Scroll down for how to subscribe, transcript, and more

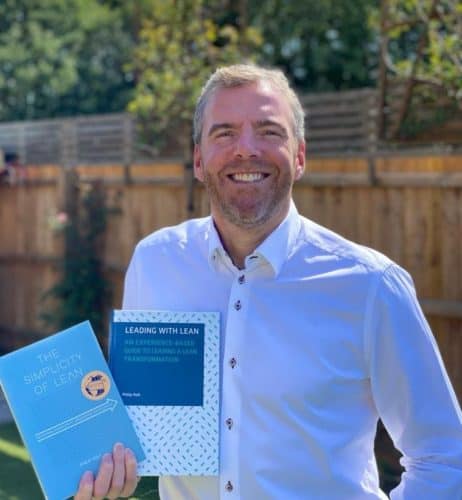

My guest for Episode #460 of the Lean Blog Interviews Podcast is Philip Holt.

He is currently Senior Vice President, Operational Excellence at GKN Aerospace, the world's leading multi-technology Tier 1 Aerospace supplier, and has over 30 years of business experience in leadership roles spanning the customer value chain, in industry-leading Companies also including Philips, Gillette, and Travelport.

He is the author of three Lean Leadership books:

- Leading with Lean: An Experience-based guide to Leading a Lean Transformation

- The Simplicity of Lean: Defeating Complexity; Delivering Excellence

- Leading Lean by Living Lean: Changing how you Lead, not who you are

Learn more at his website, www.lean-master.com.

How does Philip define Lean simply and succinctly?

!["[Lean is] about giving everybody in the organization the opportunity to do their best every day and to feel completely engaged and fulfilled by the work that they do." - Philip Holt](https://www.leanblog.org/wp-content/uploads/2022/10/Lean-Blog-Podcast-Quotes-500x500.jpg)

Today, we discuss topics and questions including:

- Your “Lean origin story?”

- “Thought I knew what Lean was”

- How did visiting Japan help?

- Kaikaku — breakthrough improvement vs. continuous improvement

- Dunning-Kruger Syndrome (and “Mt. Stupid“)

- Systemic view of Lean / TPS – can't grab just pieces

- True North?? How to define that?

- What are some of the ways in which people overcomplicate Lean?

- Overcomplicating problem solving? Six Sigma… A3?

- Start at the most simple form of problem solving

- How do you describe Lean simply?

- How do you define “transformation”? When it's fully aligned with the strategy of the company…

- What “transformational results” would you expect to see?

- Zero Accidents goal – the Heinrich Triangle

- Unlearning the old way so we can lead in a Lean way?

- BTFA – Believe Think Feel and Act

- The personal benefits of Lean at work and life??

- What is a “life in balance”?? What does that mean to you?

- Using lean tools at home?

- Push vs. pull for information??

The podcast is sponsored by Stiles Associates, now in their 30th year of business. They are the go-to Lean recruiting firm serving the manufacturing, private equity, and healthcare industries. Learn more.

This podcast is part of the #LeanCommunicators network.

Video of the Episode:

Thanks for listening or watching!

This podcast is part of the Lean Communicators network — check it out!

Automated Transcript (Not Guaranteed to be Defect Free)

Announcer (1s):

Welcome to the Lean Blog podcast. Visit our website at www.leanblog.org. Now, here's your host, Mark Graban.

Mark Graban (13s):

Hi, it's Mark Graban here. Welcome to episode 460 of the podcast. It's October 12th, 2022. My guest today is Philip Holt. He is the author of three books. You'll learn more about them and him in a minute. And through the episode, those books are titled, Leading With Lean, The Simplicity of Lean and Leading, and Lean By Living Lean. So if you wanna learn more about Philip and his books, you can go to lean blog.org/four 60 is always, Thanks for listening. Well, hi everybody. Welcome back to the podcast. I guess today is Philip Holt. He is currently a Senior Vice President of Operational Excellence at GKN Aerospace, which is the world's leading multi-technology tier-one aerospace supplier.

Mark Graban (60s):

And Philip has more than 30 years of business experience in different leadership roles spanning the customer value chain. He's been in other industry-leading companies, including Phillips, Gillette and Travelport. Philip studied at Manchester Metropolitan University, Warwick Business School, and the University of Pennsylvania Wharton School. So he's a regular speaker at Lean Six Sigma and Operational Excellence conferences. So before I tell you a little bit more, and before I tell you about his books, it'll form kind of the basis for our conversation today. First off, Philip, welcome to the podcast. How are you?

Philip Holt (1m 35s):

I'm very well, thank you, Mark. And thanks for having me on. Its, it's a pleasure to be here.

Mark Graban (1m 40s):

Well, I, I'm, I'm glad we can talk and, and I've already alluded to the UK and people can tell where, but I'll, I'll ask where are you located these days?

Philip Holt (1m 49s):

So, I'm located in a, a small market town called Bury St Edmonds. It's just to the east of Cambridge, which listeners are probably more familiar with. But my, my accent betrays the fact that I'm actually from the north of England originally. So I'm from the Manchester area, but it's an accent that's followed me around wherever I've lived.

Mark Graban (2m 8s):

Yeah, well it's, when I, when I've worked in the, in the UK, I always thought, boy, things sound smarter in a British accent. They, they, they may have been just teasing me when they claimed maybe the opposite was also true. There's something about not being a prophet in your own land, perhaps, but that's, that's a different story.

Philip Holt (2m 28s):

Absolutely.

Mark Graban (2m 30s):

But, so Philip, Philip pt, again, his website is lean-master.com. I'll make sure there's a link to that in the show notes. And I'll put a link to his three lean leadership books. So the first book was titled, Leading with Lean, an Experience-Based Guide to Leading a Lean Transformation. Sorry for the defect there, Philip. The second book was The Simplicity of Lean Defeating Complexity, Delivering Excellence. And the third book is Leading Lean by Living. Lean, Changing How You Lead Not Who you Are. Did, did I have a typo there? Is that a different defect?

Mark Graban (3m 10s):

Is it cha changing How No Change? I said it wrong again. My goodness. Changing how you Lean. This is okay.

Philip Holt (3m 18s):

It's actually changing how you lead, not who you

Mark Graban (3m 21s):

Are. That's the typo. My goodness. I am full of defects and mistakes and I did not do it right the first time. But in the spirit of leading a lean life, which we're gonna come back and talk to, I'm, I'm gonna not edit out those mistakes that we're, we're all human. And that's a part of being a lean leader, I guess, is recognizing that.

Philip Holt (3m 45s):

Absolutely.

Mark Graban (3m 47s):

So we'll, we'll get to take a deeper dive into all of that. I will quit stumbling through my attempts to read things here. But you know, Philip, before we talk about the books and, and, and you know, the things you've learned along the way, how, how did your Lean Journey, if you will, you know, start off? I, I I like asking guests. I think it's always interesting to hear the origin story for you. Kind how the, where the, when did you exposed

Philip Holt (4m 16s):

Yeah, Part always described was the part where I thought I knew what Lean was. And the second part was when I realized I didn't and started to learn it again. So the, the first part was when I think like a lot of people, I was, I was running operations in a company. One of my first companies I worked for, I started to, to pick up books. I read The Machine that Changed the World looking at Total Quality Management, you know, all the good stuff of the late eighties and nineties. And, and started to use the toolkit I, I got during the nineties of Six Sigma Green Belts as well and, and felt that I had a really good grasp of the Lean and the Six Sigma toolkit and run some, some projects where we had, you know, significant results and people were happy, senior leadership was happy.

Philip Holt (5m 9s):

But one thing that started to dawn on me on reflection was that there was a lot of deterioration after the fact. And, and also it was very difficult to see the overall improvement in the overall value chain. And, and I didn't really realize why that was until in 2008 I joined what we called the Simply Phillips Lean Operating Model in, in Phillips. It was essentially a reboot of the, the Lean program using a a five-phase lean operating deployment model. And we, I was fortunate enough, we went over to Japan for two weeks to do what we called the Kaikaku experience, a best practice experience.

Philip Holt (5m 52s):

And it was, whilst I was out there, it really started to dawn on me that I'd completely missed what Lean was all about, what Lean leadership was all about. And it came clear to me that, you know, the tools are exactly as we call them, the tools. And it's not about the tools. The tools are relatively straightforward. You get some more complex tools, you know, if you think of Theory of Constraints and some of the, the higher end Six Sigma problem solving, of course you need real true experts to, to solve that. But most of the tools are pretty straightforward. What really matters is the leadership part of it. How you really understand what makes an organization tick and how you get everyone in the organization rallying around that.

Philip Holt (6m 35s):

So since about 2008, I've been relearning what Lean Went and I, I would guess I was on what, what sometimes called Mt Stupid on the Dunning-Kruger experience and confidence level or expertise and confidence level. And I, I think I quickly crashed down stupid in 2008 and realized that I didn't know a lot of what I didn't know and, and started to learn ever since. And that's, that's been my second part of my, my journey.

Mark Graban (7m 4s):

Yeah. And yeah, I mean I, I I, I'm pic that diagram and maybe a lot of our listeners can as well about Dunning Kruger syndrome. But yeah, that, that, that, that label of Mt. Stupid, I mean there's clearly a difference between stupid and ignorant. I mean, it's, it's, it's almost more Mt. Ignorance. We don't know what we don't know. And that I, I appreciate you sharing that, Philip. Cause I think that's a part, if we're being honest about it, all of our lean journeys to some extent of relearning or learning better or having better coaches, better influences. So, you know, I appreciate you, you know, being willing to talk through that.

Mark Graban (7m 49s):

You know, kaikaku is an interesting word. I dunno how it was taught to you, but more like radical improvement as opposed to kan or more incremental improvement, Right?

Philip Holt (7m 59s):

Yeah, AB absolutely, and I, I talk about this in, in all three of my books actually, Mark, because there's, I mean, there's all often a common misconception that continuous improvement is just about kaikakku, I think often people actually use them as synonym continuous improvement. And kan is, is the same thing. And, and that breakthrough improvement is something separate. And, and I I, I really try and disabuse people of that and, and say, look, continuous improvement is exactly what it says on the 10th. It's continuous improvement. And whether that improvement is incremental or radical breakthrough improvement, you actually need both.

Philip Holt (8m 41s):

And that's why a really successful organization has both that hoshin / policy deployment approach to making breakthroughs and also tries to build that army of problem solvers who are every day doing those incremental changes. Yeah,

Mark Graban (8m 56s):

Yeah. I I, I totally agree with you. And you know, there, there are a lot of organizations while, you know, we're, we're, we're talking about mistakes, maybe, you know, organizations that only, that make the mistake of only wanting large project projects that only have large roi. And like, okay, there's, there's a time and a place for that. But they miss out on, you know, I I, I like the Toyota diagram, the Toyota Way field book is where I first saw it of like, you know, three levels of kaizen, large rocks, smaller rocks, and tiny pebbles. You know, a lot of people make the mistake of not doing any of the daily continuous improvement kind of kaizen or people only do the middle level, you know, which is maybe the kaizen events.

Mark Graban (9m 38s):

You know, I'm, I'm, I'm curious what other reflections you have from seeing different places or different leaders only using parts of the improvement approach.

Philip Holt (9m 49s):

Yeah, AB absolutely. I I think that's, that's pretty, pretty common, pretty standard across most companies. It's kind of a, I think, I think lean leadership or lean is often seen as kind of a pick and mix. And, and it, it doesn't work like that. It, it's really a holistic model of leadership that, that needs to be a choice. And, and you need to be all in. I, you know, I often use sporting, you know, analogies or metaphors and, you know, I say it's, it's like choosing a fitness regime, but deciding, well, okay, I'm going to, I'm gonna go out running, but I'm still gonna drink beer every night and, and eat pizza.

Philip Holt (10m 30s):

You know, it's, you've got, you've got to decide are you in or are you, you can't be kind of half into this. And, you know, so, so what, what we've tried to do, and I did this in my previous companies as well, is we, we create what we call the opportunity corridor impact and, and difficulty and, and, you know, the low impact, but low difficulty are the kaizen And you want many of those, you want to create this as I call it an army of problem solvers who are everyday able to solve the problems that they encounter daily. Then you've got this kind of middle group and there's kaizen events, the ones where you get teams together and they try and solve some of the bigger rocks, the larger rocks.

Philip Holt (11m 13s):

And then you've got the, the few really significant breakthrough projects. And those can be, you know, technology breakthroughs, investments design, or they could be a Six Sigma or design for Six Sigma type of activity. And you've got to do it all. It's got to all happen to really be a successful company. Yeah.

Mark Graban (11m 33s):

There's, there's all those layers, but then those larger breakthrough improvements that, that require time and investment, that it seems like that's where you need to prioritize. I, I, I, I try to encourage people when it comes to the small kaizen improvements that really don't require any spending or, or much time that, that it might be waste to prioritize the little ones, but the big ones that we don't have unlimited time or attention or, or, or money. Right. So I, I'm wondering if you could elaborate a little bit more on this idea of how to prioritize those based on, you know, organizational need.

Philip Holt (12m 12s):

Yeah, I'm, I'm a great exponent of, of H can. Yeah. I mean obviously it was developed by a, a, a, you know, companies many years ago, Toyota, again, are famous for that. Danaher actually is probably one of the most successful at using this in the, let's say in the west. They've, they've been, you know, almost ruthless in their use of portion to prioritize and really grow the, their businesses. And, and to me it's, it's a great tool. Again, it's a tool. The leadership needs to come around that to actually make it successful. Too many times I walk into businesses, locations, manufacturing sites where they, they talk about having a hoshin.

Philip Holt (12m 56s):

You look at it and they've got 20 things on there where you've not got a hoshin, you've got a shopping list of, or a wishlist. Yeah. So it's really about that ruthless prioritization and decision and, and choices. And I often say to people, you know, they say, Well, if we only do three things, you know, what if we do them all and we've got time to do other stuff? And I say, Fantastic. That's a how many companies end the year say we could have done more. Yeah. The vast majority of organizations end the year having failed to do most of what they really wanted to do if they're honest with themselves. Yeah.

Mark Graban (13m 30s):

Yeah. Being honest about your organizational capacity I think is really important. And I've seen, you know, I've seen organizations in healthcare apply this really well of instead, you know, looking at these big initiatives that all have their argument for why they should be done. It's not just yes, no, there's this third bucket of well, there's, yes, there's no in between. There's yes, but not now, Right. That it's better to get a couple things done and then move on instead of like this organizational, you know, swirl or you know, where, where people point fingers and say, Well, I didn't get that project done because I was pulled into this one. And somehow vice versa. Or if you have too many projects all requiring, you know, it, well now you, you've, you've outreached the capacity of that part of the organization.

Mark Graban (14m 19s):

These, these are the things that we have to talk through. Right?

Philip Holt (14m 22s):

Yeah. AB absolutely. But again, it comes back to, it's, it's, it's all about, like, everything in, in lean leadership. It's about the leadership and it's about people. And it's taking the politics out of this, you know, get getting everybody together and really doing that work. I mean, in, in GKN Aerospace, we started our hoshin, you know, a month or so ago. We're, we're working busily on it now. And the idea is that every single site across our, a state of 38 sites by the end of this year have got fully aligned portion goals that are hand shook with the business line president and coo, and they know exactly what they need to deliver with really those, those top three, hopefully top three, but certainly no more than five priorities to deliver next year.

Philip Holt (15m 10s):

But ones that sizeable and will make a real step change. But at the same time, back to our earlier discussion, you know, the, everybody is doing the in every day that culture of everyday improvements as well. So you get that combined power.

Mark Graban (15m 25s):

Yeah. So you talk about not having too many different goals and you know, there, there's the extension into not having too many high priority initiatives. How, how do you talk through or teach through people the concept of true North that stays more consistent. Like the goals this year might be different than the goals next year, but true North tends to be just that more, more consistent. How would you work through with an organization if, if they don't have a good articulation of true North?

Philip Holt (15m 57s):

So, so they need to, they need to determine what, you know, it's, we often, you often get these arguments about does lean work bottom up or top down? I'm a great believer it only really works if it's done from the top. So you've, you've got to have a, a ceo, you've got to have a leadership team for the organization that has articulated properly what the breakthroughs are that they expect from the organization over the coming years. And then you can determine that as a strategy deployment through h So again, the keeping is h isn't about the strategy, H is about how you deploy the strategy and make it executable and, and realize it.

Philip Holt (16m 41s):

So you've got to start with that. So again, a lot of work and we, we were fortunate to have a new CEO come in last year who's been very crystal clear on what his expectations are. And that pervades throughout the organization. Everybody knows what true office. So it's then about how are you going to achieve those, those results.

Mark Graban (17m 0s):

Yeah. And if an organization is struggling, it seems like there's one of two things that could be true. It could be the wrong strategy or the wrong strategic choices well executed or the right strategy and priorities poorly executed. Yeah. How, how, how would you kinda best diagnose a situation if it was one or the two or, or somehow both.

Philip Holt (17m 27s):

Yeah, so I think the easiest one to, to diagnose is the one where it's a, a strategy. Maybe we don't call it a bad strategy, but it's not the optimal strategy. It's being executed well, but it isn't getting the results that the business require that, that you can problem solve pretty easily. Because you can say, Hey, look, I don't know if you've ever seen it, but there's this two by two about results versus process. And in hoshin, we need both to be true. We need that top right hand box. So if you're getting basically a good process, the people doing the hoshins are coming out with the right kind of out output, but we're not getting the right results for the business, then something's wrong with what we're trying to achieve.

Philip Holt (18m 9s):

That's probably easily diagnosable in terms of, you know, it's the right strategy but not executed. I guess that becomes patently obvious. There's not even problem solving required. You can just see that it's not working. And, and again, if you're following your hoshin process, it should quickly and clearly become obvious if people aren't delivering because there's this monthly review cycle that should pick that up early. But again, it's, you know, I keep coming back, I sound like a little bit of a broken record, but it, it all comes back to leadership. If we don't have the right leadership throughout every level of the organization, it, it just won't work. Yeah.

Mark Graban (18m 49s):

So we're gonna come back and we certainly wanna talk more about leadership, so you know, of, of your three books, Philip, I actually want to talk about the second one first, if that's right with you. So the second, the second book is the simplicity of lean. What, what are some of the ways, So, you know, it seems like that book is a countermeasure to something and, and one of those problems might be different ways people maybe overcomplicate lean or overcomplicate some of those concepts. What, what, what are some of the most common over complications that, that you've seen or experienced?

Philip Holt (19m 26s):

Yeah, so I, I think the, the biggest over-complication, and again, I'll, I'll hold my hands red-handed here, I've done this myself, is to say, Look, I've got a hammer. So every problem is a nail. So you, you walk around, you know, I, I've mentioned hoshin kanri and I'm, I'm, I'm absolutely passionate about it, but I couldn't, I shouldn't just walk into an organization and say, Hey, hoshin kanri's great. So you need to know, do hoshin kanri. You know, the biggest, one of the biggest mistakes and one of the biggest overcomplications is to go in and do lean because we should do lean Now. What we need to do is we need to make the business better, the organization better.

Philip Holt (20m 6s):

We need to make it better for its people, the people who work there for its customers and for its shareholders. So we've got to make the organization better. The question is, what are the biggest problems the organization faces? So once you start to have those conversations, you shouldn't even be talking about Lean or Six Sigma or any kind of tool at this point. The discussion should really be about what do we want to solve as a business? Once you've kind of got that and you've socialized that, and certainly at the leadership level it's agreed, then you can start to talk about how are we going to, to do this? And that's when you can start to bring lean into the force.

Philip Holt (20m 47s):

So that, that's kind of the red thread through the simplicity of Lean is, is really about not putting the cart before the horse, you know, really understanding what is it the business needs first and then applying the right tools appropriately to, to solve that. And it really is, you know, like I say, red-handed here, I've done this myself where I've gone in and said, Hey, we've gotta go do lean and we've got this great plan and we've got this great program. And everyone says, Oh yeah, we've heard we've gotta do lean. But after a few months, people turn around and say, Well, why are we doing this? And you even see, you know, separate meetings for people to solve the real business problems while there's these meetings to go do this lean stuff. Oh gosh, sure.

Philip Holt (21m 27s):

You know, that's, that's, that's, that's the kind of terrible, and I guess you've seen this many times in healthcare as well.

Mark Graban (21m 33s):

I, I've, I've seen it in different settings even, you know, back to manufacturing days. But, you know, I love the way you emphasize that and I try to pass along lessons that I've learned in different ways, right? Cause you know, people will often reach out to me and they'll ask about tools. They're at that stage in their development or their journey. You might get asked this to Philip, but like, you know, what, what should we do first? What tool should we implement first? And I tried to steer it back to, you know, kind of drawing upon, I was point to Taiichi Ohno and his book on TPS. There's a chapter where the header says, Start from need, right? And then, you know, later on there, he makes a point about your most pressing needs, which is, you know, Exactly.

Mark Graban (22m 18s):

I mean that sounds like what I hear you saying. And then, you know, even back to John Shook when he was with the Lean Enterprise Institute, what problem are we trying to solve, you know, was a question he would always bring up. So, you know, it seems like it, it, if there there's an opportunity or a need to use this high level lean problem solving thought process of not jumping to solutions, making sure we understand and frame the problem well. I mean, I think that's, that's always a good reminder at, at the organizational level or at a much more detailed, you know, shop floor problem kind of situation.

Philip Holt (22m 55s):

Absolutely. Yeah. Yeah. Without,

Mark Graban (22m 58s):

Yeah. So focusing on, on why we're doing things and, you know, not over complicating. So one, one other thing I was gonna ask you about, cause I've, I've seen this in, in different settings, different ways organizations might overcomplicate problem solving for a certain situation. When I think of the last manufacturing company that I worked for, you know, I was going through a lean training and certification track and had a project where I was supposed to solve a business problem with lean methods. Well, you know, there's somebody next cubicle over who was going through a Six Sigma black belt track and, you know, and part of her certification was, was quite literally based on you need to use all of these tools and it was really slowing her down when it was not an inconsequential business problem that she was solving.

Mark Graban (23m 47s):

So I'm, I'm not criticizing Six Sigma, but I think it comes back to the question of like being situational. What, what have you learned about the, the, the, the right level of complexity of problem solving for the right type of problem? What, what have you seen?

Philip Holt (24m 3s):

Yeah, I think, I think the, the key thing here, Mark and I, I recognize exactly what you're talking about here. And the, the key thing for me is start at the bottom level of problem solving and escalate until you've solved it. So the, the first thing is kind of jdi, just do it. So the first thing is are we actually run into standard? So if we're not running to standard, just return to standard. So that's the first check. Cause I, I've seen far too many times problems being solved. What we're actually doing is reinventing the wheel because we're not running to standard. So it's made sure, first of all, we're running to standard and that's the first thing that we should teach in any good problem solving.

Philip Holt (24m 44s):

And the next thing is A3s. So we teach very simple A3s, concern cause countermeasure, and it's very deliberately not root cause because you want a lot of this going on every single day. So the first time something happens, if we get a concern up, people believe they know what cause is and they can put a counter measure in place to quickly try and solve, solve it, then that's good enough. Now, if it recurs, you might need to get into more complex problem solving. But the first thing is we want the first level so that tier one of level the operation team leader to be trying to solve these things quickly. And if you've not solved the problem level, then you can go to some practical problem solving some a three type of problem solving or ad depending on the industry and the approach you take.

Philip Holt (25m 34s):

But essentially, you know, a structured A3 of problem solving if you've ultimately can't solve it at that level. And generally that's when you can't really get to the root cause easily and you don't understand why you're getting variation or performance issues, then you might escalate it to a Six Sigma type of problem solving. But again, it's go through those escalation levels, don't just jump to one solution. And to your point about your colleague and, and back in the manufacturing company with a black belt, you know, I've seen that many times when again, it's about doing the project rather than solving the business problem. Yeah. And so what we've done with our Six Sigma training, both at the green belt and black belt level, we've really slimmed down the curriculum, the standard curriculum, and then the idea is that someone is solving a problem if they need tools we've not yet taught them, then they pulled those tools and we teach them yeah.

Philip Holt (26m 30s):

As they need them. And we've also got a good library and people can kind of pull in those solutions themselves and that learning for themselves. So again, we very much focus, I would almost say fixate on, it's gotta be a real business problem that the site director and the team cares about. If they really care about it, it's worth doing. If they don't care about it, we we shouldn't be doing it.

Mark Graban (26m 55s):

Yeah, Yeah. I mean I I I love the way you say all that. I mean, it's, it, it sounds like it's a shift from like, you know, that company I used to work for, you know, it was easier for them to structure it as, as a big batch, a big batch of training. We're gonna do this batch certification and certify you in all of this, which then slowed down the project where, you know, I mean there, there were different objectives. There's learning certification if you decide that's important. And then the business results, what I hear you describing is it seems like a parallel of a shift between batch to just in time, just in time learning.

Mark Graban (27m 36s):

Does, does that mean, you know, does that mean the certification time to certification is, is slower than, is the learning and the application is happening more organically to the needs of the business?

Philip Holt (27m 51s):

No, we, we, our certifications are based on is this person a good problem solver at the appropriate level are this solving business problems? So I, I put I, I'd put up our Six Sigma green belts and black belts against any six green belt, black belt in terms of solving business problems. If we want to go and have a university academic competition, then, you know, they may lose. But, but we're in the business of solving business problems, not, not becoming academics at, at this. So I think that the curriculum we've got, it's not a, you know, it's not a, a simplified curriculum. What we've done is we've essentially analyzed the tool set and said, which are the most common tools?

Philip Holt (28m 34s):

So let's teach them really well in those fewer, more common tools. And the more esoteric tools can be pulled in when they're, when they're required rather than, you know, it's the per principle. We're teaching them the 20% of tools that solve 80% of problems. We're not teaching them any less vigorously, we're just teaching them fewer but quicker. And then the certification, we do certification. We actually have a re-certification policy as well. So you need to become certified by solving business problems of a significant size. And then two years later you need to show us that you've continued to solve business problems of a significant size.

Philip Holt (29m 16s):

And if you've not, then you don't keep the certification because what's the point of you not using it?

Mark Graban (29m 22s):

Ah, interesting. Yeah. That, that was, that was, I don't think there was a feedback loop at that at that previous company. I think it was like one certified, always certified, but that, that was a different challenge there where particularly at the green belt level, everybody there was doing a project, and I've talked about this before in other episodes, the, the organizational dynamic was if you, if you had 500 green belt certificates on the wall, I think the number of green belt projects was probably something like 504, because the culture in the environment, and this comes back to leadership in a Lean Six Sigma environment, you, you can train and certify people and get your project knocked out.

Mark Graban (30m 4s):

But is that, it seemed like, you know, you're, you're, you're losing so much potential if people aren't given the time and space and encouragement and coaching to go use that over time, right?

Philip Holt (30m 16s):

Absolutely. Absolutely. And we, we don't want, you know, our, our central team are pretty small. You know what, what we're actually asking is that people who become certified as a black belt in our site, they're then the trainers of the green belts, and then we want the green belts to be the trainers of people doing practical problem solving. And, and it should become a lifestyle, if you will, becomes your lifestyle.

Mark Graban (30m 41s):

And, we'll, we'll come back to living lean here before the end of the episode. But, you know, the other thing you mentioned there, Philip, I, I, I totally agree with, is starting simple. I'll, I'll give a shout out. Cleveland Clinic, I think is a great example in healthcare where they have a lot of, you know, smaller kaizens, Just Do Its, or you could say just PDSA it's, and then they have A3s and and they'll escalate a situation to an A3 when they realize, oh, we don't really understand what's going on. And we try to simple countermeasure, we've learned what we don't know then becomes an A3. Where there, there's, there's times where I've been in the difficult situation coming into an organization where they'll say something quite literally like, well, everything has to be in A3.

Mark Graban (31m 31s):

Well, why do you think that? Why do you believe that? Well, so somebody had taught us that right now they're sort of grounded in this idea of, you know, everything needs to be an A3. And then what I see is, you know, it's, it's, it's overkill. People don't, they end up not really working on the problem when they're given, you know, structure that's just too much or, you know, I feel like a heretics sometimes if, you know, I say, I think you, you were saying the same thing. You, you don't always need to do root cause analysis. So I'd be curious to hear your reaction to that, to that phrase or anything else you would have to say about, you know, when you would just, I, I love, I hadn't heard this phrase “3C”: concern cause countermeasure and not going to root cause it sounds like you would agree — not always necessary.

Philip Holt (32m 19s):

Oh, ab absolutely Mark. Yeah. And to me that's how you get that engine of problem solving on a daily basis by not overwhelming, you know, I mean especially, you know, the, the operators at the end of the day, it's, it's one thing that I always try and get across to my team and, and to people we teach you are not value add right in the shop for is we've gotta respect the operators who are adding the value. You know, ultimately they're the people who do what the customer pays for and you know, their time is consumed. We're doing that most of the time. So we need easy ways for them to solve the problems in a way that they're going to do it and not just work around it. So A3's a very powerful tool for, Hey, I've got a concern every time I, you know, one out of 10 of these parts come out of the machine with, with too much swarf on them.

Philip Holt (33m 9s):

Okay, let's knock that concern. What do you think the cause is? Quick conversation, couple of the operators, a team leader, Hey, we think it's this, right? What do you think we could do as a countermeasure, right? Let's try that. Either do it themselves or grab the engineer and you can do a quick fix for them. And if it doesn't work, try something else the day after or, or in a couple of hours. But you know, not getting into too much a free of it suddenly becomes something to can't solve and it's a big enough problem. Then we might get the engineer and, and she and a couple of people might start working on an A3 to really solve the problem from a root cause perspective. But first and foremost, just give the operators that opportunity to try and solve their own problems quickly and easily.

Mark Graban (33m 54s):

So that the, the first book we've been discussing is Philips's second book. I think I said this right the first time. I'll temp fate and say it again. The simplicity of lean, defeating complexity, delivering excellence. So maybe, you know, a final question about that book, you know, Philip, it, what do, do you have a sort of ready standard elevator speech version if somebody says, Well, hey, I've, I've heard about this lean thing. What, what, what is that, Philip?

Philip Holt (34m 23s):

Yeah, so my, my elevator pitch is it's about giving everybody in the organization the opportunity to do their best every day and to feel completely engaged and fulfilled by the work that they do.

Mark Graban (34m 36s):

That's said very simply and very clearly. So that's great. Thank you for that, Philip. And then the, the first book Leading with Lean, an experience based guide to leading a Lean Transformation. You know, we talk more about leadership, but I wanted to ask you first your thoughts on the word transformation. Like that, that's a word that gets thrown around a lot. People talk about transformational change, transformational leadership, lean transformation. What, like, to, to you, how do you define transformation? Like what, what, what's the, the, the boundaries where you would say, this organization isn't just doing lean, they're they're being transformed.

Mark Graban (35m 20s):

How, how would you describe the difference?

Philip Holt (35m 23s):

So, so for me, the reason we use transformation as the word rather than change or transformational change, rather than just simply change is because, well, the definition for me is when it really fully in line with the strategy of a company or an organization to be significantly different tomorrow than it is today. And if lean is aligned with that, and if lean is the vehicle to do that, then lean is being used for transformational change. So that, that's how I would define it.

Mark Graban (35m 55s):

Yeah, it seems like with that would come transformational results we're not just a little bit better than we were last year or a little bit more, a little bit better than we were five years ago, that you see a huge leap in performance. I mean, the first example of it I saw in my time at General Motors, you know, the, the, the plant I worked at was literally at the bottom of the GM global rankings for quality and productivity, predictable results with the old predictable style of leadership. But then we had a lean leader come in, he was one of the original GM NUMMI people, difference in leadership style and leadership behaviors.

Mark Graban (36m 36s):

I saw a lot of improvement in that first year I'd left to go to grad school, but within a couple years that plant was top quartile. I, I would say that was transformational results right there. Like what, what are some examples of transformational results that, that you would see or expect to see as a result of that alignment, that transformation and leadership and culture and improvement?

Philip Holt (36m 59s):

Yeah, absolutely. I mean we, we've got to be looking from a, you know, basically the way I always look at our key performance indicators, which are ultimately how we should measure the performance of the business are around people, engagement of people. And that can be measured through kind of the conventional engagement surveys, like a Gallup engagement. But also in terms of how many kai in per person per month are you seeing how many hazards solved? Then you've got safety, are you seeing a significant change in the performance from a safety perspective? So, you know, zero accidents has to be the goal of a company that really wants to transform. Again, you've gotta come down that Heinrich triangle or pyramid down to the bottom and really maximize the number of hazards solve.

Philip Holt (37m 46s):

You're gonna see quality improve significantly. You know, it's gonna be first time right? Culture, you're going see delivery where it's just right on time, every time you're see reduced in of the working capital that you need to invest. So get it because you're going to reduce your value stream lead times by getting it right first time with high quality. And then ultimately what's gonna come out the other end is lower cost. And what you'll notice is that I deliberately put them in that order, right? Look after your people in a safe environment with, with high quality to deliver on time to customers at a reduced working capital level equals all cost to serve.

Mark Graban (38m 30s):

Yeah, yeah.

Philip Holt (38m 31s):

And and often we use the over way around, right? Yeah,

Mark Graban (38m 36s):

Yeah. Well, so it comes back to that question of is it mistaken understanding of lean or are we just doing altogether different things and labeling it lean, like back to the thing you were bringing up earlier, this idea of a system, whether it's, you know, 14 points of the Toyota Way, if you pick and choose a couple of those points or we're gonna, you know, do all these lean things, but we're not gonna embrace, you know, point number one about long term thinking. Like you're doing a lot of things, but should you be labeling that lean anymore than, let's say, I would say I'm following the keto diet, I eat lots of bacon cheeseburgers, but I still eat buns.

Mark Graban (39m 18s):

Like, well that that's not the keto diet. Why would you be calling it that? And why would you be expecting, Then you might say like, well I'm doing the keto diet and I'm not losing weight. Well, yeah, because you're not doing the keto diet. They're, they're similar things that happen with lean. If people are really doing cost cutting, but they're calling it lean, that's very different, right?

Philip Holt (39m 36s):

Yeah, absolutely. And, and you know, I often joke in my, in my first bulk, I, I coin the term, you know, people often think of lean as less employees needed.

Mark Graban (39m 48s):

Yeah. We've all heard that. Yeah,

Philip Holt (39m 50s):

Exactly. And it's, you know, and I I say lean really should be about leadership excellence analysis and no, and that's the intelligent, no. So yeah, you know, we, we've got, we, you know, my and and the reason I write my books, the reason I do things like this when I'm talking with you, Mark, and you know, I'm, I'm passionate about changing the mindset because it has such great impact and it is transformational on an organization and it's people when it's done right. Yeah.

Mark Graban (40m 21s):

And, and I'm glad you mentioned safety cuz even back in the auto industry, I learned, you know, you know, it was often articulated SQDC – safety, quality, delivery cost, and as you said, cost being an end result of better safety, better quality, better delivery, where, you know, the cost cutters might hurt quality delivery and safety in the name of cost-cutting. So then we're, we're, we're worse off. But I'm, I'm, I'm glad you mentioned even the idea of zero accidents as, as a goal. You know, first off, that pyramid that Philip referred to, if you're not familiar with it, you know, talks about not just reacting to let's say deaths or lower in the pyramid, serious injuries or, you know, other injuries near misses and risks.

Mark Graban (41m 8s):

We, we wanna be identifying risks and reacting even to near misses in the name of improving safety. Right. Philip, what, what, what else would you say about sort of focusing on, on the bottom part of that pyramid as, as you mentioned?

Philip Holt (41m 21s):

Yeah, it's, it's, it's about creating, you know, having a value, creating safety culture, you know, and it's is really about, we want to help everyone to see, you know, we talk about learning to see from a waste walk perspective, but this is learning to see hazards and, and really having a very low tolerance for unsafe conditions. And, and one of the key elements of our lean operating model in aerospace and, and one of the hoshin targets for this year has been behavioral based safety, which is a way of teaching and training people how to be and behave in a, a safe way that is about spotting those hazards upfront.

Philip Holt (42m 7s):

You know, we even talk about we want people to go home in a better state than they came to work. Not, not even just in the same state. We want 'em to come home in a, a better state. And you know, that it's a mindset, it's a change in mindset and it, it's, it's big. I mean, you get, you get a lot of resistance to it because there, there are people who've been ground into with both safety and quality, and I think there are two sides of the same coin. I it's a very similar mindset and they've been grounding that behavioral idea that safety and quality cost money,

Mark Graban (42m 42s):

Right? Right.

Philip Holt (42m 43s):

Instead of they actually create value and I'm very much on the, they create value side of the coin. Yeah,

Mark Graban (42m 50s):

Yeah. That old trade offs thinking. And, and, and so much of what you just said there in the last couple minutes reminds me of what Paul O'Neill said when he was CEO at Alcoa, where they had learned from Toyota, they had what they called the Alcoa Production System later the Alcoa Business System. But, you know, Paul O'Neill as a leader said the goal is zero harm. And he heard him say that same phrase, that the goal evolved to be you should go home healthier than when you arrived. And, and, and there's a certain culture and you know, as you said earlier, it starts with the CEO, right? You know, Paula Neil would teach people, Nope, these are false trade offs, you know, better quality doesn't cost more.

Mark Graban (43m 37s):

That's an old mindset in healthcare. People say the same things like, Oh sure, we'd love to have better quality, but we can't afford it. Well, yes you can if you go about things in, in a lean way. So I'm I'm, I'm really happy to hear those same thoughts, you know, kind of, you know, being, being part of your approach and, and, and whenever that's how it is at other companies, that's just always great to hear.

Philip Holt (44m 1s):

Yeah, absolutely.

Mark Graban (44m 3s):

Now, you know, there's an old habit, you know, around tradeoffs. There's an old habit, you know, people will make excuses like, well, you know, in, you know, it's sad that injuries are bound to happen. That was something Paul O'Neal challenged. So I I was gonna ask one other question about lean leadership here. You know, it's one thing to sort of try to explain or demonstrate what lean leadership is. What, what have you learned about helping people unlearn old mindsets, old habits, old behaviors, so they can then embrace lean?

Philip Holt (44m 37s):

Yeah, that's, that's really a beautiful question Mark cuz that's been one of my real educations in, in this. I'm an engineer, so I I come from the side of PDCA logic, you know, why do people not understand it? And, and I've learned over the past few years, you know, it's very much about getting people's hearts, capturing their imagination, really understanding what's in it for them and what what will help them. And one of the models that's really helped, you know, we, we all know the de sh PDCA model, but we've adopted over the past couple of years, the BVIs B TFA model, believe, think, feel, and act.

Philip Holt (45m 25s):

And, and I've incorporated that in my third book that is important to me now. And, and that's really about helping people emotionally to understand why we're doing something and to understand what drives them. And that's been one of the biggest things about how do we help people to one, learn behavior. People are doing it for a reason. They, they believe something which drives their thinking, which they get a reaction on, and they experience things that makes them feel a certain way and they therefore act a certain way. And what we've gotta do is we've got to, you know, get in there somehow to show them that a new way of working gets a result that makes them feel better.

Philip Holt (46m 8s):

But once they start to feel better about it, they'll start to think differently. They'll start to believe different things and they'll start to act in a different way. So that, that's really what a lot of the emphasis is on an, you know, in my team and beyond my team in the sites now you hear people talk about bt a it's part of a training materials. We, we've got something in our materials called the Psychology of Change. So it's really trying to drive this up and and mortar really in terms of how we help people to behave and, and think differently.

Mark Graban (46m 42s):

Yeah. And so then when we think differently, this comes to your third book, We, we can live differently. That third book, I'm gonna say it right this time, I think Leading Lean by Living, Lean: Changing How You Lead, Not Who You Are. Well, so I'd love to hear the story of how, how this book came to be, because you write more about personal benefits from lean both at work and at home.

Philip Holt (47m 9s):

Yeah. Ab absolutely. So what one of the, one of the questions I I I go off people, you know, he'd write the books and, and also people I work with, people in my team and, and peers and colleagues is, you know, how, how do you get so much done, Philip, but you never seem to be kind of, you know, doing the 70, 80 hour weeks and, and you, you have a smile on your face even when you've had a long travel week where you've been flying to the west coast of the US and you're back and you know, you'll come on a meeting on afternoon after you've got back off the flight and you've got on your, you know, what's going on, can you do this? Started to think about it and, and talked to people and I'd done a couple of presentations to companies and, and to people and, and people just said, Look, I, you need to write this down.

Philip Holt (47m 57s):

You need to put this in your third book. You need to tell us how you do this. So that, that's how it came, came about. And it's really because in, in my own personal reflection what we call hci, that that's been the key driver of how I've changed my behavior, how I've changed how I lead, and I've not changed who I am. I, I'm ly as I said, I'm from the Manchester area. I've got my own accent, my own background, my own cultural beliefs that, that have driven who I am. But at the same time, I've learned to change to be a different leader. And I've done that by living the lean behaviors. And you know, there's so many people I've coached who might have the job title lean expert or lean master or continuous improvement leader who are overwhelmed.

Philip Holt (48m 45s):

And, and sometimes I can sound a little bit unsympathetic because, you know, I'll say, Look, this, this isn't, this isn't acceptable. Don't tell me you're a lean expert and then tell me that you're overwhelmed. You can't keep up with your email and you can't keep up with your workload. Those

Mark Graban (48m 60s):

Are problems to be solved.

Philip Holt (49m 1s):

Right. Those are problems to be solved. Absolutely. You know, this is like going to Doctor who sat there is, you know, 10 times overweight, sat smoking a cigarette, drinking a glass of whiskey, and telling you you need to lose weight and stop smoking and stop drinking. You know, it's, it's, it's about solving the problems that are getting in our way. So, you know, my, my last book, Leading Lane by Living Lean is really how, how do you become that great leader you want to be by living the concepts yourself, reducing the burden on yourself, reducing the burden on your family, your friends, your social life and, and creating what I call a life imbalance.

Philip Holt (49m 42s):

I really hate the term work-life balance, because to me, work-life balance implies that you've got this great thing called life, and then you've got this horrible thing called work. Yeah. And you've gotta reduce the amount of time at work and maximize the time that you're at life. So basically it says you're wasting your life when you're in work. That's, And I, yeah. And, and I don't believe that what I believe is work is an integral part of a positive life, Right. And a life imbalance embraces it and, and makes sure that you've got every part of your life how you want it to be. And that's, that's one our book's about how do you create that? How do you achieve that, that nirvana, if you will.

Philip Holt (50m 22s):

Yeah.

Mark Graban (50m 23s):

So there's, and and, and you know, as you shared Philip, your reflections about shifting from tools focus to leadership focus, there's opportunities then it seems in our home life, like I, I, I see times where people will, will share, here's examples of me using lean tools at home. I'm like, Hey, if that, if that solves a problem for you, if that works for you, well great. But it sounds like you're, you're, you're not just focused on here's, you know, five s for the, the kitchen pantry or a system for buying more toilet paper. There's, there's more to it than the lean tools at home, right?

Philip Holt (50m 59s):

Oh, ab absolutely. This is about doing what works for you to reduce your time. So you know it, and it starts with mindset, again, it starts with belief. You know, I do a very simple mathematics equation on, you know, working 40 hours instead of working 52 hours a week, but reducing the waste, that means you're working 52 hours a week so that you get exactly the same amount of value-added done in 40 hours as you would in 52. And it gives you 12 hours a week that you can choose what you want to do with. And it's not up to me what people do with that. Maybe they want to spend that 12 hours working again, but maybe they can work on something that's about the future instead of just fixing what's going on at the moment.

Philip Holt (51m 44s):

Or maybe they want to spend that 12 hours with the children, 12 hours with the friends playing chess, whatever they want to do. But it's about how do we take it out? So it's, again, it's just like the discussions we've had about starting with problems. What is the problem for a business? What's your problem? What's your personal problem or problems that you want to, to solve? Is it not having enough time with the family? Is it not having enough time to learn tennis? What, what is it? And also the, the side effect is you'll become a role model at work as well. And I think that I wouldn't be in the position I am now as a senior vice president if I hadn't been able to become the leader that I've become by Living Lane.

Philip Holt (52m 30s):

That's, that's, that's the premise. Yeah.

Mark Graban (52m 33s):

Well thank you for Philip and, and thank you. Thank you for that. And thank you for everything you've shared. Just one of the last thing we, we had talked about this before we started recording is we're trying to turn off devices that make noise. And they, you know, a lot of this is from push notifications. You know, we, we often say in, you know, in lean frameworks we'd say, you know, push of materials is bad, pull is good. There's a little bit more nuance view. I've heard people say, you know, flow when you can pull, put, you know, pull when you must, or you know, sometimes there's, I'm stating this really badly. There's there, there's a time and a place, even if push isn't the ideal, sometimes a little bit of push can fit into the context of a lean system.

Mark Graban (53m 17s):

So that was a really badly formed question around push in, you know, push notifications versus pulling for information. Tell us about some of the settings and the way you manage some of your devices there, Philip.

Philip Holt (53m 31s):

Yeah, so in terms of notifications from emails, social media, WhatsApp, etcetera, I don't have those pinging, I don't have those making noises. The only thing that makes a noise on my phone is, is a phone call. And on my work laptop it's, if somebody calls me on teams, everything else is, is on a pull system. I go take a look at my email when my standard work, my latest standard work tells me it's time to go take a look at my email. I go take a look at LinkedIn. I'm, I'm quite active on LinkedIn, but I'll look at it at the times that suit me and fit with my leader standard work.

Philip Holt (54m 11s):

So, you know, it's very much about a pull system on that. And, and if somebody needs me, they can call me and, and you know, my team, my colleagues know if they give me a call, I'll always pick up if I can, if I'm, and, and if I can I'll call them back. So again, it's about taking control. It's not about ignoring. And I think a lot of, a lot of the problem with many time management tactics nowadays are they're about how do you ignore what's going on and that doesn't reduce the psychological burden.

Mark Graban (54m 42s):

Yeah.

Philip Holt (54m 43s):

To reduce the psychological burden you need to be in control of, of the stresses

Mark Graban (54m 49s):

Or, you know, take control back. As we wrap up, I think of something you said just a little while ago, if someone's complaining that they're overwhelmed by all of those notifications, that's a problem to be solved. Like, you know, for me it's iPhone go into your settings. Like, I'm pretty aggressive about not letting many apps give me notifications for that same reason and turning off, like on my iPad there's like, there's no notifications cuz I don't use the iPad in a way that would invite any sort of, you know, urgent interrupting sort of message. I I'm reading in the Kindle app in my iPad. And so if I haven't completely solved the problem, I've implemented some kaizens in my own management of these devices.

Mark Graban (55m 35s):

Yeah,

Philip Holt (55m 36s):

Yeah. Precisely

Mark Graban (55m 38s):

Small improvements, no root cause analysis, but we, we made it better. So Philip, you know, I really wanna thank you for taking the time out of your day. This is not part of your usual leader standard work to be a guest on a podcast, I'm guessing.

Philip Holt (55m 52s):

No, it's not. But I don't leave enough time to do this.

Mark Graban (55m 55s):

Yeah, well I'm glad that you did. I hope people will go check out Philip's books and see there, there's one of those noisemakers popping up and getting me a reminder for something. So I apologize for that. But go check out Philip's books, you can find them on Amazon and other booksellers. His website is leanmaster.com and again, there'll be a link in the show notes. So Philip, thank you for sharing. You know, so many, you know, great stories and reflections and insights today. Really appreciate it.

Philip Holt (56m 25s):

Yeah, you're very welcome. And thank you for having me, Mark. It's, it's a privilege. Thank you.

Mark Graban (56m 29s):

Well, thanks again to Philip Holt for being our guest. To learn more about his books, you can look for links in the show notes or go online to leanblog.org/460.

Announcer (56m 40s):

Thanks for listening. This has been The Lean Blog podcast. For lean news and commentary updated daily, visit www.leanblog.org. If you have any questions or comments about this podcast, email leanpodcast@gmail.com.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation: