The GE Lean Mindset event back in September was such an exciting day. One of my highlights was not just eating food prepared by Chef Wolfgang Puck's team — but meeting the man himself!

Later that day, Puck was on stage to have a fireside chat with filmmaker David Geld, director and producer of films like “Jiro Dreams of Sushi” and series like “Chef's Table.” I absolutely adore “Jiro,” as I blogged about here.

The recording is available on YouTube, thanks to GE, but I want to share some other stories and reflections from meeting and seeing Puck in this post:

- The setup, prep, and process for breakfast, as prepared by Puck's team

- What Puck had to say about customer focus and Kaizen (continuous improvement

Video of Geld and Puck:

Puck, the Life-Long Learner

Puck shared that, when growing up in Austria, he left home and quit school to start working in restaurants at the age of 14.

So how did Puck get to meet GE CEO Larry Culp? Puck, even with his global restaurant business success, was driven to take executive education classes at Harvard Business School. Larry was teaching at HBS, after retiring from Danaher (where he was also CEO) and before joining GE as their first-ever outsider CEO.

I was even more impressed toward the end of the day when I saw Puck carrying a few of the Lean books that GE was giving away to attendees. Puck was carrying, in particular, the book Leading the Lean Enterprise Transformation by George Koenigsaecker — a pretty hardcore Lean manufacturing book.

I wasn't able to catch Puck but I gave a copy of my book The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation to Chef Eric Klein, the VP in charge of Puck's catering operations. I did this when I saw Klein looking at the bookshelf (and Klein had just picked up a copy of my book). See more about the books given away that day:

Breakfast — Food and Operations

Speaking of catering operations, I first met Chef Klein when he was slowly stirring a batch of slow-cooked French-style scrambled eggs — one of the ingredients for luxurious breakfast sandwiches that were being served.

First off, the sandwiches:

- Toasted brioche bun

- Soft scrambled egg

- Parmesan

- Chives

- Shaved black truffle

Wow. Click on any photo for a larger view.

Puck is known for innovating the “open kitchen” concept at Spago in 1982, so having a display kitchen for the event isn't a surprise.

Here's how the area looked the night before:

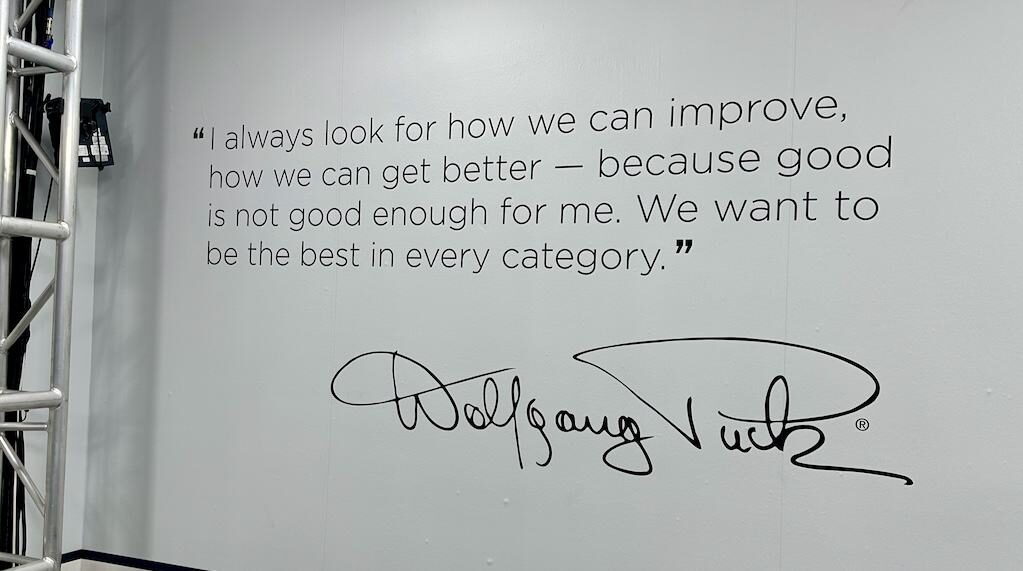

What's that say above Puck's signature? It seems to be a concept that's not just a slogan to him, zooming in:

Always looking to improve. You can see why Larry Culp and GE invited Puck to talk about continuous improvement, as he lives it (and probably breathes and eats it).

When Puck arrived, he immediately checked on the food and his team:

Meeting, greeting, and posing for photos could wait. I was thrilled to get to say hello and get a photo with him that morning. Puck was warm, friendly, and engaging. He wasn't being a celebrity big shot.

I didn't take notes, but I remember asking him about quality and how much he has to travel worldwide to oversee restaurants… overseas. Puck said something about having a great team, but he still felt the need to go and check in — which seemed more like being a “coach” than a “boss.” That was my impression from seeing him interact with his team.

During the formal session, Puck made clear that success was “not about me. It's because I have a great team!” He was proud that so many of them have worked for him for a very long time — and that longevity and stability is the “key to success.”

Before I write more about the video, I'll share more about the breakfast setup.

The night before, standard locations had been planned out for everything on the acai bowl bar:

And here's how it looked the next day:

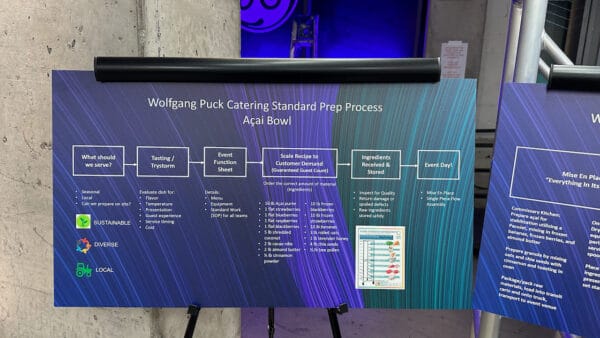

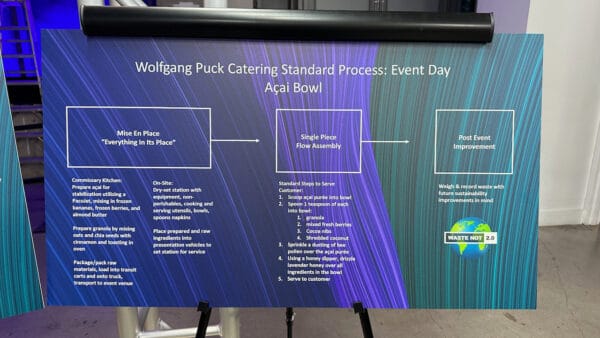

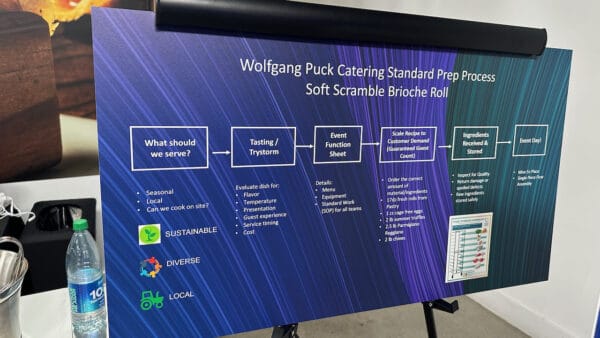

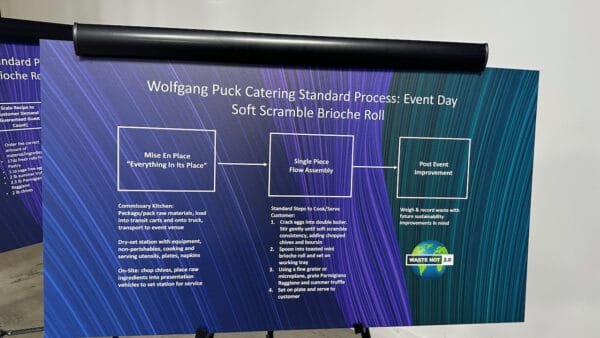

The process focus was apparent as boards were displayed showing the standard process for the egg sandwiches and the acai bowls (click either photo for a larger view) — the “prep process” and “event day” standard process. First, the acai bowls:

Then, for the “soft scramble brioche rolls”:

The prep process is sort of like an end-to-end product development process:

- What should we serve? (including “can we cook it on site?”)

- Tasting / trystorm (evaluation of the food and guest experience)

- Event function sheet (including “standard work for all teams”)

- Scale recipe to customer demand (including ingredients and quantities to order)

- Ingredients received and stored (and inspected for quality)

- Event day! (including “mise en place” set up, which is like “5S,” and “single piece flow assembly”)

The acai bowls were certainly made in “single piece flow” — based on the ingredients that were staged in bowls that we might call a “supermarket” to pull from.

The egg sandwiches were being made in small batches. As I mentioned, the scrambled egg cooking was designed here as a batch process. In theory, one could scramble one egg at a time. But, from my experience cooking a small batch (two eggs) at home, it's difficult to get that soft-cooked, creamy, almost custard-like consistency with a small batch. And the egg cooking is more time-consuming than the next steps. Puck and team probably didn't want to make people wait for “their” eggs to be cooked.

The next steps could have been in a truer single-piece flow — the toasting of the buns, the filling of them, and the topping of them. But they were being moved along in small batches of, as I recall it, four or six pieces. I'm not criticizing — just sharing my observation that it wasn't literally single-piece flow. And, as I was taught, one-piece flow is a goal and a direction to work toward — it's not something to be overly dogmatic about.

What mattered here was that the sandwiches were delicious and, even when it got busy, they could keep up with demand.

For lunch, we had pre-made bento boxes, which were also amazing (no picture, sorry).

David Geld and Wolfgang Puck in Conversation

It was a fascinating discussion between two food lovers. Here are a few highlights from the session.

Food Quality and People Development

In elaborating on his team and their longevity being the key to his success, Puck added, “My process is… how do I select the people who work with me, how do I keep them with me, and how I see them grow. Because growth in a person is the most important part to me.”

That mirrors Toyota's emphasis on being a “people development” company.

“The people who work with me are the most treasured asset, really.”

Puck said, “Anything cheap doesn't mean anything if it's not good.” His team isn't pressured to hit a food cost percentage metric to earn a bonus. That said, Puck later talked about the slim margins in the restaurant business and how they do look at cost figures, compared to budget categories, to see where they need to improve.

He tells the chefs in his restaurants to “buy the best ingredients and don't F them up.” Some lessons we can apply at home include not ruining the flavor of the world's best tomatoes by refrigerating them for three days, as Puck said.

As in any business, Puck says execution is very important. “So we have to train people from the bottom up” so young people who are new to the industry can keep moving up to a role like chef or manager within his company.

On Failure and Mistakes

“I don't want to punish somebody for failure. I punish somebody if they're lazy or don't work.”

I love hearing a leader say they won't punish somebody for failing. Punishment only ensures that people will get better at hiding mistakes or failures instead of learning and improving — as I wrote about in The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation.

Later, he added:

“I don't mind if somebody makes a mistake. I don't mind if something is a failure… as long as they won't do it again. To me, that helps everybody to be more inventive, to take more chances, to take more risks.”

Geld added that, as a filmmaker, it was a challenge to shift from leading a small team (“Jiro Dreams of Sushi”) to empowering many teams that are creating the many “Chef's Table” series for him at Netflix.

Geld said, “…and learning to trust them in the space to take swings… it's OK if they're going to fail because we'll be there to help them get back on track.” I love it.

On Customer Focus

Puck discussed the need to focus on different customers in different parts of world — as their dietary restrictions and preferences vary. He can't serve a steak cooked medium-rare in some cultures, for example. It's a good reminder to focus on each unique customer instead of “the customer” broadly.

Just as important as the food is the way his restaurants make the customers feel. They all aim to be “guest centric,” which reminds me of Toyota's passion for the customer. Puck has also worked hard to break down silos — between the kitchen and the dining room — so they aren't just getting along but focused deeply on meeting the customers' needs.

Puck told a story about how, long ago, he would refuse to cook a steak well done for a customer (even if it was the famous actor Paul Newman). Nowadays, even if that's not how Puck would prefer to eat a steak, he'll do that if the customer wants — thinking as the business owner, not just as a chef.

On Kaizen

Geld asked Puck about his mindset of, like Jiro, constantly trying to improve.

First, Geld admitted he hadn't heard the term “Lean” before Culp invited them to the event. But he recalled how Jiro worked every single day to master something. Again, Puck says he learned about that word from Culp. “We learned about Danaher.”

“For me, it was always about continuous improvement. I didn't know the word kaizen but, in my head, it was how are we going to get better every day? How can we do things better? How can we store things better? How can we involve the farmers out there to give them a better living?”

Puck also values long-term relationships with suppliers — farmers and purveyors — some of which he has also worked with for 40 years (and some of his restaurants have been open that long). That also reminds me of Toyota's approach to suppliers — partnering over time to find win-win relationships.

“Continuous improvement is the most important part [of his business].”

Puck also looks for new technologies that can be used to cook and serve food in innovative ways. We might use a different Japanese word, kaikaku, to talk about more “radical improvement.”

“The only way to move forward is continuous improvement and continuous innovation.”

But he adds that it's important, for his business, to “not forget about tradition” because customers expect a familiar dish to taste the way it did five years ago.

“For Kaizen, we're always thinking ‘How can we get better? How can we do things more efficiently… without really taking anything away from quality or from the guest experience.”

After watching a clip from “Jiro Dreams of Sushi,” Geld said that Jiro, as a chef, strives for perfection even though that's something he can never attain. He asked Puck what he strives for… “We all strive to get better.”

Let's all keep doing the same! I appreciate the insights and inspiration that were shared by Geld, Puck, and everybody at the GE Lean Mindset event!

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

[…] be sure to check out Mark Graban’s article highlighting the Wolfgang Puck’s team putting together the food at the […]