I'm very excited to be leaving for Japan for another study trip in a month. This will be my second trip this year, this time with Honsha, after previous (and hopefully future) trips organized by Kaizen Institute.

I learn something each time and I've started reflecting a bit on the previous trips. There's still a lot that I haven't blogged about from the last trip.

Even though the previous tours have been focused on Toyota, as well as Lean and Kaizen in various organizations, one common thread is Total Quality Management, or TQM. In many Japanese organizations, TQM has been a solid foundation of practice for two or three decades, where it tended to be a fad here in the U.S., as I've blogged about:

From 1994, But Relevant Today: “Why TQM Fails” & Parallels to Lean

Methods like TQM, Kaizen, or Lean tend to “fail” when an organization gives up on them.

As I mentioned in this webinar recently, when I first visited the Toyota plant in San Antonio a few years ago, one of the people in the tour group was a Six Sigma (or Lean Sigma?) Master Black Belt. He asked the Toyota team member if they use Six Sigma and they said:

“No, but we teach everybody the seven basic Q.I. tools.”

They were, of course, referring to TQM.

When I've visited Japan, TQM has come up as a topic, as I blogged about here:

“Quality Circles” Are Alive & Well in Japanese Organizations; We Might Call it A3 Problem Solving

TQM at Toyota in the U.S.

And, more recently, Tracey Richardson (formerly of Toyota in Kentucky) was sharing some old Toyota materials that directly reference TQM. I've embedded these below for my own future reference (and yours):

Her Day 9 post references control charts (which I write about in my book Measures of Success).

Again, Toyota doesn't use formal Six Sigma (with “belts” and all) in the factories, but they do, again, teach everybody the “seven basic Q.I. tools” of TQM, which includes control charts (a.k.a. SPC or Statistical Process Control).

Here's the rest of the TQM material from Tracey…

As I've heard them say in Japan, we “spin the PDCA cycle” as we improve in experimental and incremental ways. I wrote about PDCA/PDSA last week.

More about Lean / TPS and quality:

What Toyota Shared in Japan

During my last trip, we visited a hospital that had some Toyota people coaching and mentoring physicians on quality improvement. They shared a TQM guidebook that wasn't shared in the Toyota plant tour. The cover is pictured here:

I love how Toyota emphasizes the “improved vitality of personnel” before the vitality of the organization. The two go hand in hand, of course. That's the same phrase that was in Tracey's first post, by the way.

I love how Toyota emphasizes the “improved vitality of personnel” before the vitality of the organization. The two go hand in hand, of course. That's the same phrase that was in Tracey's first post, by the way.

The first page of the book lists some “Guiding Principles” that include “[fostering] a corporate culture that enhances individual creativity and teamwork value, while honoring mutual trust between labor and management” and “[pursuing] growth in harmony with the global community through innovative management.”

The booklet also says “all personnel” need to “fully demonstrate the best of their unique abilities” in order for the company to be successful.

“TQM activities serve as the foundation for achieving that goal [of ‘creating better cars'] and the entire Toyota family is engaged in TQM activities.”

Toyota adopted “QC training” as a method in 1951 and “started to popularize the quality control concept along with the acquisition of statistical tools.”

Who is to say that Six Sigma has a monopoly on the use of statistical tools?

Toyota then adopted “TQC” (Total Quality Control) in 1961 as a further evolution of quality methods. Toyota was awarded the Deming Prize in 1965. They switched from the TQC term to TQM in 1995.

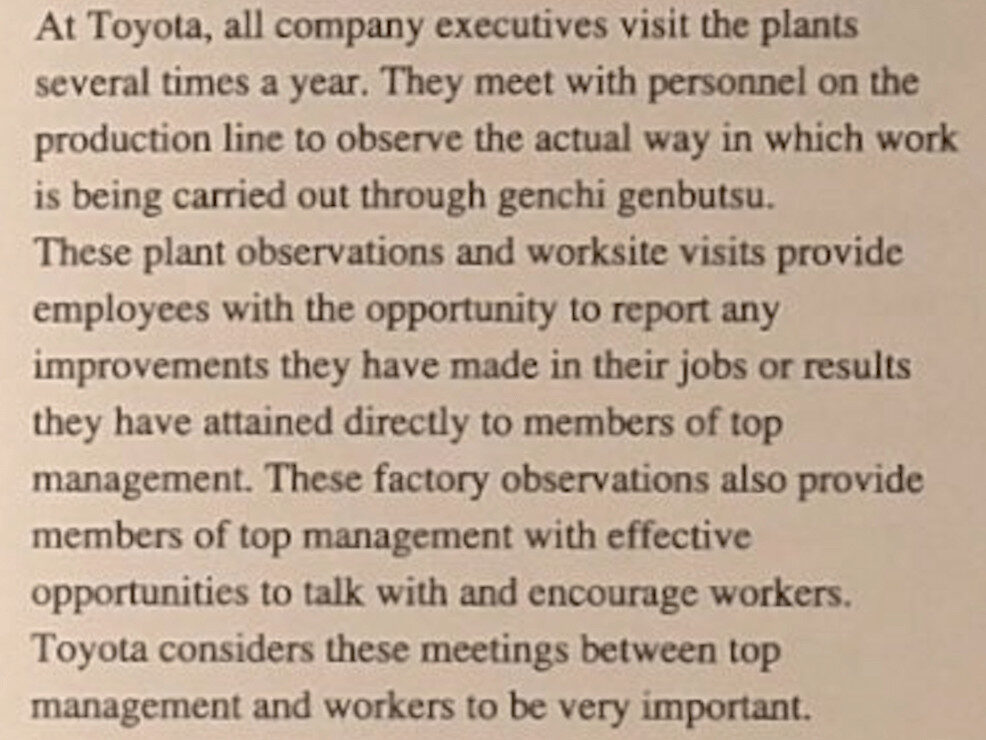

I love Toyota's description of “genchi genbutsu” (referenced in Tracey's one post) or the practice of “going to see” at the “gemba” (the workplace).

I'm often part of efforts to show hospital executives to follow this same practice to the benefit of their organizations. It's always eye-opening for the executives. What have you seen with executives learning to “go and see?”

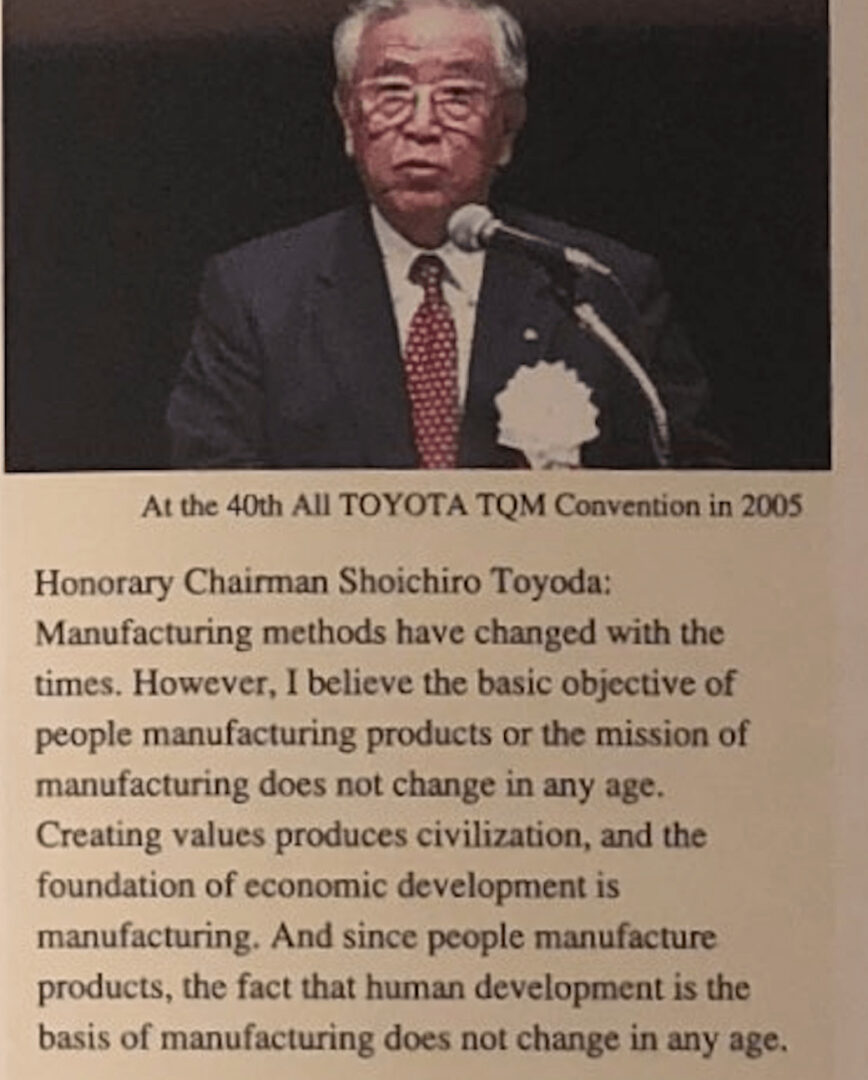

The booklet also talks again about the importance of people development and how “timeless” that notion is.

Different Modes of Improvement

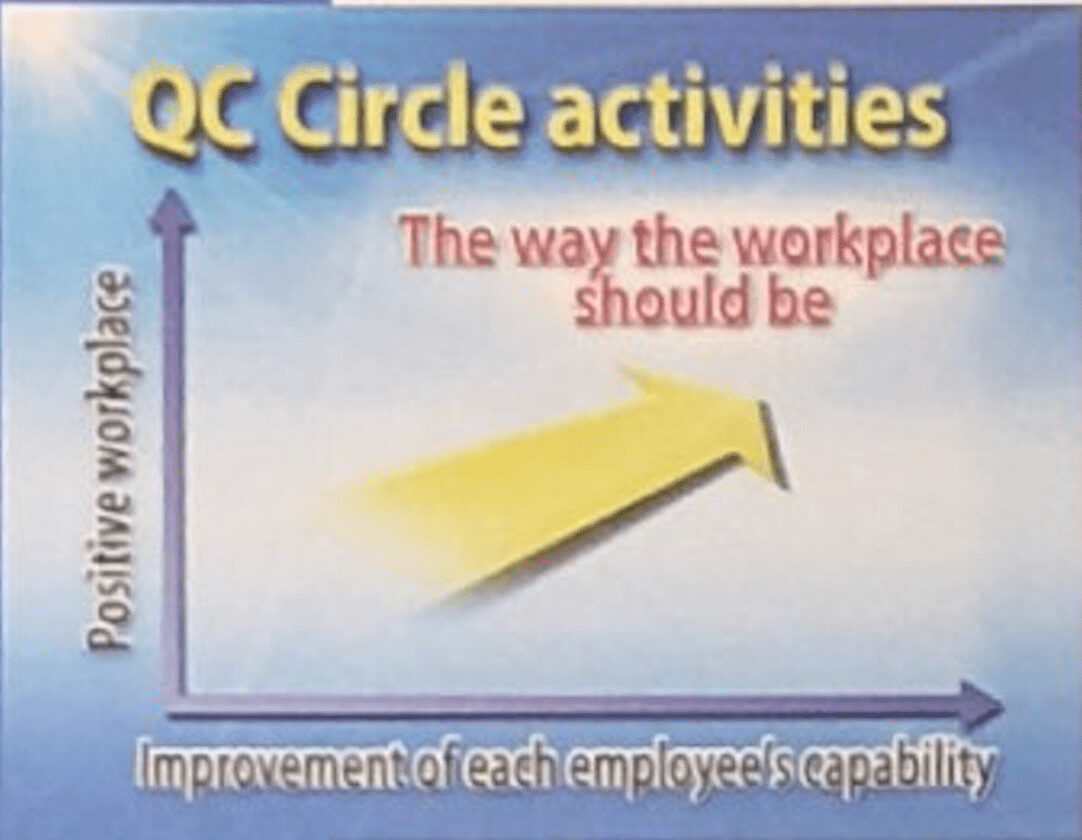

I blogged about “quality circles” in the post I mentioned earlier and Toyota says they use quality circles to improve quality, cost, and safety.

“There are currently 4,500 circles…”

Toyota also mentions their “Creative Suggestion System,” where “more than 550,000 suggestions are submitted annually.” They add:

“The fact that nearly all of these suggestions are adopted indicates the high quality of their contents.”

We can call that a “Kaizen” methodology. Either way, compare that implementation rate to the classic American “suggestion box” system that has historically seen just a 2% acceptance rate or so.

We see similarly high adoption rates (80% or more) in American hospitals that practice the Toyota style of Kaizen.

More about suggestions, engagement, pride, and quality:

As an aside, I posted another complaint on LinkedIn the other day about the common problem of “Lean Sigma” saying things like “Lean is about speed” (or cost or efficiency) and implying that only Six Sigma can improve quality.

See more about Toyota, TQM, and Lean in the next post in this series:

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s build a culture of continuous improvement and psychological safety—together. If you're a leader aiming for lasting change (not just more projects), I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s talk.

Join me for a Lean Healthcare Accelerator Trip to Japan! Learn More

Hi Mark – Your post, and Tracey’s LinkedIn images, wonderfully demonstrate how Toyota is a rare example of a large company whose senor management has long been committed to running the business according to the facts (de facto), which is in contrast to companies whose senior management is committed to running the business according to “rightful entitlement” (de jure). It is heartening to see organizations in which senior managers have been able to accept de facto thinking and routines to guide management decision-making. We all wish there were a lot more of them.

A follow-up comment: de facto is really the essence of TPS and The Toyota Way. They developed various methods and tools over the years that make people face reality so that the facts cannot be avoided, and so that action is taken based on the facts — in all levels of the hierarchy, from worker to president. This also shows a level of caring for the business and its stakeholders that is hard to find in other big companies, not to mention innovation in management practice and leadership. It is remarkable Toyota management has been able to prevent a complete takeover by de jure (which almost happened under former president Hiroshi Okuda).

The inability of large American companies to have any constancy of purpose is really astonishing. Its like they suffer from sort of chronic Attention Deficit.

Many thanks Mark for sharing this valuable & insightful post. For long time I haven’t heard about TQM except in training or Educational programs. I highly believe in TQM and that it’s the big umbrella that all attractive names like 6 sigma, Lean, Kaizen, etc. can fall under it.

Also thanks for consolidating the valuable & comprehensive posts from Tracey Richardson about Quality Circles & Problem Solving here as well.

Wishing you good luck in your trip.

Here is what Tracey shared about Toyota’s articulation of the 7 QC tools on Linkedin.

Comments are closed.