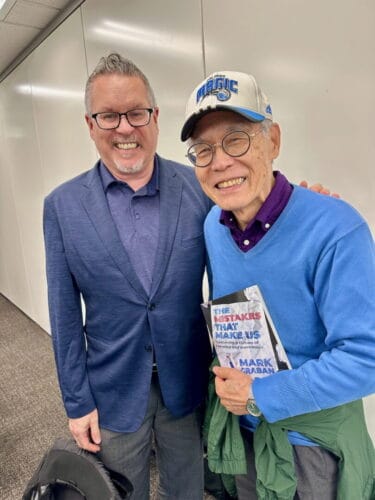

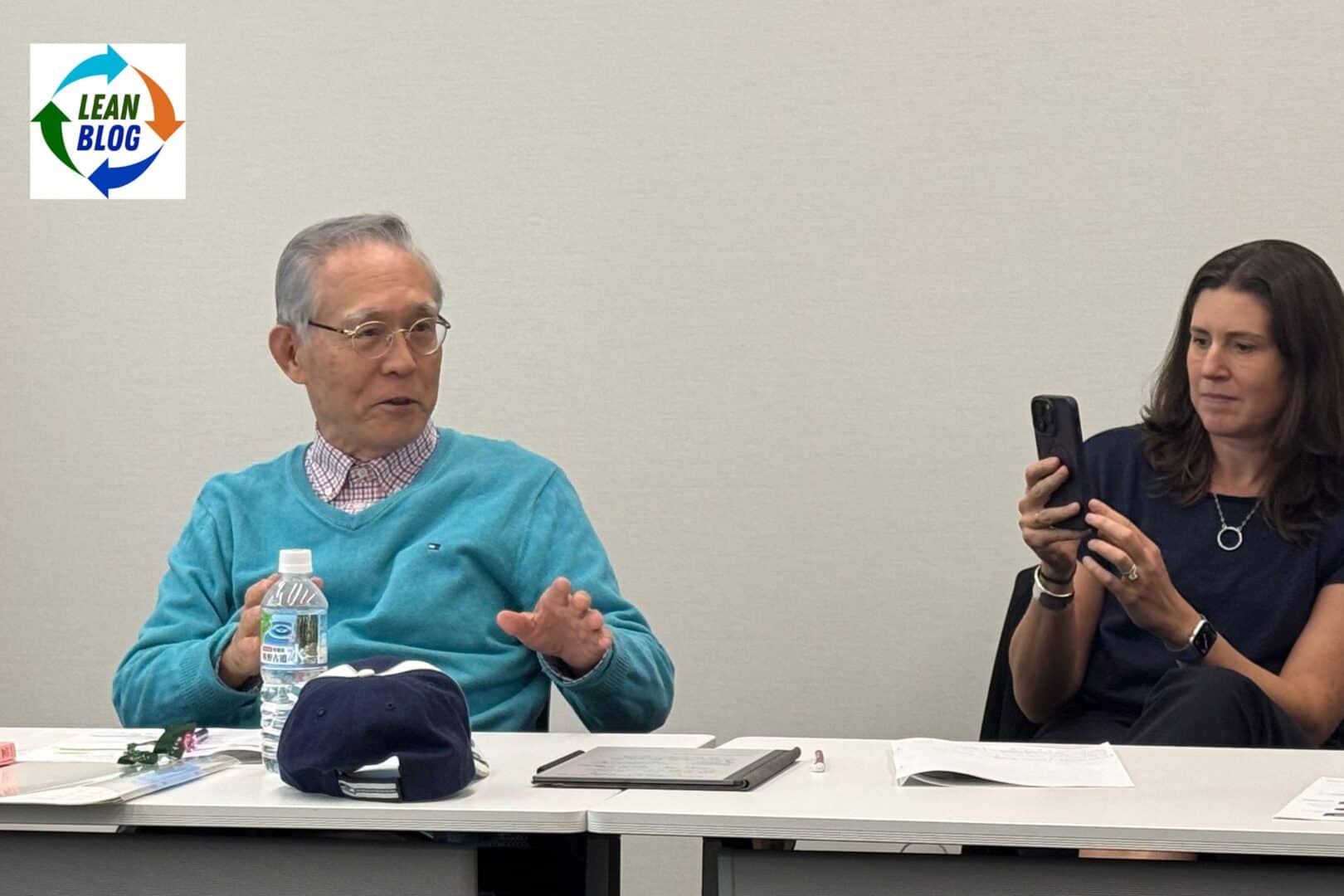

The NUMMI (New United Motor Manufacturing, Inc.) experiment remains one of the most remarkable stories in automotive history. As part of Katie Anderson's fantastic Japan Study Trip that I experienced last November, I had the opportunity to ask Mr. Yoshino about his experience at NUMMI, where he played a pivotal role as the training manager at the very beginning.

His reflections reveal valuable lessons about leadership, learning, and the power of culture change.

The Context: U.S.-Japan Trade Friction and Toyota's Move to America

In the late 1970s and early 1980s, tensions were high between Japan and the United States due to trade imbalances, particularly in the automotive sector. As part of a broader effort to address these concerns, Japanese automakers began establishing manufacturing operations in the U.S.

Honda set up a plant in Ohio in 1982, followed by Nissan in Tennessee in 1983. Toyota, after negotiations with General Motors, opted for a joint venture with GM, leading to the creation of NUMMI in 1984–the re-opening of the failed GM Fremont factory.

“Well, thanks for asking because that was the first experience for me and for most of the Toyota people,” Mr. Yoshino said. “In those days, as you know, trade friction happened between U.S. and Japan, and U.S. Government tried to do something to protect American industry.”

A Struggling Workforce Finds New Purpose

The Fremont, California plant that became NUMMI was previously a GM facility with a notoriously poor track record. Productivity and quality were low, and labor relations were combative. Managers and workers rarely communicated, and employees were disengaged.

When Toyota took over, Mr. Yoshino was assigned as the training manager. He oversaw a bold initiative: sending NUMMI's frontline leaders–group leaders and team leaders–to Japan for an intensive three-week training in Toyota's production system.

“The plan was only three weeks. For some reason, they decided, OK, we're going to send them… They said, we're going to send just three weeks, send 30 people as a big group to Toyota for training,” Mr. Yoshino explained.

“Then three weeks is not good enough to train somebody's mindset. Because GM mindset was so different. Managers and labor did not communicate. That's what we heard.”

Three weeks is a short time to change deeply ingrained mindsets, but something remarkable happened.

The American workers quickly realized that Toyota's approach–centered on respect for people, teamwork, and continuous improvement–wasn't just effective; it was more fulfilling.

“Just right after three weeks of training, only three weeks of training, their mindset–workers, all those people's mindset–dramatically changed,” Mr. Yoshino recalled.

“They just understand that Toyota management style is good. They're not saying that GM style is bad, but Toyota style is more comfortable and makes us feel good.”

I think Mr. Yoshino was being incredibly polite. I worked at GM from 1995 to 1997 in a factory–and I'll say the GM management style was bad. I'd use stronger words than that, but then I'd end up cursing. I should add that I also worked for a second plant manager, Larry, who learned TPS/Lean from Toyota… at NUMMI. He was good, for sure.

So, I understand the comparison and the contrasts.

Quality Transformation: The NUMMI Miracle

Upon returning to California, the newly trained leaders implemented what they had learned. In just one year, the plant's quality soared to the same level as Toyota's renowned Takaoka plant in Japan. The very same workers who had been considered part of GM's problem were now producing some of the best cars in North America.

“The same people who used to work at the Fremont plant at GM plant came over. After three weeks, they came back and started manufacturing the same size of car, and quality became the highest one,” Mr. Yoshino said.

“So what makes that change? It's because of the transformation. Because the mindset of the workers who were sent to Japan.”

What changed? According to Mr. Yoshino, the key was mindset. Given the opportunity to work in an environment of mutual respect and shared goals, employees embraced a new way of working–voluntarily. As Mr. Yoshino put it, “We did not do anything else. We just offered the opportunity for them to learn, and they voluntarily decided to change themselves.”

I'd say that the change in worker mindset was the result of working for leaders who had a very different mindset.

The Role of Managers and Reinforcement of Learning

So yes, NUMMI's cultural transformation wasn't limited to frontline workers. Managers also had to adapt. While frontline leaders spent three weeks in Japan, managers from departments like purchasing and finance had only one week–a missed opportunity, in Mr. Yoshino's view.

To compensate, Toyota embedded experienced Japanese managers as on-site mentors, working alongside their American counterparts to guide decision-making and reinforce Toyota's principles.

“So Toyota sent the same level of managers from Toyota Japan to Fremont, California, and they partnered,” Mr. Yoshino explained.

“For example, an American purchasing department manager was partnered with a Japanese manager. So they worked together, cross by, you know, side by side. They had a desk, and whenever they made decisions, the American manager made some decisions, then his partner, a Japanese guy, we called it ‘coordinator,' worked together to finalize.”

Additionally, after the initial training, Toyota sent another wave of Japanese trainers to NUMMI for three months to help reinforce the learning. This reinforcement was crucial in sustaining the transformation. Within a year, the plant was not just functioning but thriving.

No Negative Feedback, Only Enthusiasm for Learning

There were perceptions outside of NUMMI–especially in Detroit–that Toyota's success was due to external factors like currency exchange rates rather than superior management practices. However, Mr. Yoshino never heard such sentiments from those who worked at NUMMI.

“I never heard anything negative about Toyota style,” Mr. Yoshino said. “Of course, they are not so much happy with salary level, but it's not Toyota or relation but it's NUMMI's choice. But from the mentality point of view, from the satisfaction or the relation between management and the workers level, all of them just keep saying that it was a great, great experience.”

He added that many workers were inspired by what they saw at Toyota's Takaoka plant and were eager to apply what they had learned back in California.

“They determined to take some of the things and put it to practice in Fremont, California. Not all of them. So when you put everything together, then that creates a huge change as a big group.”

Lessons for Continuous Improvement

The NUMMI story offers timeless lessons about leadership and change:

- Mindset Shifts Enable Transformation – “What we think is almost impossible can be changed to possible. If we become serious, we prepare something, and we're just ready to do something determined, then the impossible thing will change to possible.”

- Training Alone Isn't Enough – Reinforcement, mentorship, and hands-on guidance are necessary to sustain learning.

- Respect for People is Key – “They are not forced to [change], but they voluntarily decided to change themselves.”

- Impossible Can Become Possible – “People can change. We can change ourselves if we are ready, and we are determined, or if we run into a certain good timing and situation and arrangement.”

Mr. Yoshino's reflections remind us that change isn't about forcing people into compliance; it's about engaging them in a better way of working. The success of NUMMI wasn't a miracle–it was a testament to the power of leadership, learning, and respect for people. And it's an illustration of the power of a different style of leadership and a different management system.

What lessons from NUMMI resonate with you? Have you lived through a similar transformation? Share your thoughts in the comments below!

And I'll add that spending time with Mr. Yoshino was certainly one of the unique benefits and highlights of Katie's tour!

Related Posts and Podcasts:

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation: