You might still associate the “old GE” with Six Sigma, but under the leadership of CEO Larry Culp, the last five years, it's all about Lean. You can get a strong sense of that in the recording of their 2024 GE Aerospace Investor Day event (registration required).

First off, the old conglomerate General Electric has been almost completed dismantled. GE Healthcare was spun off last year, and the GE Vernova business will be spun off April 2nd. That leaves the GE ticker symbol as “GE Aerospace.” General Electric is no more (almost).

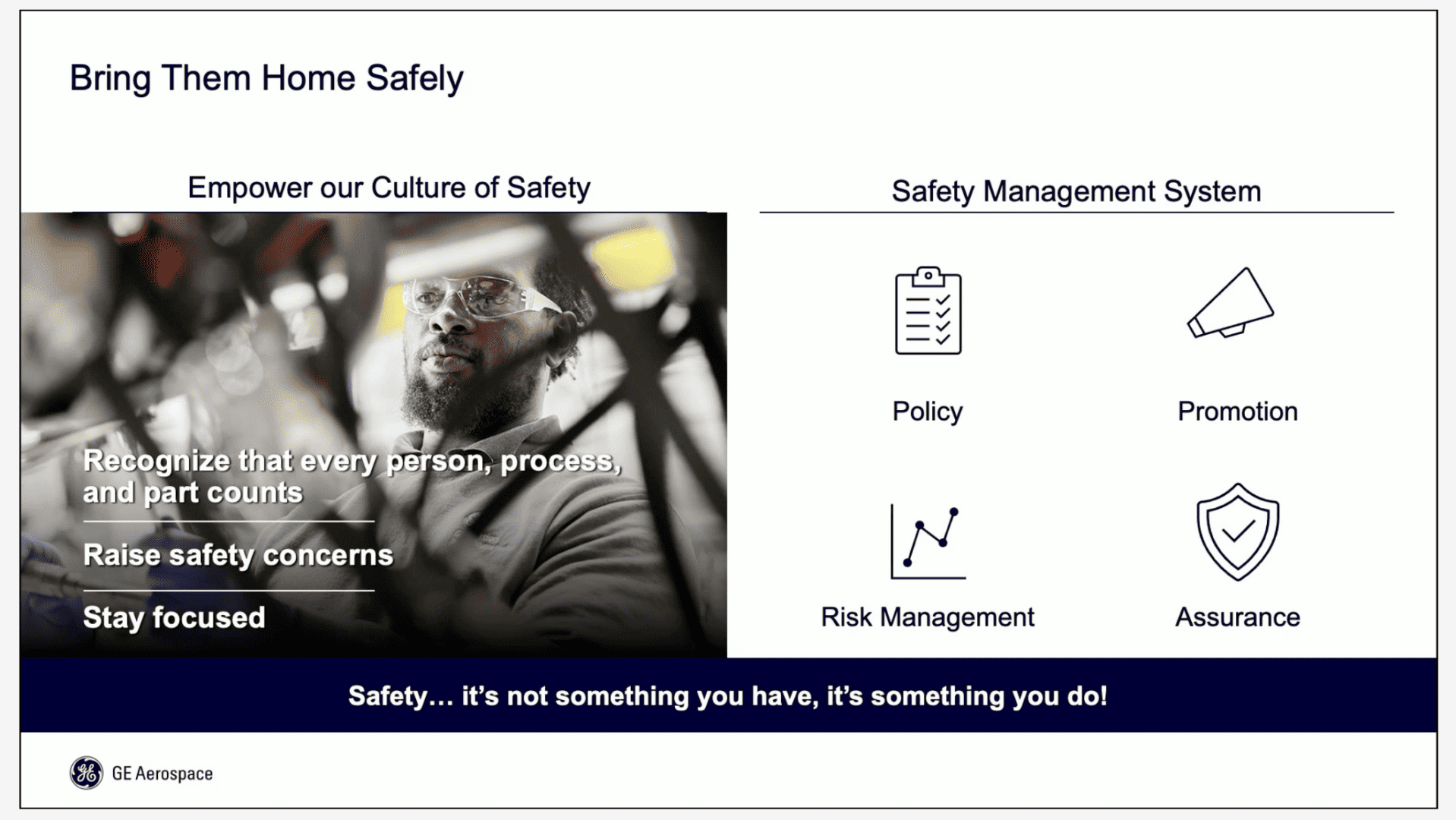

Kicking Off with Safety

As GE does with these events (such as the GE Lean Mindset event last year) and internal meetings, they always start with safety.

Steve Winoker, Chief Investment Relations Officer & VP, started (after a quick hello and legal/regulatory language about forward-looking statements) with a safety briefing for attendees (the investor/analyst community).

“At GE Aerospace, safety is our top priority. You often hear us talk about Safety, Quality, Delivery, Cost–in that order…”

So, he pointed to where the two exits were in the event of a fire or an emergency before handing off to CEO Larry Culp.

CEO Larry Culp's Remarks

After a very brief mention of the upcoming spin, Larry continued “on the safety theme” right away–a reminder about their purpose, which includes “bring them home safely” (those flying on planes or helicopters with their engines and their employees). It seems “lift people up” would have a double meeting for customers and employees, as well.

Larry talked about their responsibility for the roughly 900,000 people at any given time who are on GE-powered aircraft. Wow. And that's about three billion passengers a year. “That is an incredible responsibility” that all GE leaders and employees carry, “which is why we take safety so seriously.”

Larry emphasized, “our Lean mantra of SQDC that has really been at the heart of the Lean transformation of GE, let alone GE Aerospace.”

“Safety and Quality before Delivery and Cost. Easy to say. Hard to do.”

He added:

“It really comes back to respect for people, one of the most important tenets of any Lean transformation.”

Larry then threw to a video with one of their engineering leaders, Jonathan Blank, talking about product safety.

Engineering Leader Jonathan Blank on Product Safety

“We do not compromise on safety,” he says early in the video. “It is our purpose. Our employees, every day, understand this purpose… understand this is our number one priority. We continue to invest in our people, our processes, our systems, and our technology.”

Jonathan talked about their Safety Management System (SMS), which was introduced voluntarily in 2013, and was certified by the FAA (in 2017).

Every person counts… the encouragement to “raise safety concerns” must be backed by action. This framework “creates a culture of open reporting, where every employee is expected to raise a concern that they see or find anywhere.”

Here's the action: the commitment that “we will address it with a cross-functional team.”

GE Aerospace “created an independent office for flight safety and for engineering–not connected to the product line profit and loss center. We continue to learn and continue to grow in our understanding, because safety is a continuous improvement journey… it's a reflection of our learning culture and our Lean mindset.”

“We learn from every event that occurs.”

That's great to hear and that's what every organization (in aviation, healthcare, or elsewhere) should aspire to.

As CEO, Larry came back to emphasize that “the Flight Safety Office comes up through our Chief Engineers, as opposed to the P&Ls. We like that separation of duties… and a mandate to keep safety front and center.” The safety policy begins with “senior management commitment to improve safety” and promotion includes “create a positive safety culture in a workplace.”

The combination of their SMS, their Quality Management System, and their “Lean Operating System” is the “best way we know to operationalize flight safety at GE Aerospace,” says Larry.

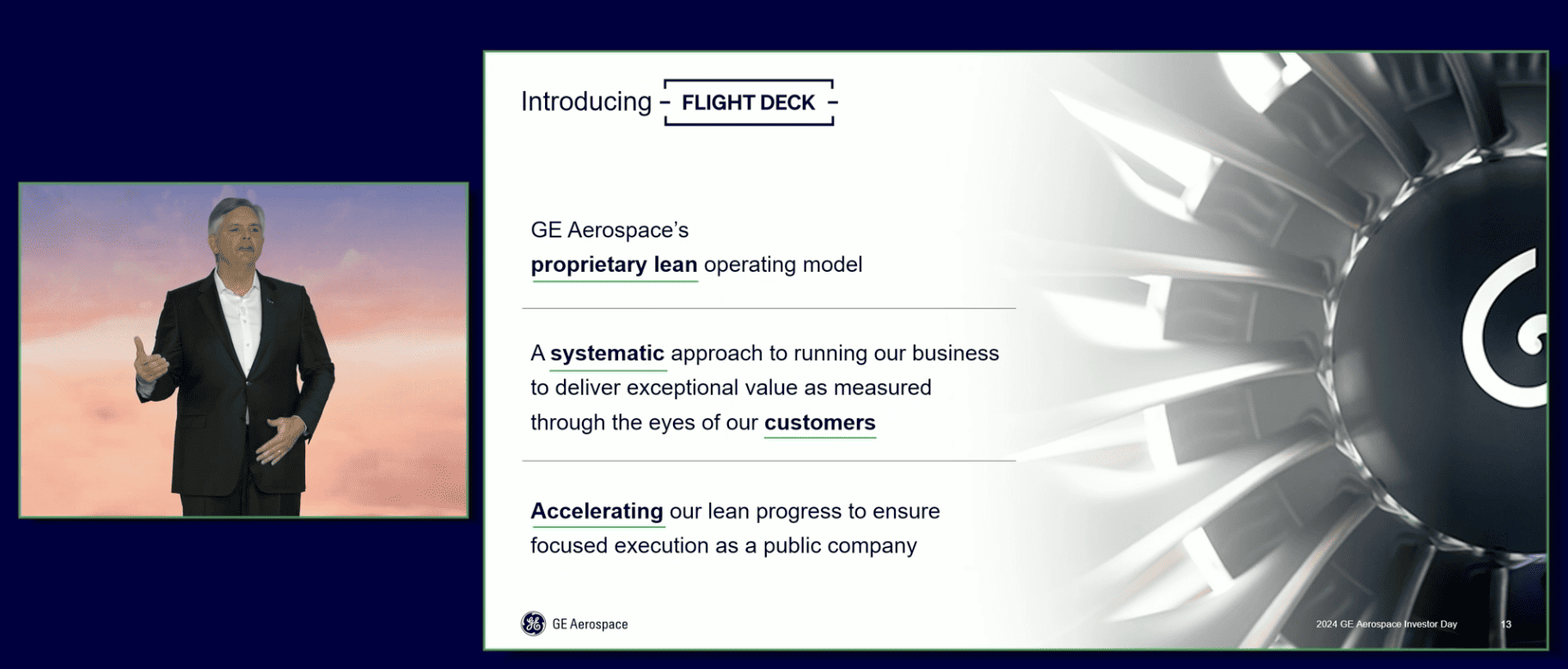

What is “Flight Deck”?

How will GE Aerospace implement their strategy? Larry says it's “Flight Deck,” the relatively newly rolled out name for their “proprietary Lean operating system.”

As it says on the slide, it's “a systematic approach to running our business to deliver exceptional value as measured through the eyes of our customers.” Larry said:

“It's the framing of the next step of our Lean transformation… this is the way we're going to run the business. We're going to run the business with the customers' expectations front and center… to accelerate the Lean transformation that has been building momentum.”

Here's video of that part of Investor Day:

Larry said, “Don't take it from me,” and threw to a video with some employees from around the world talking about Flight Deck.

It's rooted in “our leadership behaviors of humility, transparency, and focus.”

Of course, humility is a word that Toyota uses quite often. Flight Deck is their “bridge from strategy to results… operating as one team and with one strategy… Flight Deck is how we work, how we lead, how we soar.”

Back to Larry, he says that Lean “is not a means unto itself… it's a means to an end.”

Larry added, “Think about the way we run the business, first and foremost operationally, from an SQDC perspective, the financials obviously matter, but all the while we want to make sure we are also playing the long game. And that's where Hoshin Kanri comes in, that's the piece of the operating model that allows us to identify, through our strat[egy] planning process, the breakthroughs that we need to strengthen our competitive advantage and then operationalize them… to not only TALK strategy, but to DELIVER it.”

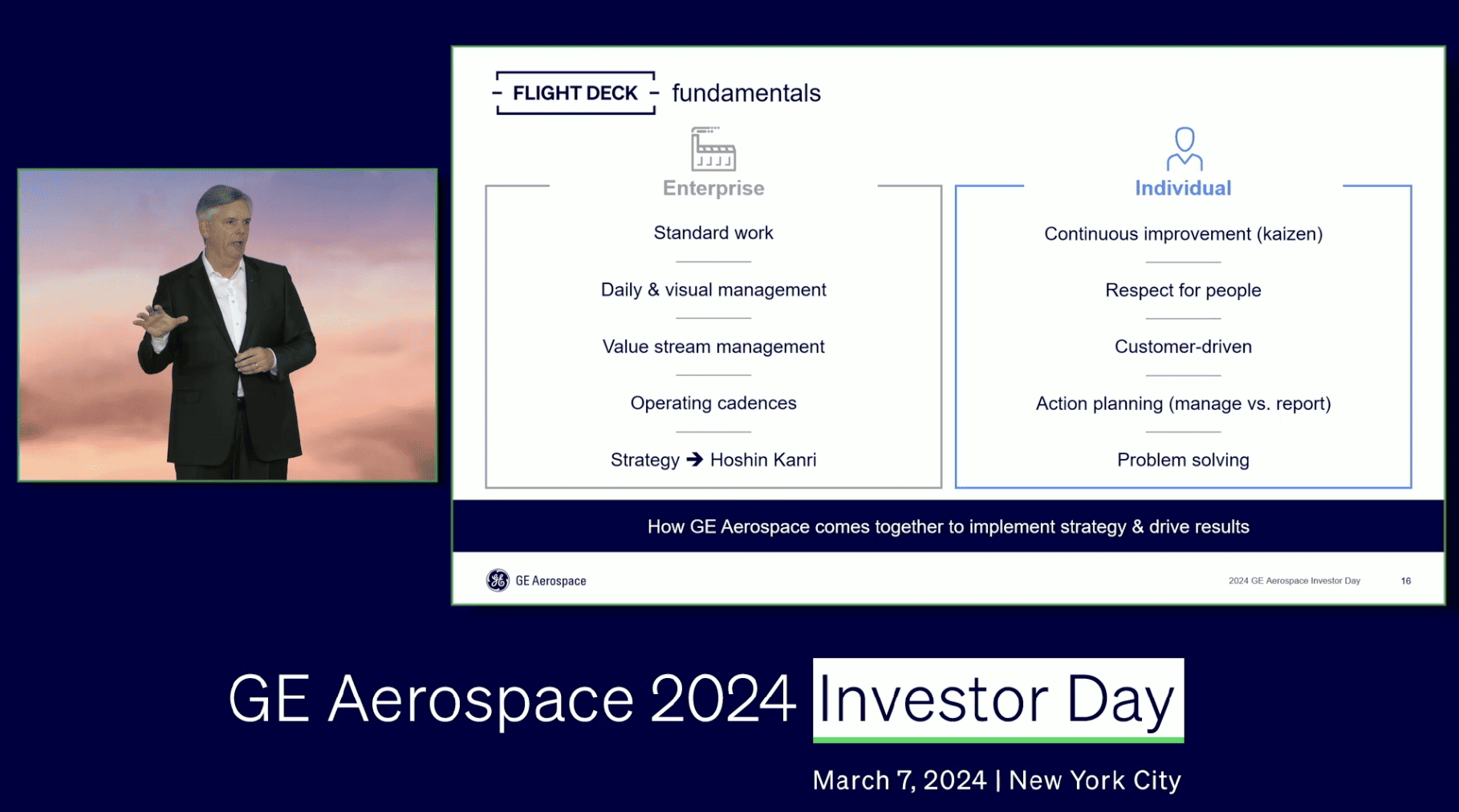

10 Flight Deck Fundamentals

Larry said he “could talk about this all day” (and I believe him!), but he wrapped up by sharing ten “Flight Deck Fundamentals.” You can see them below:

Enterprise:

- Standard work (“in contrast to quarter-end heroics”)

- Daily & visual management (“allows us to manage in real time”)

- Value stream management (“allows us to look at the work we do, not the functions that might be the way we're organized”)

- Operating cadences (weekly and monthly operating reviews)

- Strategy –> Hoshin Kanri

Individual (Expectations for Every GE Leader Around the World)

- Continuous improvement (kaizen) – (“we want everyone to have a continuous improvement mindset. We never rest.”)

- Respect for people (“and it starts with listening, maybe a little more than speaking”)

- Customer-driven (“really seeing us the way customers see us, not the way we see ourselves or would like to be seen”)

- Action planning (manage vs. report)

- Problem-solving:

“We want to be good disciplined scientific problem solvers, not casual finger pointers.”

I hope you find this all as inspiring and informative as I do. How could, for example, your healthcare system benefit from these mindsets and approaches, with a CEO who is not just sponsoring… but is actively driving Lean transformation?

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation: