As we get into Lean Startup Week, bear with me please as I continue the heavy focus on the theme of my talk on Friday on “Distinguishing Signal from Noise in Metrics.” I hope my posts on this theme have been interesting and helpful.

The other day, a regular reader commented on a post and made me smile when he wrote the following (I've added links):

“I'm fairly certain I read Donald Wheeler's book on variation after reading one of your previous blog posts. It has helped me try to focus on when I should react and when I shouldn't overreact. From a leadership aspect, I think [“process behavior charts”] helped me understand respect for people better. I realized that I was wasting people's time so thanks for helping me see this waste.”

The main point I'm going to make on Friday is that better understanding variation means wasting less time chasing noise in metrics and wasting less time looking for a simple root cause that probably doesn't exist. It's not just about leaders wasting their own time, but leaders creating a lot of wasted time and motion amongst their employees when they react to the leader asking, “Why was that day/week/month bad?” when that was just “common cause variation” or noise.

I think this also ties into the idea of “respect for people,” as Toyota puts it.

Hear Mark read this post (subscribe to the podcast):

In my talk, I build on this question of Eric's from his first book The Lean Startup:

If we don't encourage people to waste time chasing noise, they can instead spend time on improving the system. See this blog post that touches on what you should do when faced with a system that's not performing as well as you'd like and there's nothing but noise in the metric:

Improving a system that's stable and predictable requires more-systematic, less-reactive methods to understand and improve the system.

Peter Scholtes's The Leader's Handbook

I've been going through the book by the late Peter Scholtes: The Leader's Handbook: Making Things Happen, Getting Things Done. His work builds upon the legendary W. Edwards Deming and Russell Ackoff, among others.

I often quote Scholtes (something also attributed to Peter Senge and others) as saying:

“People don't resist change, they resist being changed.”

I think that's very insightful and that thought has led me to study change management, “motivational interviewing” and other related topics. It turns out that having the right answer and pushing it on others isn't the best strategy for effecting sustainable change. I had to learn those lessons the hard way and I'm still learning.

In the late Russell Ackoff‘s foreword, he calls Scholtes an “educator, not a guru.” Click on any of these book photos for a larger view:

Ackoff has a way with words:

I think it's interesting that Scholtes was a priest before becoming a “management consultant” in the 1980s, per Wikipedia.

See my blog post with video of Ackoff talking about systems:

In Scholtes's introduction, he writes about fads:

People often ask me if Lean is a fad in healthcare. I usually reply that it's only a fad in organizations that are susceptible to fads.

It seems we are at a point with Lean in healthcare where it's no longer the “new” thing – it's something that's now being thrown away by an increasing number of healthcare organizations. I'm not sure what “something new” they are moving on to, other than cost-cutting, which is hardly new. Have some (many?) healthcare leaders given up on Lean because it's difficult? Because it seems not to work for them?

Scholtes was working in the era of Total Quality Management (TQM):

I hope I haven't been guilty of trivializing Lean or its philosophy.

I often hear healthcare leaders, when introduced to the idea of Lean, say things like “Oh we've been doing Lean a long time, we just don't call it that.” That statement usually turns out to be untrue, at least in my assessment.

I think there are many parallels between TQM and Lean, as I wrote about here:

Back to Scholtes, who also has a way with words (such as “roofaraw” and “meaningless twaddle”) when talking about the need to improve systems instead of adding different “fads” (like employee empowerment and continuous improvement) on top of a broken system.

Scholtes says, of course, that the “system is the method by which you achieve results.”

How many of the “failed” Lean healthcare initiatives haven't led to results because leaders or consultants were changing what people did (forcing change) instead of focusing on the system (which is more the domain and responsibility of executives).

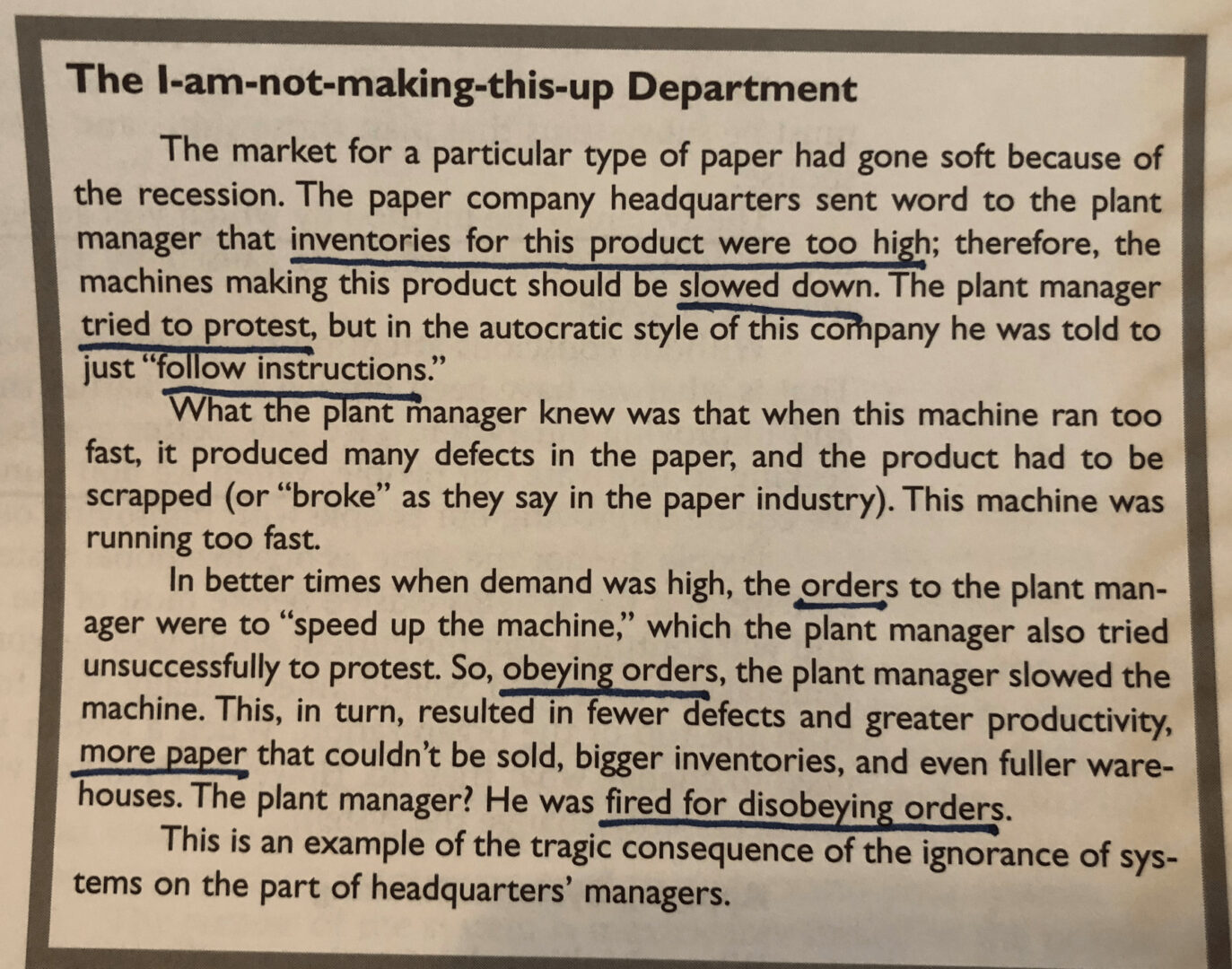

Scholtes tells an amazing story that goes to show how top-down command-and-control approaches can fail and backfire:

