Last month, I had an opportunity to visit the Toyota North American Headquarters that's now near me in Plano, Texas. Thanks to the MIT Club of Dallas / Fort Worth and the Public Relations Society of America chapter for creating this opportunity.

Before touring the “Experience Center” that had the virtual tour, there was a panel of Toyota leaders talking about communications and public relations.

The Experience Center, as cool as it is, is not open to the public (at least at this point). A Toyota leader talked about how they want Toyota team members to invite people as their guests and to feel like “hosts.”

They said:

“The customer is center of everything we do.”

To that point, the Experience Center has a live, working “customer service center” that takes phone calls as one way of better understanding the “voice of the customer.”

One of the panel speakers, Brian, had a background in engineering and production. He took a role in communications right before the allegations of “unintended acceleration.”

That's something I talked to Jeff Liker about in a podcast about his book Toyota Under Fire (and Brian was one of the people who talked to Jeff for the book):

One lesson shared by Brian:

“Don't assume your reputation will carry you through a crisis.”

He also talked about working with reporters and looking internally for improvement instead of blaming reporters, when he asked:

“Where did we go wrong that we're not being believed?”

The whole episode, according to another Toyota leader, Nan Banks:

“It's made us better communicators and a better company overall.”

Toyota has learned that the lines between “internal communications” within a company and “external communications” have blurred.

The communications team was “challenged to come up with innovative ideas,” so they converted a storage closet into a podcast studio and released a podcast called “Toyota Untold.”

They also have a series of videos called “American Journey.”

I appreciated hearing the perspectives of the Toyota communications team, but the highlight of the evening for me was a chance to walk through the Experience Center. There were many cars from different eras on display, including this old Toyota Corona:

For everything in the Experience Center, I was blown away by the “virtual reality tour” of the Toyota plant in Cambridge, Ontario.

Here are some photos of me wearing the VR gear (which runs off of a smartphone) — click any photo for a larger view:

It was an incredibly immersive experience. I've been on Toyota plant tours in San Antonio and Japan and it very much reminded me of that experience.

Once I got oriented in the VR goggles, I realized I was on a tram that was driving through the factory (this was very reminiscent of the tour in San Antonio).

The VR was amazing, as I could look up, down, and around in 360 degrees (and those rails were very helpful to hold onto).

But, the VR tour was better than a physical plant tour in that it took you through the stamping and paint shops (areas they avoid in a physical tour due to safety, noise, and possible human contamination of the paint).

There were times when the VR tour perspective put me literally INSIDE of a car that was going down an assembly line. I could see team members installing parts inside the car I was “in.” They took the car through final inspection and out to a rail car for shipping (again, with me being virtually inside the car for that).

I'm going back to Japan again in December and that trip will include a Toyota tour. It's amazing to see the possibilities that arise from a virtual tour of a Toyota plant.

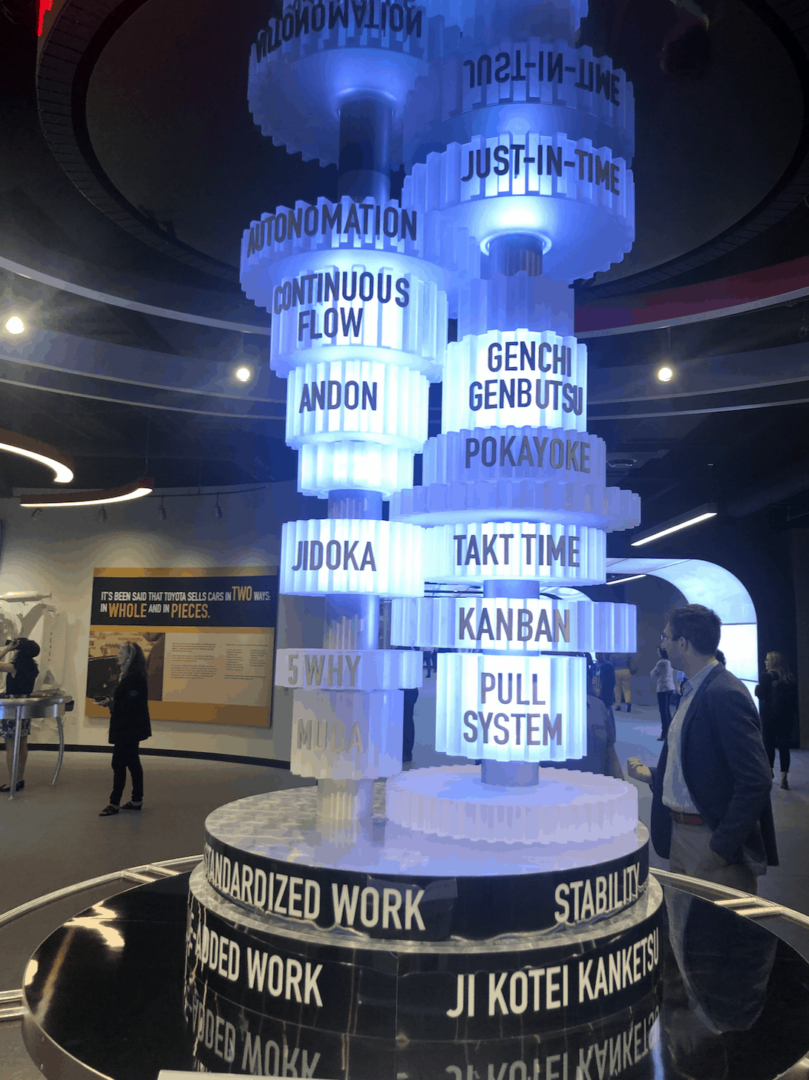

The Experience Center, of course, had displays about the Toyota Production System. There was a display that explained some of the core TPS terminology:

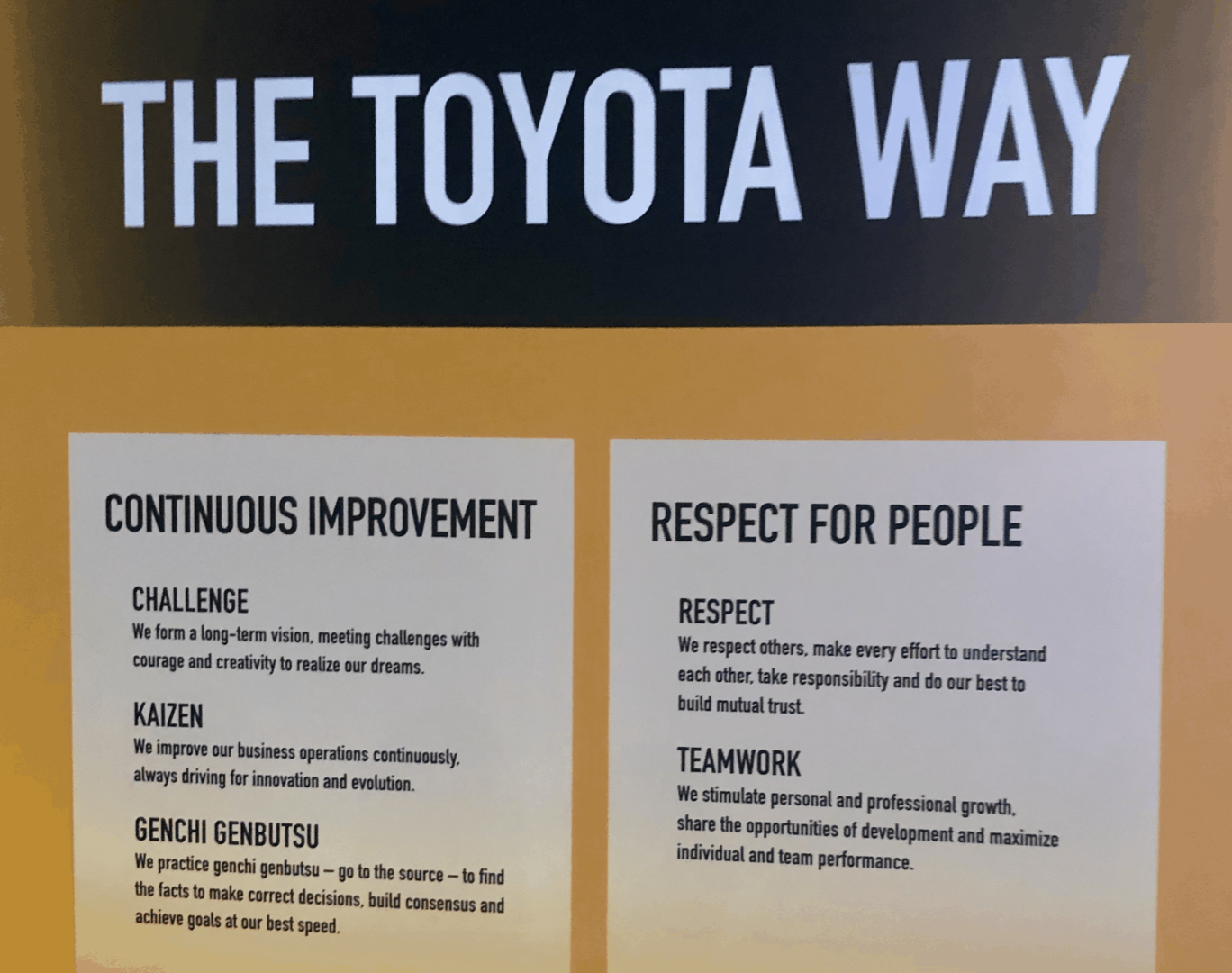

Before diving into details, there was a display about the dual pillars of The Toyota Way management system (click for a larger view):

What are some of the other terms that the digital display defined?

Read more about those three pieces the the philosophy in this blog post:

Kaizen involves everybody, everywhere… changes large or small.

Read about a Toyota tour guide's Kaizen in Japan, as an example of that:

Toyota says that standardized work is necessary for Kaizen.

One way Toyota solves problems is through “the five whys”:

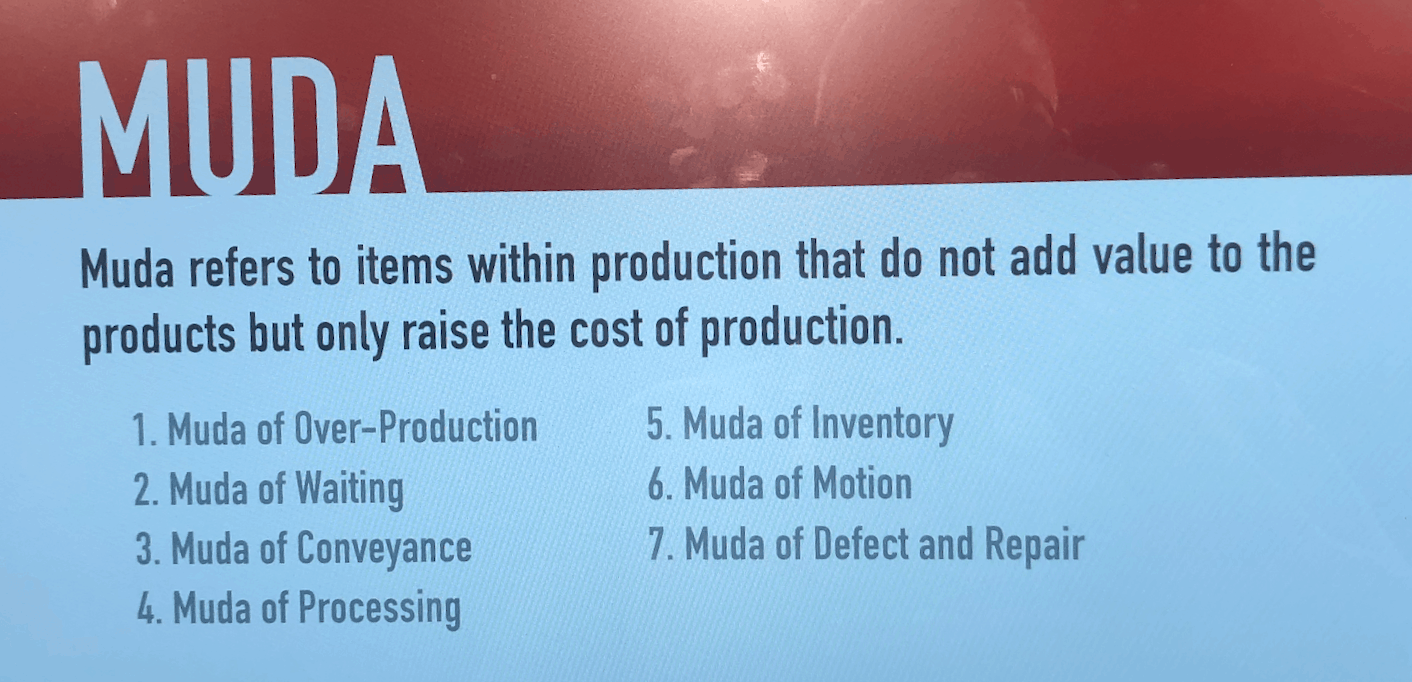

Toyota talks about the “seven types of waste” — not including what many call the “eighth waste” of human potential. Maybe it's just assumed, at Toyota, that people are engaged and, therefore, that waste doesn't exist?

And a few more:

See, Lean isn't “all about efficiency,” as some Lean Six Sigma people teach. TPS (and therefore Lean) is about flow and quality.

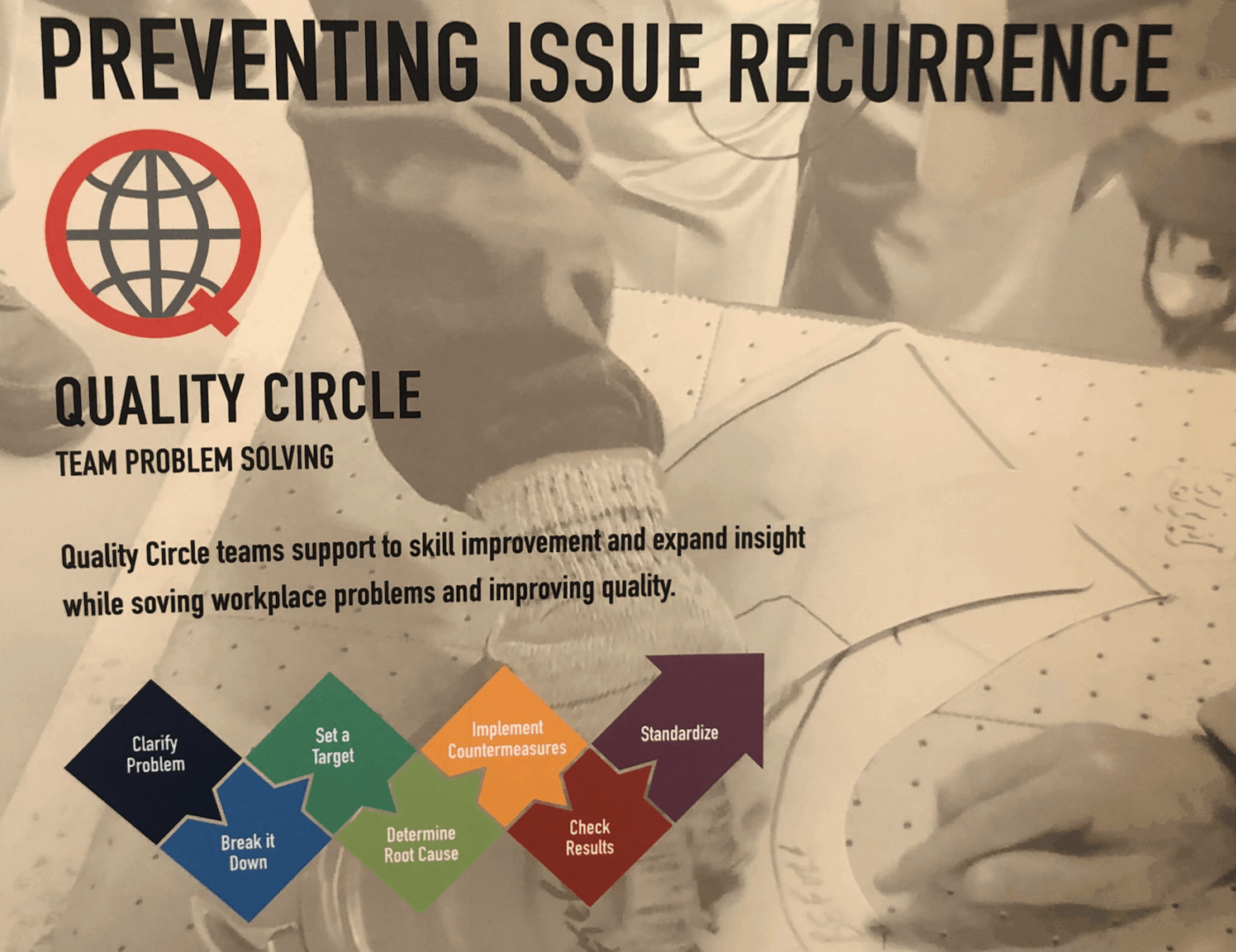

Another display described the “quality circle” approach (something that dates back to the days of Toyota Quality Management and it's alive and well in Japan):

The steps are:

- Clarify Problem

- Break it Down

- Set a Target

- Determine Root Cause

- Implement Countermeasures

- Check Results

- Standardize

Here's a blog post about quality circles in Japan:

There was so much cool stuff to take in at the Toyota Experience Center. I hope you can get an invitation (or maybe it will be open to the public, at some point, like the similar center in Japan is).

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

Great article, and what an amazing experience! I believe the lessons you shared are great, particularly the point “don’t assume your reputation will carry you through a crisis”. Often times large companies can consider themselves too big to fail, and believe their name will carry them through different problems. Toyota does a wonderful job sharing their knowledge, and insight into their practices. The VR tour of their facility in Ontario is a great way to give visitors a “real life” experience more so than even if they went in person (not being able to see certain areas of the factory). Thank you for sharing.