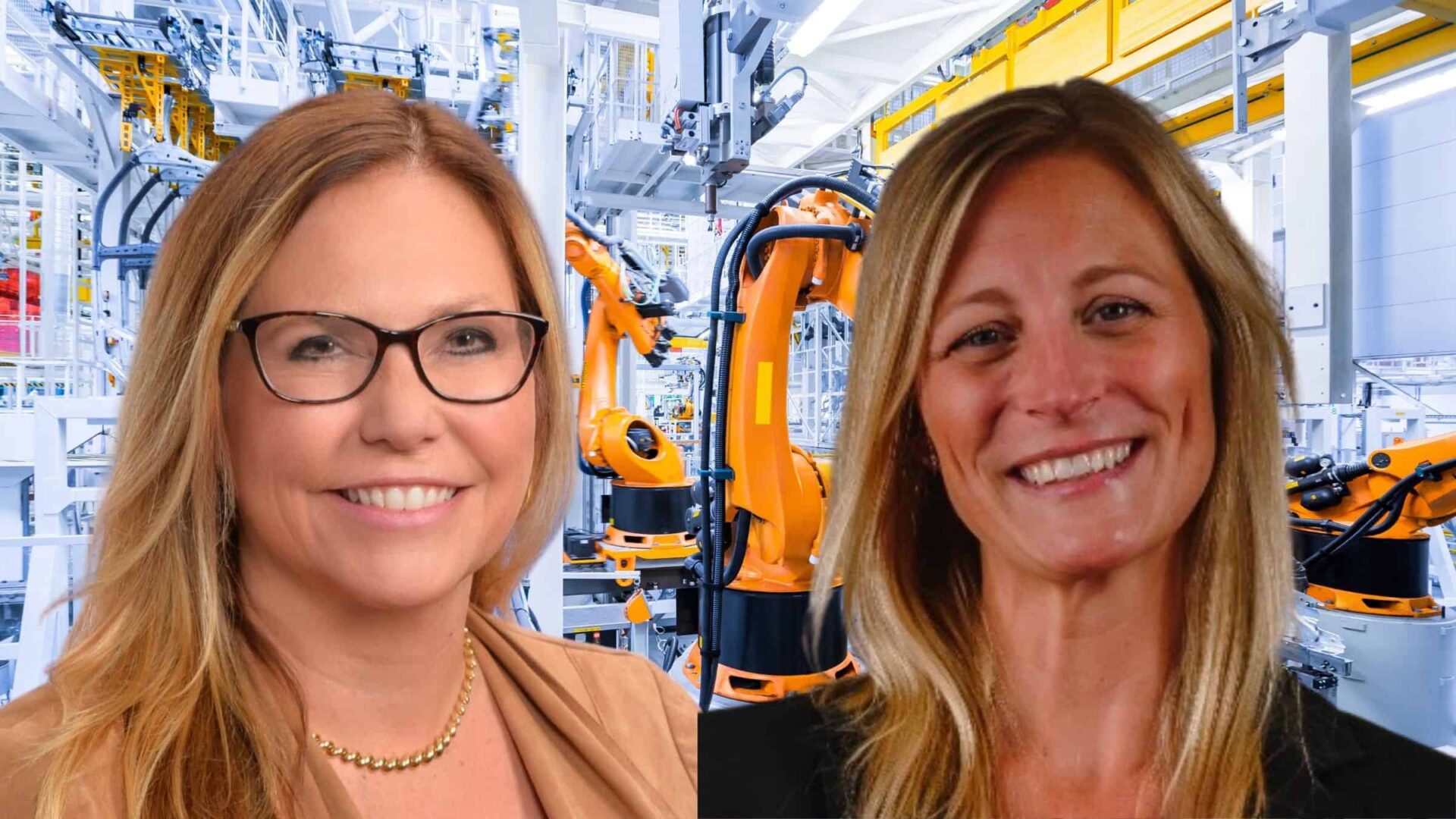

My guests for Episode #438 of the Lean Blog Interviews Podcast are Shannon Karels and Kathy Miller, the authors of the recently released book Steel Toes and Stilettos: A True Story of Women Manufacturing Leaders and Lean Transformation Success. Their website is opsisters.com.

Kathy Miller is a Senior Operations Executive who has held numerous global vice president and director roles both in manufacturing and lean enterprise leadership. Kathy is a Shingo Prize Recipient for Large Businesses as a Plant Manager.

She started her career in Operations as a 17-year-old co-op student at a vehicle assembly plant, and progressed through engineering, marketing, lean, and operations leadership roles, working for four large publicly traded corporations in executive roles.

Shannon Karels is a Senior Operations Manager who has led multiple lean transformations and run operations for two large publicly traded corporations across various industries and business models. She started her career in supply chain management and progressed through lean and operations leadership roles.

Today, we discuss topics and questions including:

- What are your Lean origin stories?

- Kathy – what was the motivation for Lean– catching up to Toyota? Main goals?

- Shannon – starting point, the business was losing money?

- The “right way to run a business” – what appealed most to you?

- Kathy: how to help break old habits and truly embrace what's being taught?

- Other coaches and influences?

- Including Chris Harris, John Shook, Jim Womack

- How did auto experience translate to first job outside of GM/Delphi?

- Story behind the book?

- How much of the book is about issues faced by women in manufacturing?

- The lean facilitator and the General Manager – how do the roles and responsibilities break down in a lean transformation?

- Your passion for safety? Where did that develop in each of you?

- Lean in the office? Carpet land?

The podcast is sponsored by Stiles Associates, now in their 30th year of business. They are the go-to Lean recruiting firm serving the manufacturing, private equity, and healthcare industries. Learn more.

This podcast is part of the #LeanCommunicators network.

Video of the Episode:

Automated Transcript (Not Guaranteed to be Defect Free)

Mark Graban (1s):

Well, hi, everybody. Welcome to the podcast. Again, our guests today are Kathy Miller and Shannon Karels. They are the co-authors of the new book. Then I've got a copy here, “Steel Toes and Stilettos: A True Story of Women Manufacturing Leaders and Lean Transformation Success.” Their website, where you can learn more about the book and the work they're doing now is opssisters.com. so before I tell you a little bit more about each of them, Kathy, Shannon, welcome to the podcast. How are you?

Kathy Miller (32s):

Thanks, Mark. Great.

Shannon Karels (33s):

Thanks, Mark.

Mark Graban (35s):

So Kathy Miller is a senior operations executive. Who's held numerous global vice president and director roles, both in manufacturing and lean enterprise leadership. Kathy is a Shingo Prize recipient for large businesses as a plant manager. And Kathy started her career in operations as a 17 year old co-op student at a vehicle assembly, plant automotive industry and progress through engineering, marketing, lean, and operations leadership roles working for four large publicly traded corporations in executive roles. And Shannon Karels is a senior operations manager. Who's led multiple lean transformations and run operations for two large publicly traded corporations across various industries and business models.

Mark Graban (1m 16s):

She started her career in supply chain management and progress through lean in operations leadership roles. And as we'll learn about, as we talk about the book and the story behind the book, how they worked together, but before we talk about all of that, maybe individually, you know, as I tend to ask guests here on the show to, to hear about how you got started with, with operations and with lean, what was the context for that? Kathy? Maybe if you could answer that first.

Kathy Miller (1m 44s):

Sure. Well, mark, my introduction to operations really started because I needed to put myself through college and I was looking for programs where I could do that. I was good at math and science, but you know, I loved all the classes. I got an application in the mail from GMI, which is now Kettering university. And my dad had heard of it even though he wasn't in operations and had me apply. And it was such a wonderful program in terms of not only financially a great program, because you got to work half the year, but also educationally, right?

Kathy Miller (2m 30s):

And because you got to work half the year in addition to the academics. So that's how I found my way into operations. And I found myself again, starting at 17 years old in a vehicle assembly plant had to grow up very fast back in the day in that environment, but I did fall in love with it. I just found it fascinating that a working vehicle came off the end of the line every 60 seconds. And I always tell, you know, it's too late to be a rockstar. I'd still love to run a vehicle assembly plant because I just think they're amazing systems. So I started there, the plant closed down when I graduated and moved into supply base automotive electronics.

Kathy Miller (3m 15s):

And there I worked in engineering and marketing back into engineering and some of the advanced systems that we find in vehicles today found out I really missed the plant. So after that, I went back into operations and got a call one day from my boss's boss to come see him in the office. And he told me that he was putting me on a lean team that, you know, everybody was going to have one aspect of the lean system that they were going to apply globally. I of course thought I w the special project was some bad statement about my career. You know, why was I being sidelined?

Kathy Miller (3m 56s):

And here it turned out to be, you know, so pivotal to the rest of my career. So served on that team got promoted to plant manager. That's where we worked on transforming the operations and the Shingo award came about for my team. And then I just progressed through other vice president roles of lean manufacturing and quality and strategy deployment. And I went back and forth between running global operations and supporting global operations with the lean manufacturing operating systems.

Mark Graban (4m 34s):

Well, great. Well, I'll come back maybe with a couple of follow-up questions about your early experiences there, Kathy, but, but Shannon, how, how about you, your choice to work in operations and supply chain and your early exposure to lean?

Shannon Karels (4m 51s):

Sure. Well, I started out in with a supply chain degree in Western Michigan, which was a funny story in itself as I went through all of the curriculum and the business college and started just eliminating everything I didn't want to do. And supply chain had this amazing job placement at the time. So I ended up pursuing that and actually found out I was pretty good at it and enjoyed it. And then I got recruited right out of college to a very large manufacturing firm, which I guess I never really imagined myself doing, but then quickly, quickly enjoy being in the plant, working with all the people. And I happened to be working for this division that was losing a significant amount of money every month.

Shannon Karels (5m 31s):

And they said, Hey, we're going to try this lean thing. And I said, okay, let's, let's do it. So, because I was on the supply chain side, I was in charge of material and information flow, and that's how I got introduced to lean. And then going through that transformation, I learned that this is how I really wanted to run businesses. This was the right way for, for me. And then I progressed through other lean leadership roles and then went on to a couple different plant manager roles where I ran those businesses and apply those lean methodologies. And really when I started with a multi-site lean responsibility is when I got really deep into lean and started working with Harris Lean Systems.

Shannon Karels (6m 11s):

And that's where I got the majority of my lean training and really changed the juror directory of my career from there.

Mark Graban (6m 19s):

Yeah. I saw the endorsement on the back of the book from Rick Harris and Chris Harris has been a guest here on the podcast twice. Kind of spread out maybe about a decade apart. It was on here a couple of years ago, so great coaches, and I'm sure you've had a lot of coaches and influences through your lean journeys individually and in these companies. So Kathy, I was going to ask, and then maybe Shannon back to you on the similar question, you know, Shannon, you, you had mentioned the starting point for the company you were at was losing money, business turnaround, Kathy, thinking back to when you, when you were there in the automotive industry, what were the stated motivations for lean?

Mark Graban (7m 8s):

Like, you know, I started at general motors in the mid nineties, there was talk not so much with the frontline workers, but behind the scenes about catching up the Toyota, like, you know, the plant I was in our performance was bad on both quality and productivity and other, other other measures. What was, what was the talk where you were about the reasons for really diving into lane?

Kathy Miller (7m 32s):

Well, at the time I was in the same chair, but general motors said spun off its component divisions. So we were, went from being part of general motors to being a supplier to general motors. And so that put us in a different situation where we had to really be competitive as not part of the parent organization anymore. So it became the operations strategy and the leadership, there was very emphatic about, we are going to do this, we're going to embrace this. And there is no plan B and a, they were very pragmatic about making sure that people are educated in it, that people who really showed an aptitude for it were promoted into leadership positions.

Kathy Miller (8m 17s):

So they could put systems in place that would sustain themselves. They found other opportunities for people who really didn't buy into it. So it was all about being competitive

Mark Graban (8m 28s):

And Shannon, I mean, what are the detail, would you add about sort of the business situation that, that, that company was in

Shannon Karels (8m 38s):

Besides losing money? I think our on-time delivery was abysmal. I mean, we're talking like embarrassing levels and quality wasn't great productivity was terrible. It was all the things. So we really had to do something different and it was kind of that same concept is the leadership said, this is what we're doing. This is our strategy team built a solid team around. It gave everybody pieces and on, we went and learned and tried, and five years later we were making 15% ROS at that point. So it was a significant transformation. I think we on-time delivery went up 50 points. I mean, it was dramatic improvement.

Mark Graban (9m 16s):

Yeah. And you talked about Shannon, this being, you know, the right way, the best way to run a business. And what, what, what were some of the aspects of that that appealed most to you even at that point in your career?

Shannon Karels (9m 32s):

Yeah, I think a lot of it was, well for me, I'm very analytical and all of it was based on math, not opinions. So as long as you had the math, right, there was no debate. And there was no argument about it. It was like, here's the plan. This is what it says, let's go. And the team kind of was able to rally around that. The other piece for me was getting to work with all the people, you know, working with the people on the floor to develop Tucker routes and put parts in the right place in the market based on what was convenient for them. And that sort of early on relationship building for me was, was very important. Yeah.

Mark Graban (10m 11s):

So in talking about math, that's things like supply chain, math around inventory levels and delivery frequencies and good things like that.

Shannon Karels (10m 20s):

All the fun, all the fun things.

Mark Graban (10m 22s):

Yeah. I mean, I, it's kind of I'll, I'll, I'll share these stories similarly time over a, a cup of coffee or a drink bumping back to times again, when I was back in the automotive automotive industry where the math would come into conflict with, you could call it fear or politics or habit, or, or even like feelings. I feel like we need more, if it's there, it can be tough to navigate sometimes. Right.

Shannon Karels (10m 47s):

Especially when you kept finding parts, hidden in drawers. And then all of a sudden they would just like magically appear. We don't, we ran out of parts. Oh, well, I've got a couple over here. I saved. And we would just keep unearthing them throughout the plant because people were so used to running out. And so they would hide them

Mark Graban (11m 4s):

Wow. For that manufacturing rainy day.

Shannon Karels (11m 7s):

Yup. So it was breaking those paradigms as well when we were trying to put this math in place. Yeah.

Mark Graban (11m 15s):

So maybe a question over to you, Kathy, in the leadership roles that you've had, both of what you might call lean transformation roles and as a general manager of a business unit, what are some things that you find work well when it comes to changing habits? I mean, it's one thing to teach people, new concepts, new methods, but, you know, as people would say, old habits die hard. What are some experiences or tips you would share with the audience about kind of on the level of leading change and developing new habits and embrace of what's been taught?

Kathy Miller (11m 52s):

Yeah. That's a great question. There's so many things that you have to do. Right. And in the first plant where I was implementing lean, you had support to the very top of the corporation. So that was great. You know, the fact that they would publicly come out and say, there is no plan B. It wasn't just an idea that I had, right. It was a corporate objective and it was tied to getting competitive and, you know, being competitive is how businesses sustain themselves. So there was definitely a compelling case that we could wrap our head around. So, so that was a big deal. And quite honestly, I couldn't waiver from that.

Kathy Miller (12m 35s):

And I spent a lot of time on the floor, a lot of time with the teams. A lot of times, teaching people how to audit and check. And double-check also spent time making sure that the parameters of what was in a good boat negotiable and what wasn't were set, you know, having some guide rails around that, because it's very important to have people contribute to making things better, the people who do the work, but you have to put some guidelines around that so that your systems have a chance of sustaining themselves. So really making sure we were clear about where we were looking for input and what things weren't negotiable was a big deal, but it took a lot of perseverance, a lot of persistence, a lot of auditing, layered audits until people started to catch on to the fact that, you know, maybe this was a better way of doing business, but you could, you could never let up.

Kathy Miller (13m 36s):

Right. So we'd put a tug around in place. And I would walk with the tugger out the first day, you know, and as the plant manager, right there, 1500 hourly people and 500 salary people. And, you know, people would say to me, thank you for anything better to do today. You know? And I would say, now this is the most important thing. This is the lead off operation in the plant. And I want to make sure that this, you know, Tucker driver knows that they're supported and, you know, find out what problems they have so we can remove roadblocks. So it is not, this type of transformation is not for the faint of heart and you have to be very dedicated and you have to show up, you can't just delegate this.

Kathy Miller (14m 18s):

It won't work. Yeah.

Mark Graban (14m 20s):

And it seems like there's gotta be that compelling business need, like not pursuing lean because it's nice to have, or, or optional, like there's some level of necessity that's required. Shannon. I see nodding your head. What, what are your thoughts on?

Shannon Karels (14m 38s):

Yeah, I absolutely agree. And Kathy, what Kathy said is right, you have to paint a vision, but there's gotta be something behind it. Right? So whether that's you go through strategy, deployment and transformation planning, where you're aligning to corporate goals, whatever that structure may be, there's gotta be something solid behind it that you can rally the troops with versus just, Hey guys, I've got this brilliant idea. Follow me. You're absolutely right. So that way you can not only to compel them to want to come, but then to track the progress and say, Hey, look at how we measure success. So I think that you need both those things.

Mark Graban (15m 12s):

One of the things sort of come back to, you know, Shannon, you mentioned Harris lean systems. One of the questions I like to ask gastro ward, you know, who were some of the other key influences or coaches or trainers, or even if the word sensei comes to mind from your own lean education and progression?

Shannon Karels (15m 35s):

Yeah. Well, besides just, you know, the, the books that we just, when we started, we just, I picked up creating level pole and was like, all right, let's figure out how to size some inventory and buy our, I think it was art Smalley wrote that book and just throw in some combines. So we were, it was just first, it was books and trial and error. And then when I started working with Kathy, she had a ton of experience. And in addition to that, she was leading the corporate lean and quality role prior to, and she had lots of friends. So we had all of our corporate people that were, you know, the new, the new lean sensei that was up there was helping us. Mark was a big help with, for Kathy and I in that process.

Shannon Karels (16m 19s):

And so it's just all these names that come together. And, and to be honest, I learned a lot from our team just from trying things. And there were things that we would like be sitting in a room around the floor and trying to hash out how to, you know, flow through this shared resource. And, and the team would have this like brilliant idea. I'm like, oh my gosh, I never even thought about that. I never read that in a book. This is amazing. Let's try it. So it's hard to pinpoint one person besides besides that power of trial and error.

Mark Graban (16m 50s):

Yeah. And mark, DeLuise also a former guest on the podcast here, but you raise a really interesting point of, you know, that we have the opportunity to learn from other companies. We can learn from people who have done things at other companies. And you've been in that position of being now the person who did things at other companies. And let me tell you about our experiences versus experimenting or trying things based on principles, or maybe even developing your own principles. That's really important thing to think about me. How do you find that balance or get inputs all around Kathy? What would, what, who were some of your coaches and influences that made a big impact?

Kathy Miller (17m 35s):

So again, Harris Lean Systems and I have been transforming plants for almost two decades. Now I was going back and looking at the dates. So, you know, I've worked very closely with Rick and, and more recently with Chris, but Mark DeLuzio taught me a lot about strategy deployment. And, you know, I had the opportunity to teach others about that. John Shook, Jim Womack, Mr. Yamada, you know, all kinds of the people who wrote the books, the early books, you know, we were so lucky to get to learn from them.

Kathy Miller (18m 15s):

So, you know, I've been really aligned with, you know, lean.org and LEI, read, a lot of books, you know, I love Toyota Fieldbook and Gemba Kaizen, and you know, a lot of it you have to learn by doing. Yeah,

Mark Graban (18m 33s):

Yeah. I mean, we can have both, you know, the insights and experiences of others and our own experiments and, and learning Kathy, a question for you, you know, back to this idea of you're coming into a company from the outside, you have experiences and things that you've done and things that worked where you were previously, what are some kind of reflections that come to mind on navigating that as being a new outsider to the company being just from the outside or the first time you worked in something that wasn't as automotive focused or some things that come to mind?

Kathy Miller (19m 14s):

Well, I would say this, nobody wants to hear about, well, this is how we did it at XYZ. Learn that the first time I changed companies. So, you know, I never did that again. When I went to the other two companies, I think the issue is really, you know, establishing credibility with the people who have to implement. So, you know, when I became in charge of lean and quality for the whole company, I had to go out and establish what I call street creds with the people who are now doing the role I had just left. And a lot of that was about rolling my sleeves up and doing it.

Kathy Miller (19m 55s):

And I will tell you that in that particular role where I became the vice-president of lean and quality, I established really good relationships with, you know, the general managers, because I didn't tell them what to do. I understood what some of their challenges were because I was a plant manager who had implemented before. I wasn't just quote unquote booksmart, you know, people don't like, you know, people coming in and, you know, from corporate and telling them what to do. So I think the main thing is just to be able to assess the situation you're going into appreciate where people are coming from, especially people who haven't had, the benefit that you've had of experiencing the benefits of it, be able to being able to acknowledge their challenges and help get to that next level where they're starting to see results and big gains traction.

Mark Graban (20m 52s):

Yeah. Shannon w what are some of your experiences as somebody who's switched companies or moved into different fields?

Shannon Karels (20m 59s):

And I think for me, mine was more around the, I went from a combination of, you know, low volume, high mix to high volume high mix. And then I went, the last company I ran was Lovano like lowest volume. Like we sell seven pieces a year type of low volume. So it was taking the things I've learned in listening. Like I had to learn so much about their business in order to try to apply what I learned in totally different business models to that business model. And for me, it was all about like, you know, like Kathy said, street cred, watching them run the machines, watching them assemble these, these parts and understanding their issues and what was driving problems into my P and L.

Shannon Karels (21m 50s):

And so I think that was for me, the more difficult part, and really the tools I use was just to try to learn and then apply what I learned. And there were times I still couldn't figure it out. So of course, I'd get my team together and be like, how do we fix this? Or I call up Rick and be like, well, here's the thing I've got, what do you suggest I do about this? I want to do this, but I don't know how, and then we would talk through it. So again, it's going back to just that trial and error piece of it. It's not a one plug fits all type of experience. That's for sure. Yeah.

Mark Graban (22m 22s):

So with the book and again, the title is Steel Toes and Stilettos, and, you know, the, the, the story and the focus in the book is, you know, being women in, what has traditionally been a very male-dominated industry. I haven't worked in manufacturing for over 15 years. That's, that's still generally a true statement today. And it's, it's been, how would you describe like, sort of that evolution of, you know, more women, you know, coming through paths of engineering or other disciplines and coming into manufacturing, how has that been evolving?

Kathy Miller (22m 60s):

Well, I think that, you know, there's been a lot of emphasis in the world on diversion, diversity and inclusion and women in stem. There's a lot of organizations now who support that. So I do think the funnel is starting to be filled, you know, at the early stages with more, but there's still very few, at least in my experience of women making it to the senior executive ranks in the operations functions. So there's a lot of catch-up that still needs to be there. And, you know, Shannon and I always talk about when we were growing up in this, there weren't a lot of female role models in this function.

Kathy Miller (23m 43s):

So we were paving the way I think, and our message in the book is it's okay. Right. You can be yourself, you don't have to conform to stereotypes of agender to be successful.

Mark Graban (23m 57s):

Yeah. Shannon, what are some of your experiences and what you've seen through your career? Yeah,

Shannon Karels (24m 4s):

I would echo what Kathy said, some of my experiences too, as if there were women, and I'm not saying this as a blanket statement, but just in some of my experience, if there were women that have reached that level, in some cases, they, their husbands did not work. And so it was a very different experience for, for me, especially working with Kathy, to be able to understand what that was like with a dual career marriage, and then adding children on top of that, it was definitely different in there. Weren't a ton of role models as Kathy said, for what we've experienced. I do think now Kathy is absolutely right. The funnel's filling. And I think that we are in a position to have more of those role models for that next generation,

Kathy Miller (24m 49s):

But we will always say, you need to put the best person in for the job, regardless of age, gender, that sort of thing. That's always been my motto. I know that Shannon feels the same way. I know that, you know, through the years, when I think about it and step back and think about it, I had some pretty diverse teams, but I think it was because I had really good candidate pools because people wanted to be part of inclusive teams where everybody didn't look and think the same way, you know? And so that allowed me, you know, to pick the best people, regardless of, you know, their gender or any other category that you'd see on these diversity pie charts that get thrown up all the time in HR meetings.

Mark Graban (25m 43s):

But, but now as you've been through this path, and I know, you know, part of the story in the book, it sounds like is, you know, your working relationship, the two of you, Kathy and Shannon and, and, and, and this book is ma you know, a step toward providing, even from afar mentorship, to other women who may be starting their careers, or earlier in their careers in manufacturing, is that how much of that was a driver for writing the book, as opposed to the lean transformation story that's also of course, contained in the book.

Shannon Karels (26m 17s):

Yeah, that's a great question. And I think we really started with who are we writing this for? And we did start off with that young girl who wants to get into maybe manufacturing or stem of any kind, and that we, we want to be role models for them. We would like to be, to show them that you can have the proverbial all, I suppose it just takes a lot of balance. And quite frankly, it takes a good support system to be, to do it too. And Kathy and I found that in each other and still find that in each other, as we've gone through all these different careers in life changes together.

Kathy Miller (26m 50s):

Yeah. And mark, you're you're spot on. Right. You can read this book two ways. There definitely is a roadmap in terms of an order in which we implemented the tools and systems. And sometimes it was one step forward, two steps back, right. To make things sort of things that sustained. So it definitely can be read that way regardless of gender or what function you're in. Cause you can use a lot of these tools outside of a factory too, and other kinds of businesses, but just along parallel path with that is, you know, women in stem and women in leadership.

Kathy Miller (27m 31s):

And so Kay to be authentic. And do you, you know, you can still get really great results.

Mark Graban (27m 38s):

I mean, it soon, like maybe there's a parallel when we think of trying to be successful as a company through lean or as a healthcare organization, we, we, it's natural to try to learn from others. Who've gone before you and to emulate others versus finding your own path as, as, as you've touched on here with your own experiments and finding your own way with lean, is there a similar dynamic of, you know, navigating a manufacturing operations environment as, as a woman?

Shannon Karels (28m 11s):

I think there's, yes. I mean it's different, right? It just is. And that's okay. It just is. And so Kathy and I talked a little bit about some of the challenges we face as women. We, interestingly enough, never really talked about it when we were going through this process, we just were there to do the hard work. And, you know, there were times when her and I did not get along and did not necessarily agree on something, but what we found was we handled it mostly constructively and then, you know, the next day we were, we were great. We were good. We were there for the greater good, right.

Shannon Karels (28m 51s):

So it's, it's, it definitely makes a difference, I think, and you get comments that maybe aren't necessarily appropriate and you just learn to kind of deal with them. And I think in this day and age, it's starting to be a little more recognized as maybe being a little inappropriate, but we just kind of took it as, Hey, you know what? You can't bring us down, we're going to get this done and we just powered through it.

Kathy Miller (29m 18s):

Yeah. I think that, you know, more of our reflections about being women in stem or art or retroactive now. Right. So when we're in the moment, I would rarely think about the fact that I was the only woman in the room that, you know, for most of my career, I was the youngest and only female on every staff till, you know, the 10 years or so, unless there was someone in HR or finance. Right. So, but I just never thought about it unless somebody made a comment to me about it and made it an issue, you know? So I think that's, that's the difference. People make a lot of, I think well-meaning comments that make you feel like, oh yeah, I guess I am the only woman in the room, you know, or I'm the youngest in the room or whatever the case may be.

Kathy Miller (30m 10s):

But I never felt like that was a reflection on why I was in the room. You know, it was felt like I had earned my seat at the table. I had amazing mentors and bosses who gave me opportunities probably before most traditionally would have and believed in me and instilled that confidence in me. So like I said, the gender thing really wasn't for foremost, in my mind, unless someone brought it up, you know, and then I would generally slough off something about, you know, the advantages of small lines at the bathroom during meetings, you know, what are you going to do? It's the only place in life or, you know, that's an advantage.

Kathy Miller (30m 50s):

So, you know, things like that, we didn't make it like a big contentious issue. Yeah.

Mark Graban (30m 56s):

Yeah. But there's, there's a different layer of now navigating the work life that, that I won't ever have to face and think of, you know, I can think of myself as an engineer or a consultant or a podcaster. And there's not that layer of also being pointed out as being, you know, somewhat rare or unique like, oh, well she's a woman executive. And you say, well, why not just executives or there's, you know, it being one of a few in that role or, you know, sometimes this comes up, you know, regarding race of somebody feels like, well, now they're in a position of having to represent everybody.

Mark Graban (31m 38s):

A pressure of, you know, comes from being different and being in a high high-profile position. But what I hear you saying is, you know, you, you were focused on as much as you can, you know, the work, the transformation, the business,

Kathy Miller (31m 53s):

Yeah. A hundred percent. I mean, there was one company that I worked at that was, those comments were so pervasive, right. About being the only female ops person or, and it, it did tend because it was so pervasive to put a different level of pressure, like, you know, oh my gosh, if my performance is going to make or break, you know, women in operations for the rest of eternity, but Y Y you can't allow that to get to you. That's their issue, not your issue, right. You're at the table because of your contributions and what you have to bring. So that part can be challenging, you know? And I just got to the point where I would again, use what I thought was funny humor to try and deflect some of it, like, you know, Hey, I'm not a unicorn, I'm just a person here to do a job, you know?

Mark Graban (32m 43s):

Right. So sometimes other people put that focus on you or white. What I hear is saying, am I hearing you right? That sometimes people would make comments. They thought were supportive, but were inadvertently just deaf could downsides,

Kathy Miller (32m 59s):

Like, I'll give you an example. There was a new executive at one company I was with and I was help hosting him, you know, through the day at various plant visits and, and meetings and whatnot. And the moment that the meeting, the people from the meeting left, the first thing he said to me was, wow, not a very diverse crowd around here is there. And so I'm sure he was, well, I'm not a mind reader. I don't know what he was thinking, but I had to say in my mind, huh, if Joe were the person who were, you know, escorting you around and, you know, being your host, would that have been the very first comment you would have said when people left the room.

Kathy Miller (33m 46s):

So that's just an example.

Shannon Karels (33m 48s):

Yeah. And I have a similar one where I met an executive and they're like, oh, you know, this is Shannon. She's, she's the plant manager here, blah, blah, blah. And they shook my hand and said, oh, wow, good for you. And I was like, thank you. I mean, yes, good for me. But like, yeah. So it's just those types of things that you just kinda, you know,

Kathy Miller (34m 11s):

What are you going to do? Yeah. Yeah.

Mark Graban (34m 15s):

You do your best to shrug it off, I guess. Yeah.

Kathy Miller (34m 19s):

And get back to the business at hand. Yeah.

Mark Graban (34m 21s):

So that business at hand, you know, lean transformation, you know, talking about two roles that work really closely together, it seems in different organizations, the general manager and the business unit had the plant manager, whatever level of the organization, somebody with the broader business P and L responsibility. And then you have somebody maybe you could label as the lean facilitator or the lean specialist. How, how did, what do you recommend in terms of finding the right fit roles and responsibilities of those roles in lean transformation?

Shannon Karels (34m 60s):

This is a great question because we've got, we've got Kathy and I have stories for everything, but

Mark Graban (35m 6s):

This is

Shannon Karels (35m 6s):

Right. And Kathy tells the story in the book. And so I won't, I won't steal it, but I want you to, I want you to chime in cast, but like, I, you know, I was a supply chain major. I worked in supply chain for eight years before I started in lean. And I just happened to be good at analytics and communication. And, and some of the key things that were, you know, helped in that role. And so I think it's at least from my perspective, when I've hired other lean people, I'm looking for a good project manager, someone who can be confident when they're coaching at any level in the organization, because lean obviously goes everywhere.

Shannon Karels (35m 53s):

And I look for somebody who can be hold others accountable and has that confidence to do that. And that can learn. Right. Cause you know, one thing that Rick always taught us is like, you can't teach somebody who already knows everything. So, and I certainly wasn't that person. And so I always look for somebody who was interested in learning at the same time as teaching. So I don't, it's hard for me to say there's a prescriptive type of a person to look for. And in fact, one of our best lean engineers was a math major and I never really worked in a plant before. And he was, he was amazing at it.

Kathy Miller (36m 30s):

Yeah. So I, you know, mark, I believe I heard on one of your earlier podcasts, you're an industrial engineering major too, right? Yeah. So I am too. So I think industrial engineers make the best lean people in the world, but let's face it. There's not, you know, there's not armies of us out there. What I look for in a lean person as, as my lean expert right on my staff is first of all, somebody who is promotable and or wants to go back and lead a function, you know, that sort of thing.

Kathy Miller (37m 12s):

Because I think that people who rotate in and out of those positions really help an enterprise become lean. Right. So if you have somebody who wants to just do lean the whole rest of their lives, I, I don't see how that gets put into the organization. Right. Systemically. So I want people who are, you know, high potential, high energy, the ability to learn and teach. And quite honestly, I want people who have strengths that I don't have. Yeah. Right. So I'm a strategic running the business, you know, balancing all the plane plates.

Kathy Miller (37m 52s):

I want someone who I can give a vision to and they can figure out the details, you know, and go get it done. So, you know, I think it's really important. I think one of the issues with the diversity and inclusion quite honestly, is that diversity of thought. And if we just bring people on our teams who are like us, we're not going to get the best results. So, and, and I loved, loved, loved, loved when Shannon came on the team from a material and information flow standpoint, if you don't get those right, you know, you can't truly do lean, but after she got promoted to a plant manager, the next person I had was a person who was very good at analytics and had done the pricing function.

Kathy Miller (38m 40s):

Right. But that person was another person who I saw could do analytics and get things done and move mountains and people. So, and then she, you know, spun off and, and did other things as well. So that's what I look for, you know, and I D I don't think everybody has to have an engineering degree to be a good lean leader.

Mark Graban (39m 3s):

I have experienced that in many different settings. So yeah, I have a bias towards industrial engineers, but, you know, I think if somebody in the last manufacturing company I worked with, he came from HR. So he was a bit of a minority of being a man in HR. I learned a ton from him as I was trying to get better at coaching and leading and developing other people. And he was doing a great job with lean practices within the HR function to solve, you know, meaningful business problems for him. And as I've been in healthcare, you know, partner up industrial engineer and a nurse, or, you know, different backgrounds like that, you, you can learn a lot from each other and get a lot done, but you know, it's a followup Kathy, and maybe Shannon, you have thoughts on this too.

Mark Graban (39m 49s):

What are you you're describing that lean expert, that lean facilitator role as being a developmental role of like somebody who was an area manager, then they may go into that lean role and then they might step it back out after a couple of years into a larger, more direct line leadership role.

Kathy Miller (40m 7s):

Yeah. I mean, I think that, I think that's the best model. If you're looking at a whole company, I think it's good to have a core team of lean experts of people who are that book smart, right. Who want to write the training, who get all the calculations can be called in for the hard problem solving things. But I think 80% of your team needs to be rotational, right? So people can get in, they can get immersed in it and understand it so that then they can go out and apply their thinking within their functions, in their operations, but having a core team of people who that's their favorite thing to do, isn't bad. But I usually like to keep that amount to, you know, use the 80 20 rule and keep those people in about the 20%, because you need people who can develop those street creds with people going, yeah.

Kathy Miller (40m 58s):

I made 10,000 parts a day and converted everything, you know, to a lean system. So that's my thoughts on it. That's worked well for me. That's how I was brought up in that model. Always worked for me. Yeah.

Mark Graban (41m 12s):

One other question for you, Kathy, is, you know, thinking through, and, and Shannon doing maths of CT two as well. What, what are things, I think you said something earlier, Kathy, which is why I thought of you, first of the things that cannot be delegated. So it comes to let's say lean transformation or business transformation. What are some of those things that the general manager cannot or should not delegate?

Kathy Miller (41m 39s):

So the layered audit process, I think a general manager, plant manager has to be out there and see the things for themselves. You know, I really do, you know, go to those, the big plant daily meetings. She can't be in every single detail and still do the strategy pieces of it. Right. But you have to be seen you, can't just say, you know what? I don't care about that, you know, go do that, come back and tell me when it's done, you know, and in certain types of problem solving also, particularly in the industrial world, I feel that if you're going to have respect for people, you have to provide both physically and psychologically safe environments.

Kathy Miller (42m 25s):

So if we had a safety accident, I was always personally involved with reviewing the corrective action at the site of the accident and bringing my whole staff along, even the marketing people and, and the other people, because everybody deserves to go to work safe and get home safely. So that's another thing that cannot be delegated.

Mark Graban (42m 46s):

That's a great point. Shannon, what's your view on, you know, things that the general manager cannot or should not delegate?

Shannon Karels (42m 54s):

Yeah. And my, my views don't differ much from Kathy's. I mean, especially in the beginning of a transformation, you have to be present to show that you're serious about this happening. And, and quite honestly, you have to know what's going on in the beginning because you're developing a team, you may hear different things and you need to be able to see and have that again, that credibility that you know, what's going on in your facility and with your team members. And I also found in the beginning of, of this whole process is you start to, it's important to be there so you can see how your team interacts. So is there, you know, somebody who's dominating and everybody else's just listening or is everybody getting, you know, to be able to participate?

Shannon Karels (43m 38s):

It's, it's a lot of that. And you want to drive more conversation through questions versus telling everybody what to do. So I think that it's just piggybacking on what Kathy said is those are the things you, you need to be present for those until in my opinion, as you're progressed through the transformation, eventually it's not just one lean person who's driving it, or the plant manager or general manager, the whole team's thinking that way. So then you can kind of step back a little bit and say, Hey, I've got confidence in you guys to solve this problem without me being, you know, attached to you anymore. And the business starts to grow that way, where you can start to look more on customer relationships and growth and things that pull you in different directions versus just the operation.

Mark Graban (44m 21s):

And you mentioned safety. And one thing I wanted to ask about, there's a section in book that talks about, you know, passion for safety. And, you know, I think we're, we're, we're in agreement maybe with the audience we're preaching to the choir about the importance of safety as a precondition focusing on, on that Toyota preaches that, and people I've worked with who've come out of there really emphasize that through action. It's not just preaching of course, but you know, sometimes we're, we're trying to help move others along who might agree on some level.

Mark Graban (45m 1s):

Sure. Safety is important, but, but what, what makes it a passion for safety? Where, where, where did that come from for each of you?

Kathy Miller (45m 9s):

Well, you know, the first plants that I worked with had UAW workforces and, and I've had UAW workforces and union workforces on and off through my career. And the one thing that I always thought was so powerful very early in my career was there was never a debate about quality or safety being important. And so, well, you could have negotiations about wage rates and shop rules and those sorts of things. I found that it was one area of, of common ground, right. Of a passion that we all felt like we had to protect our people and our products.

Kathy Miller (45m 55s):

So, you know, there's something about some of your early lessons learned. And also, you know, through the years I've witnessed some pretty serious accidents and heard about them and, you know, and in one case I was part of handling a fatality that happened somewhere. And, you know, I had to clean out the locker of the employee with his boss when that person, you know, didn't go home and that's the absolute worst case scenario. It, it wasn't in my unit, but I was a member of the company handling it.

Kathy Miller (46m 37s):

Cause I was literally close to it. And it was life-changing and, you know, I never wanted anyone to get hurt on my watch. I was, you know, it just, I never questioned that. It was just so basic in terms of, if you love and respect people, then you have to provide safe environments for them, you know? And it's not, it's not negotiable. Yeah.

Shannon Karels (47m 0s):

Yeah. I agree with everything Kathy said. And unfortunately, when you experience a serious accident, it, it changes your perspective on any, on the whole entire thing. Now, my passion for safety came in well before I had to experience a very severe accident, that wasn't my plan that I had been running for three weeks. And it was, it was awful, absolutely awful. And prior to that, and then from that point forward, you know, w when we're driving these lean transformations and we talk about respect for people, we're getting to know these people on a personal level.

Shannon Karels (47m 40s):

And that was important to me. And that was something that Kathy really taught me was, let's stop talking about it. Like, oh, you're not wearing your safety glasses. Let's start talking about it as a cultural thing. Like, Hey, you know, I know you're coaching your son's baseball game this week. I want you to be able to see him hit the ball. So can you please wear your glasses? But it became more personal because we were knowing each other outside of our job functions. We were knowing each other as people. And so that's how it became so important to me. And then unfortunately, when I had that serious accident in my facility, only being three weeks there, my dedication to safety and what showed that team from that point on was a non-negotiable item.

Shannon Karels (48m 21s):

And so it brought all of us together in an unfortunate way, but it brought us all together to start to look out for each other, not necessarily just the repairs around the floor.

Mark Graban (48m 31s):

Well, thank you for sharing those stories and those, you know, those reflections that remind us why this is so important. This is not just data points on a chart about lost Workday cases or what have you. This is, this is people and their wellbeing and their lives. So again, we're, we're talking to you before I wrap up again, we're joined I'm Sharon Karels and Kathy Miller authors of the book, Steel Toes and Stilettos. And there's a clever construct to each of the chapters sort of themed around a different type of shoe, not just those to tap shoes and rain boots and cowboy boots, or cowgirl boots,

Shannon Karels (49m 17s):

Whatever fits your feet

Mark Graban (49m 19s):

In this case. But one of the last thing I wanted to ask you about was the environment where the stilettos might be more likely worn the office or what some people call carpet land. I'm curious to hear a little bit, if you could touch on, so your experiences or lessons that come from again, this is different, you know, sort of like coming from the automotive industry to a different industry or from one company to another, coming from the shop floor into the office can be quite a leap. That's a different environment, but I think we would agree lean would apply.

Mark Graban (50m 1s):

Where would your, some of your experiences or lessons learned there?

Kathy Miller (50m 4s):

Well, if you're in a factory environment and you're truly going to be a lean organization, it doesn't take very long before you realize that some of those functions being performed on the carpet are essential to your wellbeing. So you're going to get, you know, when you've got three weeks to produce a part in the first two weeks are creating a part number and getting in the system, and you've only got a week to get it through all your processes. You know, you get there pretty, pretty darn quickly, but even outside of a manufacturing environment, right? Some of the experiences are people really value their creativity. And so there's an initial urge to resist, you know, to feel like some of the processes really inhibit creativity.

Kathy Miller (50m 51s):

And we also found that, you know, we're in manufacturing, you're measured every which way to Sunday people in the office are not measured typically, you know, as often and as much. So there's a few challenges with getting open minds and again, setting those guide rails of, you know, what you are an engineer and you are creative and you know what I want you developing this compound or designing this part, spending your creativity there, not on creating a new filing system every time you put a drawing in place. Right? So when you start to find things that people can find value and measure that are meaningful, it starts to come together.

Kathy Miller (51m 33s):

But that's definitely a difference between a factory in the office because, you know, factories are used to being measured on every single thing and everything's visual in general, right? Yeah. So those are some of the things, but there's so much opportunity in a non-factory work. And when you start, it just becomes astonishing. And once people get the taste of it, yeah. It generally does take a life of its own and, and, and can accelerate.

Shannon Karels (52m 2s):

Yeah. And we, Kathy and I found some unique ways to motivate people and to doing things like office 5s, which is a lot different than doing it on the floor. And we would motivate them differently and amp up our energy way higher than you normally would. And then, you know, a lot of times we started with just basic problem solving in the office. So tackling a problem, people were genuinely genuinely having. And then from there we said, okay, well, if this is one problem and one teeny little thing we can fix, what if we map the whole thing and imagine what this amazing team could solve?

Shannon Karels (52m 43s):

So it does require a little finesse. And then it also requires a lot of conversations with people and listening to their issues and then, and then talking about, okay, well, what, what can we do and getting their input versus, Hey, here's this really cool tool we can use. We're going to do this. We're going to put an operator balance charts on the floor. It does require a little more discussion and finesse.

Kathy Miller (53m 5s):

And I would say this applies in factories, as well as on the carpeting or other industries, you have to make a safe environment to have a more productive environment, not just the physical safety we're talking about, but if you're getting more productive, you know, 20%, and then you lay off 20% of the people, that's going to kill the initiative right there. You've got to have an agreed upon plan of look, we're going to enter purchase orders, 20% more efficient. And you know what, we're going to deploy people to accounts to get more sales so we can grow and, and articulate a great future because otherwise people will resist it either openly or not so openly.

Kathy Miller (53m 51s):

And, you know, I think that's really key. That's really key because there's so much productivity to be had, but you want it being invested into the business.

Mark Graban (54m 3s):

I mean, w w would you say maybe as a final final question here, I'm guilty of asking multiple final questions sometimes, but like what you say keeps prompting other ideas, the, the, the open questioning or challenging of things, do you, do you find that easier to deal with then sort of that subtle under underground resistance, if that's the right

Kathy Miller (54m 28s):

A hundred percent, a hundred percent, you know, Hey, we grew up in and around operations. So we're comfortable with conflict as long as it's constructive and not personal, or, you know, taken over the line. I would much rather have a person argue with me about why I changed something or why something was moved or why this is the dumbest idea ever, because then at least I know what I'm dealing with now. I may or may not be able to change their mind, but nothing is worse than sitting in a meeting. And everyone's like, yes, Kathy, go raw. And you know, you go out and they've done the opposite or haven't, you know, so yeah. I'd much rather have passionate people confronting me than the, what do they call that a pocket veto?

Mark Graban (55m 15s):

Yeah. Or that, that passive aggressive I'm nodding. Yes. But I'm saying, I'm thinking now,

Shannon Karels (55m 20s):

When we would start projects, problem solving anything, we would, one of, one of the ground rules I always put in place was no silent disagreement. Like let's, we've got a safe space, let's hash it out and everybody's got to walk out now, you don't have to necessarily agree. You don't have to be super excited, but you can't be a blocker. You got to go with it and you can't be talking bad about what we're going to do, because it just spreads that negativity throughout the business.

Mark Graban (55m 44s):

Yeah. And as you've been saying in Kathy, you meant you had brought up psychological safety earlier, you know, creating that environment where, or inheriting an environment where people were already comfortable speaking up and not stifling. That is key. Like you said, hashing it out, working through it better to hear the complaint then to have that become the passive-aggressive undermining of, of something. So lessons well learned. And hard-fought the challenge

Kathy Miller (56m 16s):

For sure.

Mark Graban (56m 16s):

But I'm glad you, I'm glad you both could share not just your personal stories and story working together, but you know, the story around lean transformation that's captured here in the book. So again, off the, the book is titled “Steel Toes and Stilettos: A True Story of Women Manufacturing Leaders and Lean Transformation Success.”, Shannon Karels, and Kathy Miller. And I'll tell you in my household, as we talked about earlier, being able to read this book from different perspectives, my wife who's a woman manufacturing leader is reading the book and maybe we might have to, I think we can share it.

Mark Graban (57m 2s):

I mean, w w w we can buy our own copies. That's good for you as authors, but either way people read it, there are different, a lot of different lessons to draw out of the book. So I hope people will check that out. It is available now. And Shannon and Kathy's website again, is opsisters.com. We'll have that in the show notes. So Kathy and Shannon, thank you so much. You know, we, we scratched the surface of all the wisdom and the stories that are in the book. So thank you for sharing a little bit and having a great conversation. And I hope people will go by the book.

Kathy and Shannon (57m 37s):

Thank you, Mark. Appreciate your time, Mark. Thanks so much.

Thanks for listening or watching!

This podcast is part of the Lean Communicators network — check it out!

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s build a culture of continuous improvement and psychological safety—together. If you're a leader aiming for lasting change (not just more projects), I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s talk.

Join me for a Lean Healthcare Accelerator Trip to Japan! Learn More