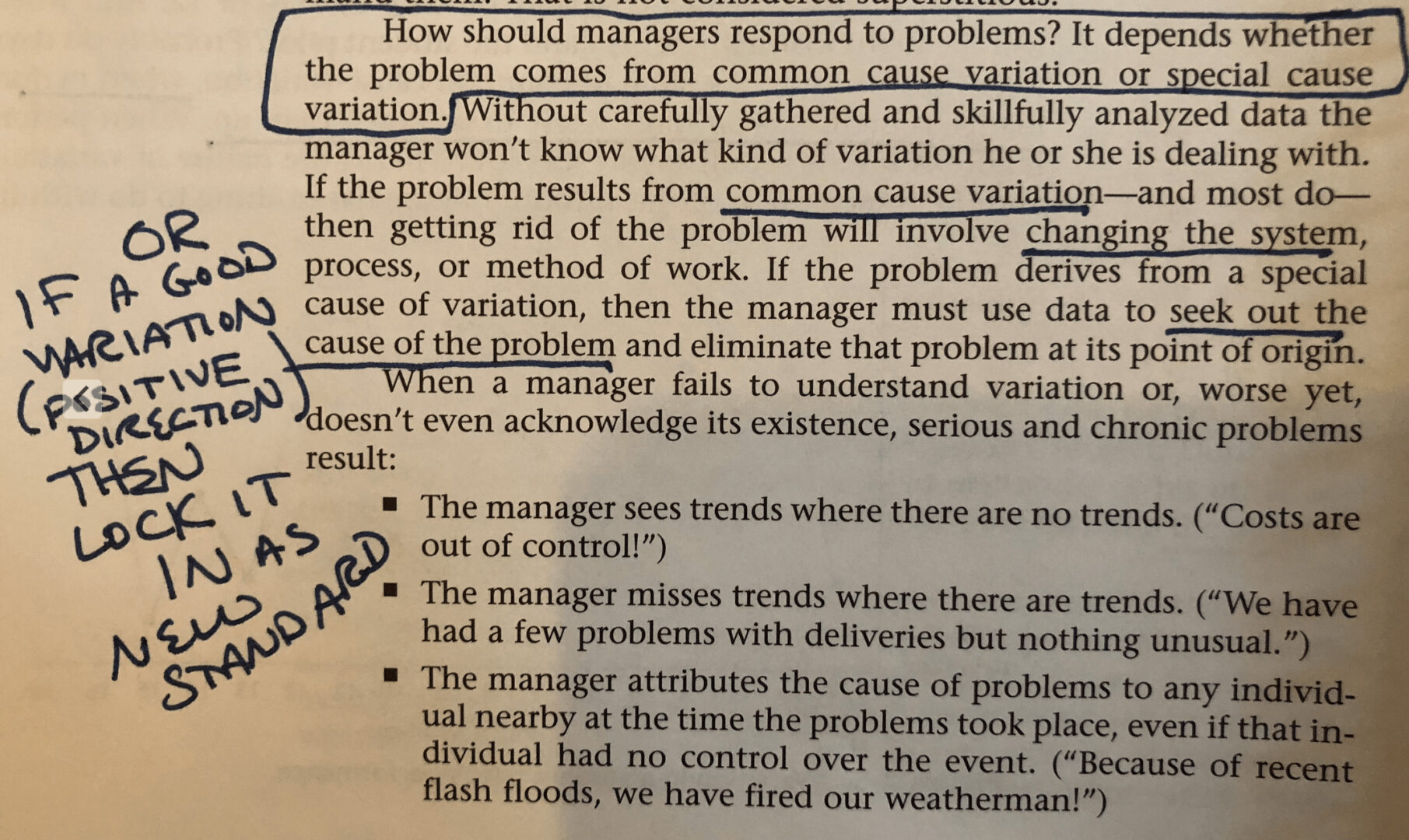

The last excerpt I'll share from that section is back to a point I'll make on Friday…. the need to react differently to common cause variation (noise) than we react to special cause variation (signal):

I'd add that the method (a simple and practical one) for telling the different between common cause and special cause variation (between signal and noise) is “process behavior charts.”

Scholtes writes about seeking out the cause of a problem to get performance back on track.

As I scribbled in the margin, sometimes that variation, that signal, that “out of control data point” is in the positive direction. We should still ask “why?” and look for the cause so we can make sure whatever changed in the system is sustained, if possible.

In my talk on Friday, I hope to give a contemporary version of a talk that stands on the shoulders of these greats…

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s build a culture of continuous improvement and psychological safety—together. If you're a leader aiming for lasting change (not just more projects), I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s talk.

Join me for a Lean Healthcare Accelerator Trip to Japan! Learn More

Mark, I usually read your articles and comments either in your blog or LinkedIn.

The bibliography you recomend is very vast and really helpful (especially the ones concerning variation). However, there is a very interesting book on the same subject (quoted, if I’m no making any confusion here, as reference reading by Mr. Wheeler himself within Understanding Variation), which one I’ve never found any recent mention about. The book is Fourth Generation Management, by Mr. Brian L. Joiner. Have you ever read it? I think it brings a complementary vision on how to deal with and improve in a variable world. Looking forward to hearing from you.

Yes, that’s a great book. Amazon reminds me that I bought it in 2000.

I’ve made reference to it in a number of posts, but should blog about it more.

This is great, Mark. I love the plentiful visuals. We struggle with leadership and front line staff overreacting to “noise’ instead of the “signal”. Working with them to show the difference between common cause and special cause variation. Thanks for the great reminder and insights.

Thanks, Jess. I am glad you are fighting this good fight. I would love to hear about your lessons learned from trying to educate and coach others on this.

This is one of those problems where people don’t realize they have a problem, as Eric Ries put it the other day at Lean Startup Week.

We have to gently open people’s eyes to the existence of a problem first… to help them see the waste and the opportunity.

Comments are closed.