Streaming Player:

Back on the podcast for the sixth time is my friend David Meier, a Lean / TPS consultant who is a former Toyota leader at their plant in Georgetown, Kentucky. As we mentioned in our April episode (#304), he's gotten into what's, perhaps, the most Kentucky of industries… distilling bourbon (and more) at Glenn's Creek Distillery.

Update — His “OCD #5” was named “US Micro Whisky of the Year” in the 2023 edition of the Jim Murray Whiskey Bible. Congrats, Dave!!!

In this episode, there's a lot of bourbon talk, with some Lean concepts thrown in. If you share our interest in Lean and whiskey, then this might be your most favorite episode ever. Of course, if you don't have any interest in bourbon, you might well skip this one.

Here is an article from IISE magazine about David's work:

Helping the whiskey flow, Toyota style

As David will talk about in the podcast:

“Meier started work at Toyota in the 1980s and later became a traveling consultant. During his travels, he began thinking about establishing his own manufacturing-centered business closer to home. After researching his options, he came upon the original Old Crow Distillery that had been shut down since 1985. The 16-acre property had not been maintained since it closed, and Meier purchased the place in 2014.”

I'll visit David and his distillery next week, so I'm sure I'll have more stories and photos.

For a link to this episode, refer people to www.leanblog.org/309.

His Most Recent Appearance:

Topics and Links for this Episode:

- How did you get interested in distilling? Tell us the story about buying the business and getting things back up and running?

- There's lots of competition, long lead times before you can go to market… so why do this?

- Having solutions, versus understanding what's important, what the problems are, what the bottlenecks are…

- How do TPS / Lean principles apply to this business and the process?

- Are there annual cycles of strategy deployment to choose priorities and goals? Are there lessons from Toyota? “It's an area where I'm deficient.” What are needs vs. wants for the business?

- Bourbon usually requires a long value-added aging time in a warehouse… what can you do to reduce lead time in bourbon making? You can't level-load corn growing…

- Is there conventional wisdom, in Lean or whiskey making, that's superstition or proven in fact? Is there always a better way?

- Are you selling consistency or a product that's very different or better each year?

- In the IISE article, you said, “”When I was at Toyota all the Japanese guys would say, all we do is problem-solve,” he said.” — can you elaborate on that?

- “I took a one week class, so I'm an expert?” What's a “master distiller?” What's a “master?” The Japanese say you never achieve mastery no matter how good you get.

- “When you look at that mindset, you realize it's not about the savings. It's about the use of people, their creativity and directing that in a way that (pushes) them to think harder,” he said. – What do you do to be creative and encourage those who work with you to be more creative?

Posts about Suntory and Kaizen, as we discussed:

David's Books:

More Info:

For earlier episodes of my podcast, visit the main Podcast page, which includes information on how to subscribe via RSS, through Android apps, or via Apple Podcasts. You can also subscribe and listen via Stitcher. Please leave us a review and rating!

Thanks for listening!

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

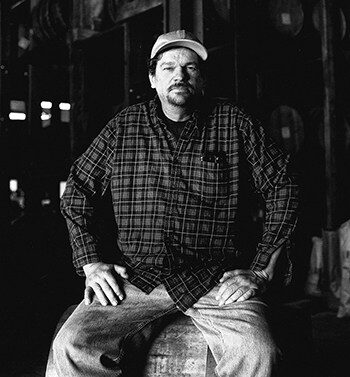

Here is a photo of my recent visit with David… more to come in a future blog post: