I

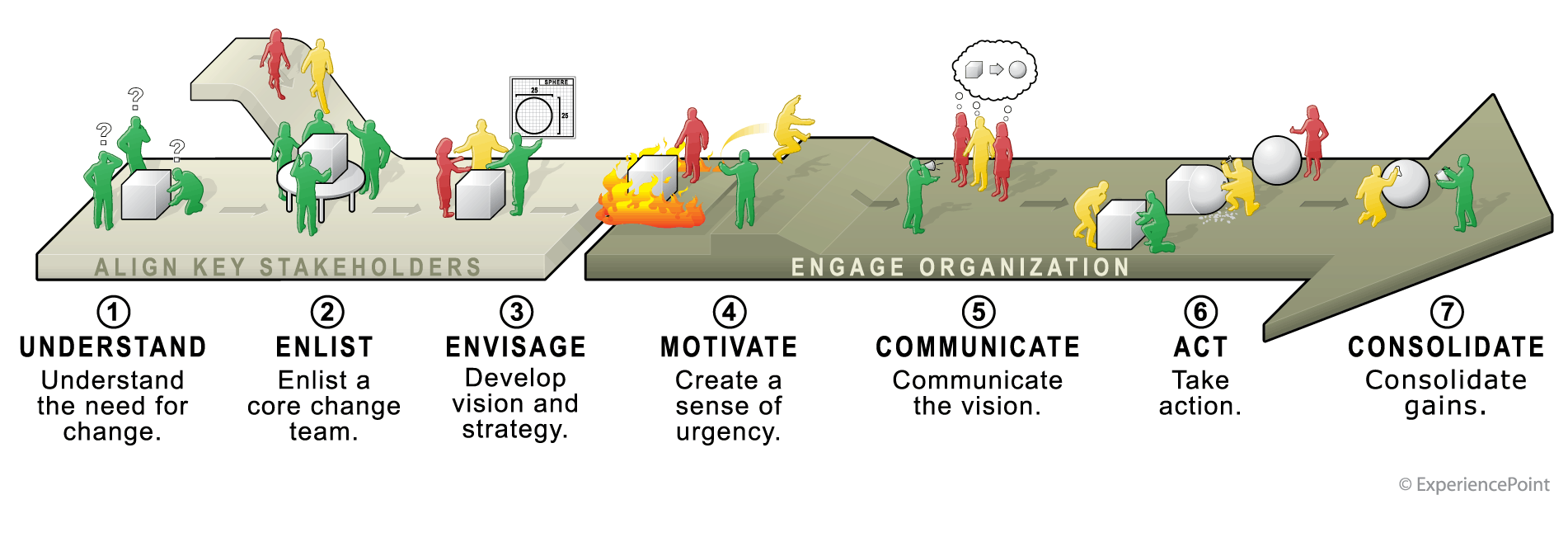

Playing the healthcare-based “Lakeview” hospital simulation and learning about the ExperiencePoint change model, shown below, was really

This experience made me wonder: Why had some organizations not really embraced “Lean management” principles even though their business was really struggling? Why did some leaders expect others to just follow their command to “get Lean” and to do things differently?

In the course of my early years in healthcare, I worked for a consulting group that had a somewhat implicit model for improvement projects that included change management elements that mapped pretty closely to the explicit ExperiencePoint model — and a majority of those initiatives were successful and sustainable — probably at a higher rate than you'd see out there in general.

It's one thing to have knowledge about Lean methods; leading people and affecting change in an organization is very difficult. In other words, it's one thing to know how Toyota does things — those are facts. But, how do we get an organization from where they are today to a Toyota level of performance? That requires more than subject matter expertise — it requires effective change management or, perhaps, change leadership…

Far too often, people learn about a methodology, like Lean, or a specific tool, like Kanban or 5S, and, in their excitement, they push the new approach on others. Not surprisingly, this push leads to a lot of push back. It's a natural human response (and it sounds like that law of physics about an equal and opposite reaction). Pushing change on others doesn't work. Or, it might work for a while, but ends up being unsustainable.

I was guilty of this in my early years (as I've written about in the anthology book Practicing Lean). As an engineer, I would develop a solution to a problem and it was my job to push it on others. Then, managers and I would wring our hands about why people weren't using the new tool. Didn't they realize there was an important business problem to be solved? Didn't they know a new way was necessary?

Ah, those difficult questions… the answer was, too often, “No.” From the standpoint of the workers, they were comfortable with the way they had always done things. It was natural that people would reject a new way or revert back to the old way when managers weren't looking. In situations like that, we shouldn't blame others for being “resistant to change.” We should reflect on the way we (as engineers or managers) didn't fully engage the people doing the work.

When I started working in healthcare, I was taught (and developed) some methods that fall very much in line with the ExperienceChange model. Instead of rushing ahead to take action, we formed a core group within the client's hospital department. Having a cross-functional team dedicated to the change initiative for a period of months allowed me, as the consultant, to fully engage them since they were freed from the daily work. This core team was able to study and analyze the current state, working with others in their department to create a more broadly-shared understanding of the opportunity for improvement (and the need for change).

The core group had the time and ability to learn Lean concepts, allowing them to create a future vision for a new laboratory layout, a new MRI scheduling process, or things like that. The core group then was able to help motivate the rest of their colleagues, using two-way communication to refine the vision and plan, gaining buy-in through that process. Only then was the team ready to move forward with turning their vision into new workflows and a new reality.

Instead of complaining, after the fact, about a lack of sustainment (as I hear so often in the context of Lean), we created buy-in along the way instead of trying to create it after the fact (when it's too late).

Without an effective change management model and approach, I might have continued to be trapped in that ineffective cycle of being an expert who was tasked with coming up with the correct solution.

Clients would sometimes ask, “Wouldn't it be faster if you just told us what to do from your experience?” “Sure,” I'd respond, “But that won't be effective or sustainable. We'll come up with better solutions as a team and that engagement is exactly what leads to sustainment.”

As I've learned, the hard way, having the right solution isn't enough.

Seeing others struggle with change (and the lack of a change management methodology) motivated me to get certified as an ExperienceChange facilitator a few years back. I'm just sorry it took me so long to do so! I appreciate the model and simulations that ExperiencePoint provides. They resonate with people. The workshops I run open people's eyes in a fun, non-threatening way. And that leads to greater success with Lean (as it would with any other large-scale change).

I'd love to help you and your organization. Let me know if I can bring this interactive workshop experience to your workplace. Contact me today.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

One thing that I have learned over the years is that people don’t like change. They like to stay in the flow of how things are and continue doing whatever they are doing in that set way. In order to bring about change, you need to get everyone the change affects on board. You want them to be heavily invested in the project like you are so they understand the importance of change and it will make the change easier for them, understanding the implications of that change.

It’s more complicated than “people don’t like change.” People generally like change that they view as an improvement. People tend to like their own ideas more than the ideas of others. Another reality is that people are AFRAID of change… even when it’s logically positive or beneficial.

That’s where the psychology and work of Dr. Robert Maurer is really helpful, related to Kaizen:

https://www.leanblog.org/2012/07/podcast-153-robert-maurer-phd-the-kaizen-way/

Check it out…

Loved the Article! I was especially interested when you mentioned using two-way communication to refine vision plans, and I believe that it is certainly the gateway to sustainability. I was wondering what would you do if, when starting this two-way communication, you get met with very strong resistance anyways due to workers loyalty to their methods?

If there’s “strong resistance,” then leaders need to continue the conversation. Keep talking and listening about the case for change and people’s fears about change… don’t write people off as being “resistant.”

Gary Convis, a former Toyota executive, said he was taught to “lead as if you have no authority.” Falling back on the formal authority of “do this because I said so” is something that should be done rarely.

The ExperiencePoint model is very similar to the John Kotter 8-step change model, which I always have thought to be lacking in steps prior to step 1. Namely, failure analysis to determine the root cause of why change is necessary (or, how the company got into the mess it is in which results in the need for change). The weight of the old way of doing things is so strong that and change that is achieved will likely be ephemeral. Hence the need to identify root causes and implement countermeasures prior to starting step 1 of the change model.

Bob, yes it’s based on the Kotter model. I think the improvement is moving the ‘Motivate” step (a.k.a. “create a burning platform) to step #4. If we create the burning platform before there is a vision for how to improve, people might just get worried and/or jump ship.

The ExperiencePoint model, to me, follows good A3 problem solving. Step #1 involves understanding the current situation, which should include some sort of systems analysis and root-cause problem solving (although complex systems rarely have any single magical root cause of the performance gap we’re trying to close). The initial core team creates an initial vision (getting input from others) and then shares that with the organization more broadly in Steps #4 and #5.

To me, Steps #1 through #5 are the Plan in PDSA. In Step #6, we start testing the countermeasures from the vision in a continued PDSA manner. The vision might not include a completely detailed plan, so that’s developed in Step #6.

The model is drawn in a linear way, but I think there are many PDSA cycles within that high level PDSA cycle… we only do Step #7 (consolidate) if there are indeed gains to sustain. If not, we’d loop back as far as we need to.

We shouldn’t expect people to inherently accept change. The impetus to both create awareness for the need to change and sell the benefit of a specific change pathway should have high thresholds. Because most changes are neither sustained or ultimately impactful. The first thing I do when I work with an organization is review the last 1-2 years of change initiatives. The percentage of “projects” that hit and sustain a predefined target has been anywhere between 3.6% and about 60% (but usually around one third). Which means that 2/3rds of any time spent executing on those initiatives is, by definition, waste and NVA. That also mean that the status quo is likely the preferable path forward over most “Improvement” efforts.

Most organizations don’t measure this (for fairly obvious reasons) and your “probably at a higher rate” is generally telling. Most companies don’t want to know. Most lean leaders don’t bother measuring (or especially quantifying the COPQ associated with it).