My guest for Episode #366 is Harry Moser, founder of the Reshoring Initiative. We talk about “reshoring,” in general, and why that's such an important issue in the context of the Covid-19 pandemic and beyond.

Harry definitely falls into the category of guests where I wonder, “Why haven't I had this person on the show before?” Harry and his work have been on my radar for a long time. I appreciate the mission and I wish more companies would consider the “Total Cost” (and old Dr. Deming concept) when making manufacturing site location and sourcing decisions instead of focusing only on “unit cost” or “landed cost” (which includes freight and taxes).

“The mission of the Reshoring Initiative® is to bring good, well-paying manufacturing jobs back to the United States by assisting companies to more accurately assess their total cost of offshoring, and shift collective thinking from offshoring is cheaper to local reduces the total cost of ownership. “

Harry was inducted into the Industry Week Manufacturing Hall of Fame in 2010, based on his long career in manufacturing. He founded the Reshoring Initiative in 2010. Be sure to check out the TCO Estimator tool that he discusses in the episode.

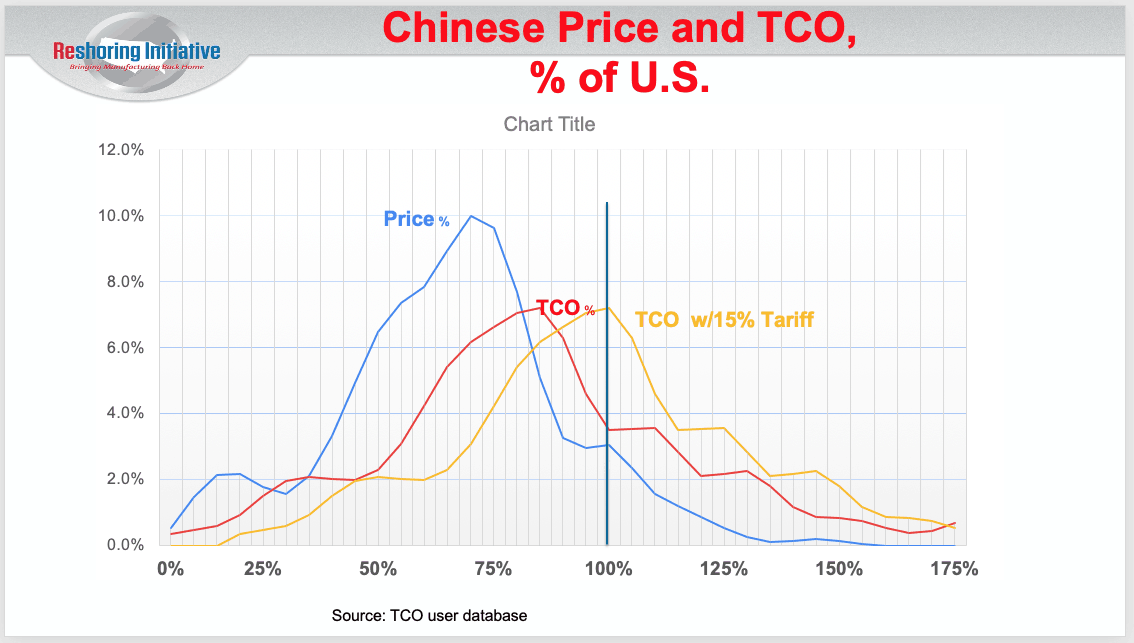

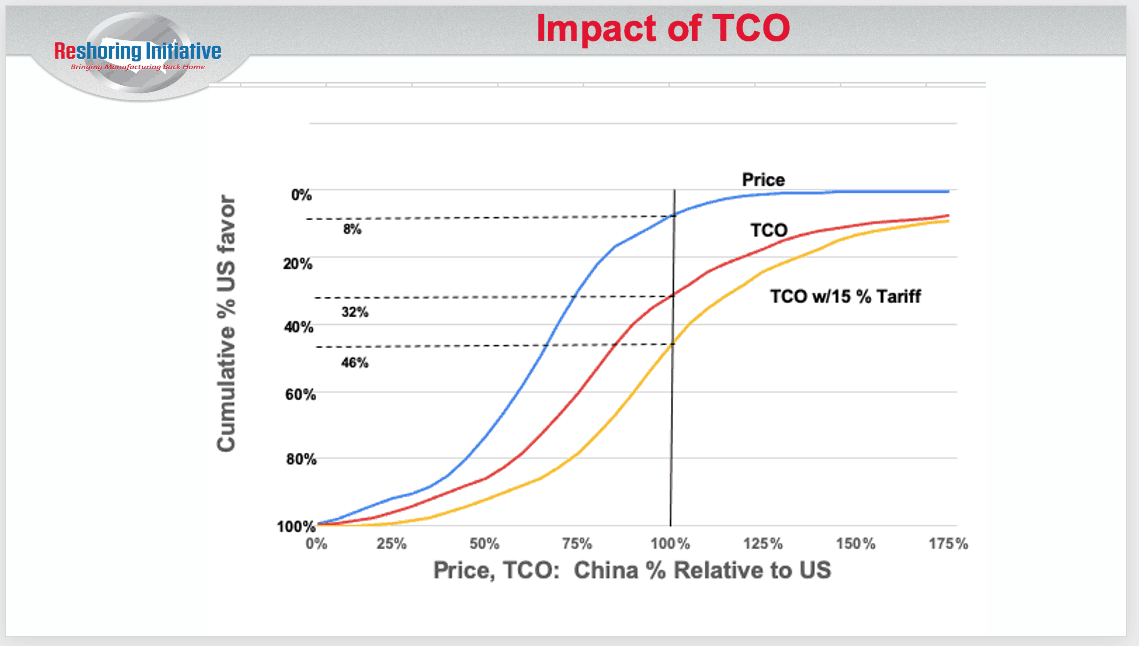

“Most companies make sourcing decisions based solely on price, oftentimes resulting in a 20 to 30 percent miscalculation of actual offshoring costs.”

The Reshoring Initiative

Streaming Player:

Video of the Conversation:

For a link to this episode, refer people to www.leanblog.org/366.

For earlier episodes of my podcast, visit the main Podcast page, which includes information on how to subscribe via RSS, through Android apps, or via Apple Podcasts. You can also subscribe and listen via Stitcher or Spotify.

Questions, Topics, Quotes, and Links:

- The Reshoring Initiative Website

- Harry's LinkedIn Profile

- @HarryMoser on Twitter

- @ReshoreNow on Twitter

- The Total Cost of Ownership Estimator

- Listeners have probably heard of “offshoring” but what is “reshoring”?

- Why “reshoring”?

- What is “nearshoring” and is that nearly as good?

- Tell us about the history of your organization, the Reshoring Initiative…

- Why should our current Covid-19 crisis be a “wake up call” about where goods are manufactured?

- Do you think it's fair when analysts or the media blame “just in time” for shortages of goods and equipment during this crisis (in healthcare or retail)? Why or why not?

- Can Lean take out enough waste to make a high-labor manufacturing site competitive with U.S. wages?

- Dan Markovitz question (paraphrasing): Is moving production back to the US easier said than done if we don't have the skills or the supply base here anymore?

- How can we help companies (and investors) realize that “lowest total cost” is the goal, not “lowest labor cost” or “lowest piece price cost”?

- Why have companies miscalculated when doing the math about moving production to China?

- How can companies use TCO to increase sales?

- Can you give some past examples of reshoring and the benefits?

- What can/should the government do to accelerate the reshoring trend?

Slides Shared by Harry:

Thanks for listening!

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

I’ve never heard of the Reshoring Initiative before seeing this blog post. I thought it was very fascinating to hear about! I found it very interesting that Harry talked about how the supply chain gaps could help companies overcome supply chain problems with manufacturing. I do agree that the COVID-19 crisis should be a “wake up call” for where goods are manufactured.