Last week, a nurse manager downloaded the free first chapter of my book Lean Hospitals and wrote this message in the contact form:

“Interested to see how the disconnect between management and the staff supervised can be helped. Too many managers refuse to help those they supervise. A growing number have never done the work that they are in charge of getting done. Patients and residents feel it, not healthy. Poor PR. It does get back to the consumer. Difficult to fix at that point.”

In my experience working with many hospitals, her comments resonate with me. Identifying problems like these doesn't mean Lean provides easy solutions for organizational transformation.

It's easy, on the one hand, to say that, in a Lean culture and environment, we'd:

- Not have a disconnect between management and staff

- Managers would help those they supervise and, ideally, would have done the work before

- Worry about providing the best patient care, not just avoiding bad public relations exposure

It's more difficult to help an organization get from here to there… from our current condition to a “Lean culture” — if it's even possible. I'm starting to conclude that some organizations are just too broken (meaning their leadership and their culture are so bad)… and therefore Lean won't really take root unless there are leadership changes at the top (and, even then, it's not going to be easy to change a place with decades of bad habits).

The nurse manager who asked the question used the word “supervised.” I see far too many people in healthcare who are basically not being supervised at all. Of course, a good supervisor isn't a micro-manager and isn't breathing down your neck the whole time. A good supervisor is like a Team Leader at Toyota – they're there to help you when needed (such as the times you pull the andon cord).

To the first point in the list above (eliminating the disconnect), the Lean philosophy, as articulated by Darril Wilburn, a former Toyota leader is:

“It's the responsibility of leadership to provide a system in which people can be successful.”

The Toyota philosophy, as expressed by Jamie Bonini includes engaging and supporting employees:

- Customer first; provide customers with what they want, when they want it, and in the amount they want it

- People are the most valuable resource; Deeply respect, engage, and develop people

- Continuous improvement (kaizen); Engage everyone each and every day

- Shop floor (gemba) focus: Go to where the work is done to find and solve problems

Those are all interconnected ideas. Managers in a Lean culture break down that disconnect between workers and management by getting out of their offices and conference rooms. The leaders at Franciscan Health set a great example for leading everybody in continuous improvement, as I've written about (and shared videos about).

They realize we need to engage people in improvement. It's not enough to judge and blame people after the fact. Leaders need to be supportive and helpful.

A lot of this starts with effective training. Are people really being trained on processes and computer systems — the way things are done here? Far too many hospitals seem to try to “save money” by skimping on training, whether that's onboarding for new staff or training for new computer systems.

When people are struggling to get through the day, patients and staff suffer. Errors and harm are more likely to occur.

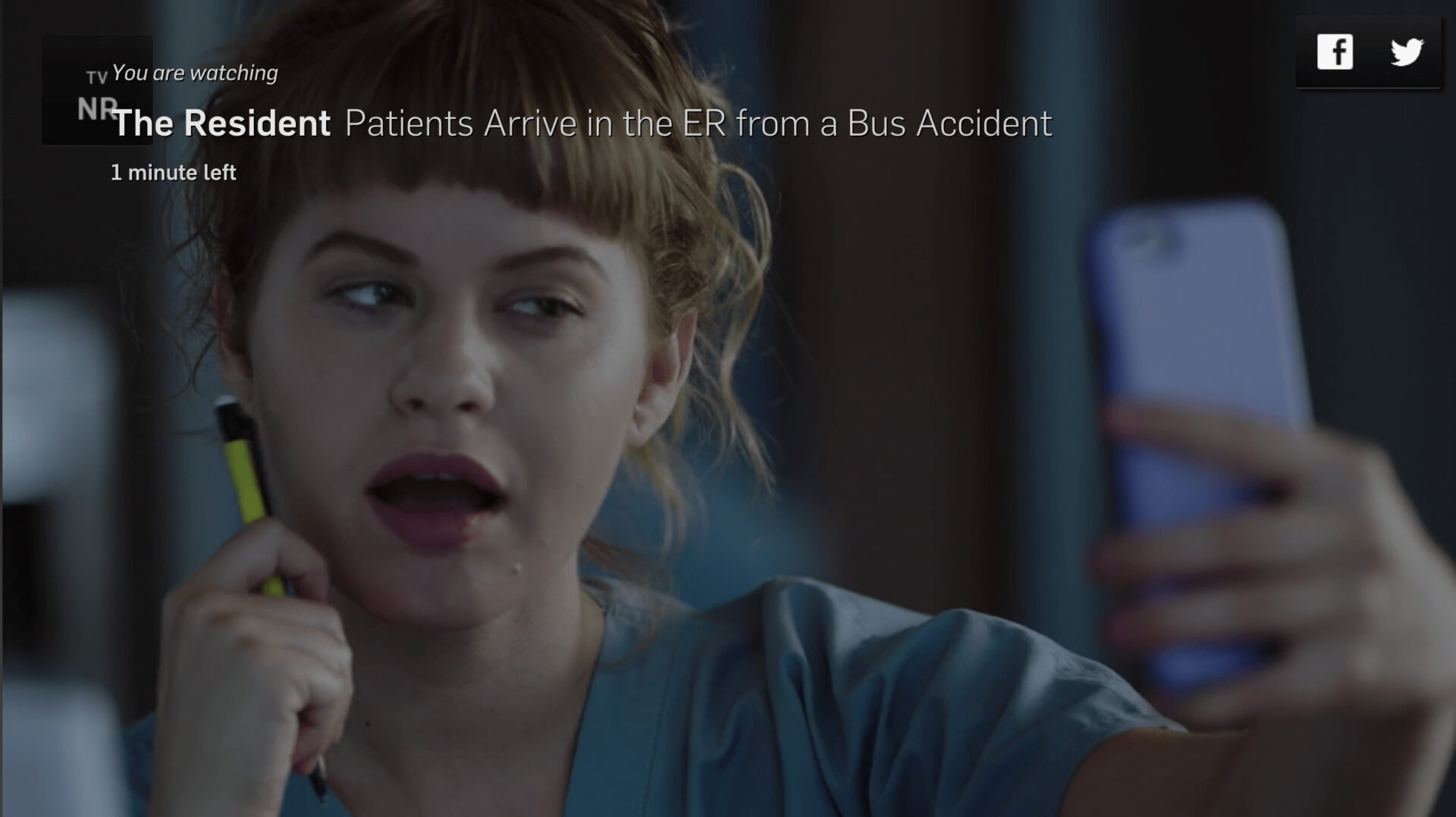

Here is a link to a clip from the Fox series “The Resident.” In the previous episode, the CEO promises revenge against a doctor who signed up to give $2 million in unreimbursed care to a patient… the revenge threat is that she's going to cut staff and he should be “prepared to be woefully understaffed” or something like that.

So, in the next episode, they've fired the experienced emergency department charge nurse for being too expensive. We see the younger, less expensive replacement who doesn't seem to be trained or supervised well on her first day on the job.

She's taking selfies when a doctor basically starts explaining how to triage and she's scribbling notes down. This is not effective, proactive training.

Where is her manager? Selfie nurse isn't being trained. She isn't being supervised.

She's quickly overwhelmed by a flood of patients from a bus accident.

One patient who also walks in with a skateboard injury is told to wait in the waiting room. He ends up just laying on a gurney… long story short, he never gets a wristband (because he was never registered) and gets confused with another patient.

The show “The Resident” is, at times ridiculous and over the top. But, it also rings true in many ways (even if it's exaggerated for dramatic effect… or we could debate how much that's true).

What's the path to a Lean culture for the nurse who downloaded the chapter? There are no easy answers.

The path to improvement that I saw work at my General Motors plant started with getting a new plant manager. This would be equivalent to a hospital site getting a new CEO.

Our new plant manager, Larry Spiegel, who was one of the first GM people trained by Toyota at NUMMI, set a new tone from the top. He spent a lot of time in the gemba, building relationships and listening to people. He made it clear that management was going to stop blaming employees for our poor productivity and quality problems.

Larry articulated how, from his previous experience, this plant was going to become successful… not by changing the workers, but by changing the management system.

It seems that a similar path could work in healthcare.

But, too often, the same CEO with the same bad CEO behavior “sponsors” Lean and hires a few specialists to run projects, certify individuals, and teach some Lean tools.

Is that really a path to Lean? A path to better quality and patient safety?

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

![When Was the Last Time a Leader Around You Admitted They Were Wrong? [Poll]](https://www.leanblog.org/wp-content/uploads/2025/07/Lean-Blog-Post-Cover-Image-2025-07-01T212509.843-238x178.jpg)

![When Was the Last Time a Leader Around You Admitted They Were Wrong? [Poll]](https://www.leanblog.org/wp-content/uploads/2025/07/Lean-Blog-Post-Cover-Image-2025-07-01T212509.843-100x75.jpg)

Hello,

So how to do it on the ground so that it improves if the direction goes in the opposite direction?

What solutions?

Giraud – I’m not sure exactly what you’re asking. Can you please elaborate?

I think we need “translators” who speak both Lean and healthcare. Healthcare is exceptionally unique and cannot be compared to manufacturing or aviation. Human factors engineers are a great resource in this regard.

I can attest that the Nurse Manager role is the toughest leadership role in healthcare. The number of input demand is overwhelming. It is easy to say how they “should” or “should not” be spending their time. But they have to answer to patients, staff, administrators, MD stakeholders and their peers….balancing meetings set by their leaders with wanting to round in their department. We need to do a better job of balancing their workload and reducing their burnout. The Advisory Board has some wonderful resources on this topic. Only then can a culture of implementing best practice exist.

And yes, comparing real world healthcare to any TV drama is like comparing Lean philosophy to robotic perfection…not the most efficient use of words or thought :)

I’m glad you decided to cover this topic, Mark – the not very lean disconnect between staff and their managers.

I’ve given some thought based on my own experiences. One of my observations is the lack of A3 thinking inherent in how some managers review the performance of their staff. Instead of thoughtful diagnosis and treatment of problems, I’ve seen a fair bit of knee jerk conclusions and reactions. A lot of focus on the “who” rather than the “how” and “why”.

As a lean coach in a hospital a few years ago, I was volun-told by my senior manager that I’d be filling in for a colleague who had just left the organization, as kaizen event facilitator for a process I knew little about. I had no history with the process or the team, and expressed concern about that, but got busy preparing.

A short time before the event, I again expressed concern to my manager about expectations. Her response was that I needed to be more independent, in other words, don’t come to her for help.

After the event, which my manager didn’t attend, she shared feedback from a stakeholder who told her the event was a “C” (on the academic grade scale A-F). She clearly wasn’t happy to hear that feedback and let me know, but she did nothing to help either before or after the event, and took no responsibility.

Not a great experience! I left the organization within several months.

Tom – Thanks for the comment. I can understand why that would have been frustrating.