I was invited to give a talk at a gathering of improvement teams and Kaizen Promotion Offices within the NHS in England. It wasn't feasible for me to attend in person… and presenting live over the internet would have meant waking up at 4 am, so we decided that I would record a ten-minute talk for their event.

The video is below… and a transcript and some of their tweets follow.

Updates on “Practicing Lean” – the Book

The idea of “practicing Lean” is, of course, explored in the book I edited (with 15 other contributors) called Practicing Lean. You can buy a paperback or Kindle version through Amazon.

You can also buy an eBook through LeanPub.com, the site where I originally published and updated the in-progress book as it evolved. The audio book version is fully recorded… I just need to finish up the production work on the second half of the book. Learn more about the audio book.

LeanPub.com has always offered a “choose your own price” option. You can use the slider on the page to adjust the price or click to enter a price of your own choosing:

The minimum price used to be set at $3.99 or so and the suggested price was $9.99.

Taking the advice of the team at LeanPub.com… and being willing to run an experiment, I set the minimum price to FREE and raised the suggested price to $11.99.

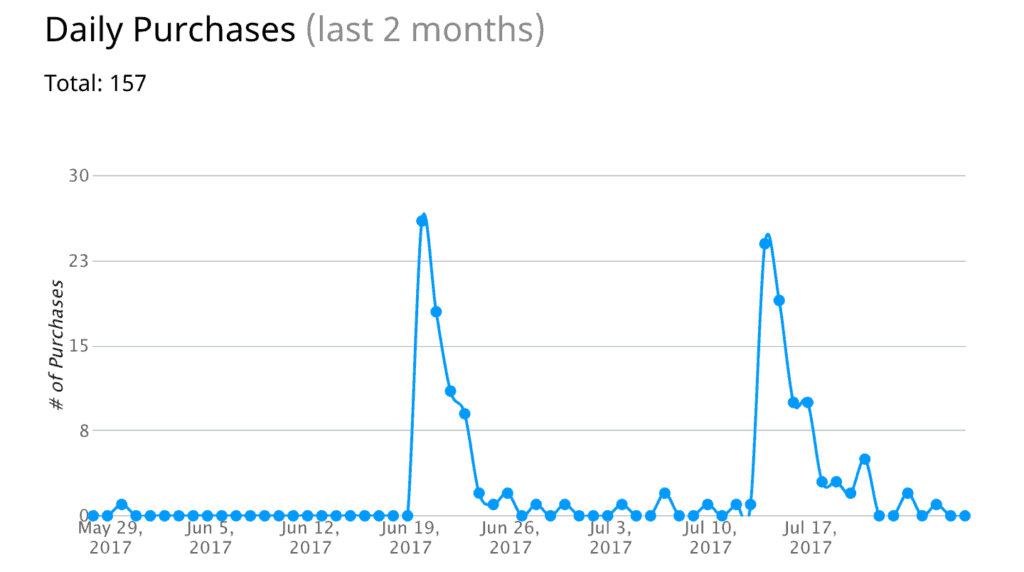

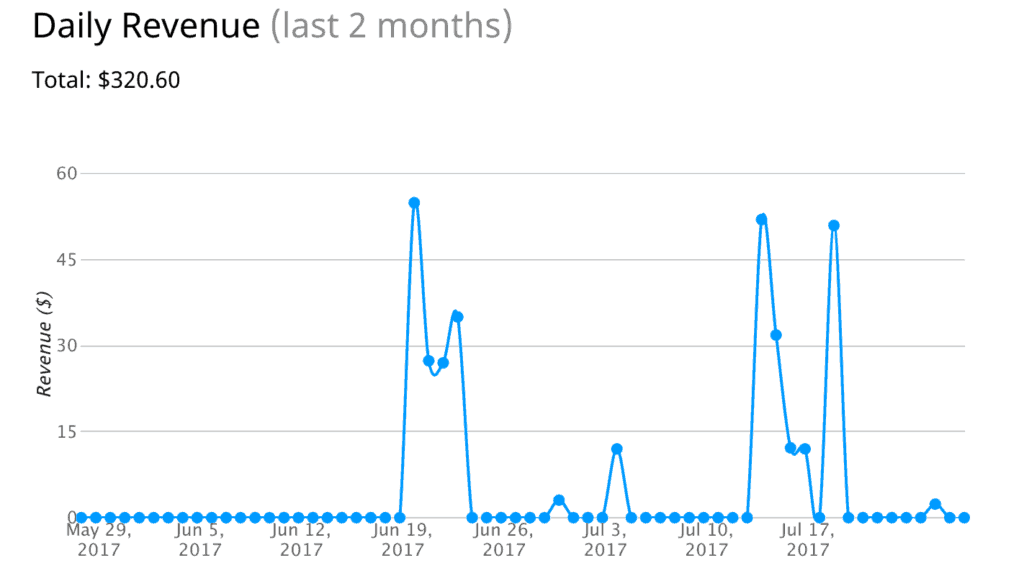

Yes, some people take the free option… but when I've promoted this pricing on social media, I get MORE paid sales and MORE revenue for the Louise H. Batz Patient Safety Foundation, since all proceeds are being donated to them each month.

Here's the data that shows the impact of changing the pricing and doing two social media mentions (leading to a spike teach time):

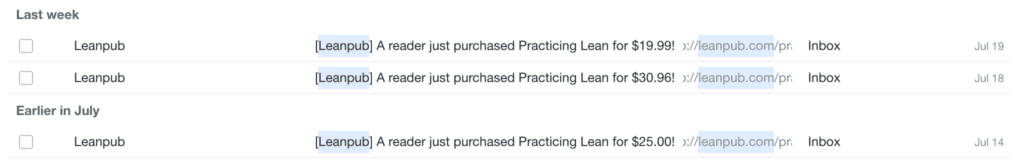

I've also been very pleased that a few buyers have chosen to pay MORE than the suggested price, as much as $30.96. Thank you!!

Tweets About the Talk

Thanks to those who tweeted about the talk:

Huge thanks to @MarkGraban for helping kick off the conference today. True lean knowledge pic.twitter.com/8YWpTGXdSL

— Nick Holding 💙 (@wolvesboy) July 28, 2017

#leanisn'teasy @MarkGraban @LTHTrust @VM_Institute @NHSImprovement #improve356 #nhskaizen pic.twitter.com/gAJxPbZTaa

— KPO@LTHT (@KPOLeeds) July 28, 2017

@MarkGraban addressing the 5 partnership trusts discussing our lean journey @LTHTrust @NHSImprovement @VM_Institute #improve365 #nhskaizen pic.twitter.com/aAeBM333J6

— KPO@LTHT (@KPOLeeds) July 28, 2017

https://twitter.com/LTHTOutpatients/status/890870644568674304

We all start somewhere @MarkGraban @NHSImprovement @LTHTrust pic.twitter.com/WClgQAZwaH

— KPO@LTHT (@KPOLeeds) July 28, 2017

https://twitter.com/ClareWes/status/890871075453763585

@MarkGraban BIG THANK YOU from KPO Leeds, your message was inspiring

— KPO@LTHT (@KPOLeeds) July 28, 2017

Transcript:

Here is an automated transcript from the talk:

Mark Graban: Thank you for letting me be with you here today, at least virtually. I want to thank Julian for the introduction.

My theme today is the idea of practicing lean, which means not just improving the way we do our work and engaging others in improving the way they improve their work. It means having a commitment to improving the way we improve over time.

I love this quote from Tomas Fuller. He is English. He was a 17th century historian who said, “All things are difficult before they are easy.” I think this applies to so many things in life. Any new skill or hobby, sport or musical instrument we might be taking up. I think it also applies to many things we do professionally.

We might also say work is difficult before it gets easy. Here's an example of work being too difficult in a general practitioner setting. This is from a clinic in the United States, a podiatrist who allowed us to shadow him.

We had a nurse from the clinic. We taught the nurse how to do what you see here, a spaghetti diagram, which traces out where the doctor walked. This was not all of the walking across the course of an entire day. This was all of the walking required to treat one patient.

The doctor was running around, searching for gauze, scalpels, freeze spray, what he needed to do his work, to provide care for a patient. It's not that the doctor was disorganized. He worked in four different clinics, four different days of the week, and they were all set up differently.

It's easy to become accustomed to problems and waste in our work. We asked the doctor what could be better in his day, and he shrugged his shoulders and couldn't really think of anything.

When we showed him the spaghetti diagram, this started to make it clear that it didn't need to be this way, that work was more difficult than it needed to be, so we had the opportunity to make it easier.

The team within the clinic had the idea. They could take this cart. It was otherwise being unused. They could set it up with all the supplies that the doctor needed in the course of his day.

They could park this cart outside of the two rooms where he saw patients. It would reduce all of that running around, and patients wouldn't wait as long, and he could quite easily see more patients per day. An example of working smarter, not harder.

The team in the clinic came up with a checklist that they would use to ensure that the cart had been restocked properly before the doctor came in.

It was really fascinating to see, over the course of a couple of days. The doctor went from not seeing the waste, it not bothering him, to then being very bothered by the waste, and then being very appreciative of the solution, the improvement that made his work easier. His next question was, of course, how quickly can I get one of those carts in the other three clinics.

We showed, through direct experience, that lean, at least in this example, was of benefit to him. We can say lean is difficult before it gets easy.

We might ask why is that? If lean principles are really not that complicated, why can it be difficult to change an organization? That's a different question.

We might say, in the context of the language people use, implementing lean is difficult before it gets easy. We might zero in on the word implementing and ask is that really the right word to use in this context.

If lean is about continuous improvement, and this perhaps sounds like a cliché, if it's a journey, there's no end. “Implemented” implies something that we can start and finish, as opposed to something that's ongoing.

My background is engineering. When I got involved in healthcare about 12 years ago, of course we hear the phrase practicing medicine. It made me think about our work with lean.

Here you see pictured a hospital's pathology department in the US figuring out, working together, how to improve their laboratory layout and processes. Here is a team pictured from a different hospital doing what you might call a daily huddle.

At first, all of this is difficult, before it gets easier. If we're getting better over time, we might use a similar language about practicing. Are these people practicing lean?

The word practicing implies that we are learning. We can't improve if we don't learn. We learn by doing. Over time I would add this caveat. We learn by doing most effectively when we have a qualified coach.

This applies not just to lean, but to, let's say, learning golf. If I went and played golf a hundred times without any instruction or any coaching, I might do nothing but develop and reinforce bad habits that might later be unfixable by a coach.

We learn by doing with some reflection, with some assistance. We learn through mistakes, and hopefully we don't repeat the same mistakes over and over again.

If we're embracing the idea of what's either called the PDCA or the PDSA cycles — plan, do, study, adjust — when we plan and when we do something, if we study, and reflect, and think about what we did, what the impact was, did we get the results we predicted?

If not, we can adjust, and go, and hopefully plan and do something differently, as opposed to continually plan, do, plan, do the same things over time. That might not lead to learning, growth, and improvement.

I think it's important to think about the idea of starting somewhere. If we think of a toddler learning how to walk, it's natural that that baby is going to fall in the attempt, in taking their first steps. It would be considered rude and unseemly to laugh at that baby.

If we think of similar situations within lean, if somebody makes mistakes early on in their practice of lean it's probably fair to say we shouldn't laugh at them or mock them, either. We should coach them. We should help them. We can understand why they tried something, it didn't work, and be empathetic, and help coach them through that.

In the idea of starting, I often get this question. Some form of somebody asking, “Which lean tool should I start with?” I don't want to mock somebody for asking that question. I might try to coach them and redirect them to thinking about a different question.

Taiichi Ohno, one of the creators of the Toyota production system, advised people that we should start from need. When somebody asks, “What lean tool should I start with?” I think back to John Shook, from the Lean Enterprise Institute, who asks, “What problem are you trying to solve?”

Taiichi Ohno said we need to look at our most pressing needs and prioritize the problems we need to solve, instead of thinking about which tools we need to use. In healthcare we can think about what matters most — patients, clinicians, anybody working in healthcare. Making care better, making work easier, creating a better environment for everybody.

This practice will help take us from our initial baby steps to, perhaps, running a 5K and running a marathon at some point. We grow. We progress.

We might say engagement is difficult before it get easy. We may struggle as leaders to engage people in improvement. Improvement is difficult before it gets easy. Again, lean is difficult before it gets easy.

Final thought, I love this quote, as well. James M Watkins, “A river cuts through rock, not because of its power, but because of its persistence.” I think of the power of lean, the power of people working in healthcare. Their drive, their passion, their creativity.

We can't expect one-time brilliance to change healthcare. It's that persistence, and working at it, and practicing, and improving through these PDSA cycles.

I would encourage you to think about the practice of lean. I hope that framework is helpful for you.

If you have questions, or if you'd like to reach out, I would love to hear from you. You can email me. You can contact me through Twitter. I would encourage you to maybe even take a look at my website, or contact me that way.

Again, thank you for letting me spend some time with you. I wish I could have been there in person. I love England and the UK. I want to hand things off, though, now to the Leeds KPO team. I want to thank them for the invitation to join you today.

Thanks again to Leeds Teaching Hospitals NHS Trust for inviting me to speak! I hope it was helpful…

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s build a culture of continuous improvement and psychological safety—together. If you're a leader aiming for lasting change (not just more projects), I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s talk.

Join me for a Lean Healthcare Accelerator Trip to Japan! Learn More