Hear Mark read this post — subscribe to Lean Blog Audio

I enjoy “gemba visits” (of sorts) to wineries and vacations often focus on this walking, tasting, and learning.

I usually read the wine column that's in the Wall St. Journal each Saturday, and this one stood out to me:

“Do You Have What It Takes to Be a Sommelier?“

I am friends with a couple of formally trained sommeliers who work in the field in the Dallas / Fort Worth area. They are, to me, experts in wine, but they are at the second level (out of four) in the official sommelier certification system.

I learn a lot from them and, like any good coach, they don't make you feel bad for knowing less than they do.

There are, perhaps, some parallels between the process for passing through the various levels of sommelier training and certification:

- Level I – Introductory

- Level II – Certified Sommelier

- Level III – Advanced Sommelier

- Level IV – Master Sommelier

There is a process of life-long learning and professional advancement along the way, just as you'd have in a Six Sigma (or Lean Six Sigma) “belt” system:

- White Belt

- Green Belt

- Black Belt

- Master Black Belt

There are sometimes additional colors of “belts” (which gets silly at times), but there's a progression, as there also would be in the industry-standard “Lean Certification“:

- Bronze

- Silver

- Gold

Certification can be a controversial topic in the Lean community — see the 91 comments on this post of mine from 2009:

Toyota doesn't offer belts… but they certainly focus on developing employees and leaders. I've heard of them certifying people in certain problem solving or improvement processes, but it's not a “belt” system.

Lifelong learning doesn't necessarily mean labels or certifications. Tracey and Ernie Richardson write about this focus on development in their new book (which I love): The Toyota Engagement Equation.

The Level I somm process involves passing a test. We'd often see the same thing at lower levels of Six Sigma or Lean certification, although there's ideally some practical improvement work that's demonstrated and required for those belts to be granted.

The higher levels of the somm process require the demonstration of deeper expertise as shown through blind tastings, demonstrating and simulating proper wine service in a restaurant setting, etc.

The “Master Sommelier” level is extremely difficult to reach. Per wikipedia:

This exam has a pass rate of less than 1% and it is common for many Sommeliers to make five or more attempts before finally achieving success.

There are currently only 149 people in the WORLD with the Master Sommelier designation.

Both the wine world and the Lean community have people who are new to Lean.

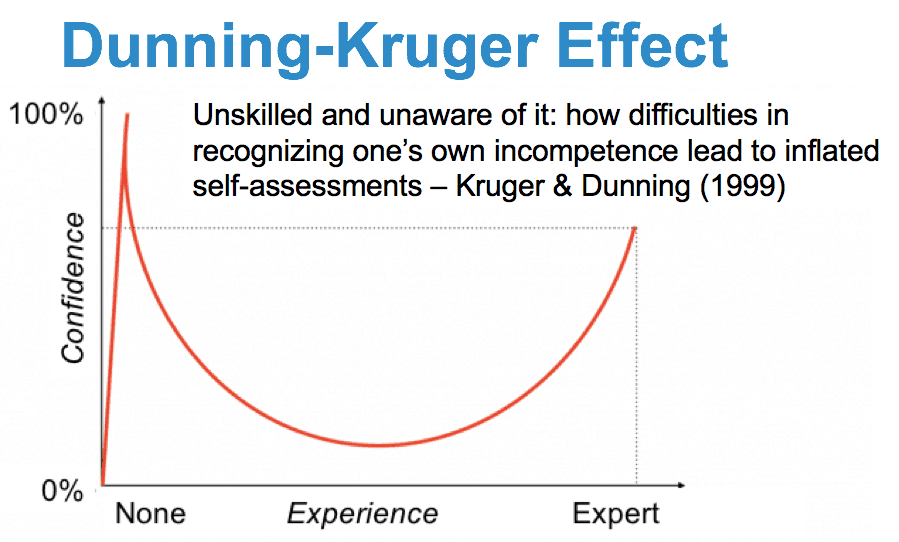

It's pretty common for people to demonstrate the “Dunning-Kruger” effect, where we overestimate our knowledge of something at the beginning of our learning journey:

How often do we hear things like this from somebody who is new to Lean?

- Lean seems so simple

- Lean seems just like a bunch of common sense

- We've been doing Lean for years, we just don't call it that

There's also the temptation to learn something new and then we want to tell everybody about it. I've perhaps been guilty of that in my learning about “Motivational Interviewing” (so much so that I created a web page with some resources and links to what I've been writing as I learn).

But here's the part of the WSJ article that prompted this post:

Aldo Sohm, wine director of Le Bernardin and co-owner of Aldo Sohm Wine Bar in New York, has seen plenty of newly minted somms, whom he considered “almost un-hirable” in their nascent stage. They're often so giddy with knowledge they tend to lecture, not listen to customers. And yet “the true artistry” of the job lies in “being able to listen,” said Mr. Sohm.

Are people sometimes so “giddy” about something new, including Lean, Six Sigma, and Motivational Interviewing that we are guilty of pushing an idea or telling people about new tools whether they are interested or not?

It's a bit ironic, since Motivational Interviewing (MI) emphasizing “evoking” motivations for change instead of “telling” people why they should change. MI also focuses on being careful about giving advice, since it tends to provoke a negative and opposite response.

I think this happens a lot with Lean tools… somebody learns about 5S and they want to go push 5S on others (sometimes with disastrous – or at least annoying – results):

At what point in our practice of Lean do we get better at being able to listen to the needs of the organization? When do we get better at listening to the people we are helping?

“True artistry” seems to be a good term for somebody who is good at this in the context of Lean. MI also emphasizes that coaches should listen more than they speak.

Here's a story from the WSJ about pushing something a somm was perhaps giddy about:

He related the story of a young sommelier who loved a particular red wine from the Jura so much that she persuaded a table of women who liked California wine to try it. The women weren't happy. Mr. Sohm intervened with a big, rich California Pinot Noir from Kosta Browne that the women all loved.

A good somm listens to what the customer likes or desires and finds something that's likely to be a good fit rather than pushing what they like.

The same is true with a good “Lean facilitator” or “change agent?”

The risk of being giddy is that our excitement gets in the way of progress… which is the exact opposite of what we should be trying to do if our primary goal is helping somebody change.

If the goal is to feel good about being an expert, then being giddy might well serve that purpose.

Let's think of a scenario where a manager comes to a Lean facilitator looking for help:

Manager: Hi, we have really been struggling with ED patient flow… our length of stay is too long, patients are leaving without being seen… I'm under a lot of pressure to improve, but I don't know if we can do it.

Facilitator: Great, let's do a SIPOC!

Manager: I don't know what that is, but I have a problem to solve.

Facilitator: Don't rush to solutions, we have to do a SPIOC first! That's always the first thing we have to do. Have you downloaded the new A3 template?? We need to start with the first boxes of the A3. And then we'll do 5S. My instructor said 5S is always a very important first step… I mean after the SIPOC. We have to go slow to go fast as they say!!

Manager: Wait, what now?? I don't think I have time for this… I just have a problem to solve.

It's easy to see where that got off track. Would the facilitator then perhaps blame the manager for not being interested in Lean? Blame them for not being committed to change? Label them as a bad manager who maybe needs to “get off the bus?”

I'd suggest that giddiness is a natural state of progression in the practice of Lean or the learning of anything new. I guess this speaks to the need for good coaches and mentors for those who are “practicing Lean?“

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

Comments from LinkedIn:

Anne Bobb:

Thank you Mark. Great post with some important reminders I fear that the scenario at the end has played out many times in my organization!

J. Er Ralston:

Nice post. Salut!

The last scenario rings home to me. I see this when I talk to people and hear about Lean projects in presentations. I believe John Shock referred to this in the Lean community as modern day “pill-pushers” of Lean tools. “Let’s do 5S because 5S.” I think, Mark you have used the South Park gnome reference, below, to make your point in past blogs, “Phase 1, collect underpants: Phase 2, unsure?: Phase 3, profit.”

People become too focused on which tool to use and less focused on understanding the concerns/problems of the end user and the purpose of the need for change. Learning the tools are important but not in the way most people think. Learning tools should begin to shape your thinking about how to interact with people to help coach them through problems and not to just become an expert in the steps of the tool. What I would like to see more of is a true and genuine curiosity from Lean practitioners on what the end user is experiencing. Learning things like A3, Toyota Kata, and humble inquiry has personally shaped my thinking and approach. However, from my experience approaching a person in a very cold and sterile ways such as define the issue, background, current state, etc. really just shuts down their willingness to work together to solve a problem.

Me: “Hey let’s fill out an A3, do a VSM, an RCA, to determine the future state plan which should include a 5S and some Kamishibai card.”

Manager: “No thanks I’m good. That’s not going to fix my problem”

I sometimes wonder if as a Lean community we come off like the acronym scene in the movie Good Morning Vietnam with Robin Williams (starting40 seconds in).

Let’s avoid the jargon and “Pill-pushing” of Lean but instead use the technique of humble inquiry to truly be curious to understand the situation and what good looks like to the end user. That being said, I would like to hear from the community, “When do you approach and teach people the tools of Lean?” Is it after they see the results of positive change? It is when they are truly curious about how the project results were achieved? Is it in the moment?

Thanks for the comments and the laughs through the videos.

I know I’ve been on this potentially annoying Motivational Interviewing kick, but it’s a really important methodology, I think.

As illustrated in this PDF, the four sequential “processes” of MI are as follows (with my nutshell summary):

1) Engaging – building relationships and trust

2) Focusing – deciding how to narrow in on something to change

3) Evoking – drawing out motivations for change, discussion about confidence in their ability to change

4) Planning – the person you’re helping deciding what to do

Much of Lean practice (and I’ve been guilty of this too) is about jumping into Planning prematurely. We’re telling people what to do until we’ve earned the right to engage with them (having a relationship) and evoking and sparking a pull for change instead of pushing change (or pushing methods).

That’s why I’m spending so much time thinking about and reading about this topic of MI.

Guilty! Oh so guilty!

You’re not alone (see my previous comment).

Science begins and ends in questions. So does the Science of Improvement. It does not begin and end in tools. Typically, subject matter experts have changes that could be tested immediately. Unfortunately, many in the improvement community believe that improvement begins and ends in tools. When a test of change is suggested, too often the subject matter expert is told by the tool expert, “Don’t jump to conclusions.” The job of the “tool expert” is to support the subject matter expert, not get in their way. Add jargon to the tool fixation and you have a perfect storm for wasting time and losing the interest of people whose knowledge is essential to improvement.

Yes… the job of a coach is to help somebody, not to be “right” about which tool to use.

I’m working on an article with a working title of “Why Being Right is the Wrong Strategy for Change.”

Is the “Lean expert” really trying to help the other person or are they happy to “be right” and then complain about how the other people were too dense to go along with their change?

Again, I’ve been guilty of that too.

I’ve been so guilty of being giddy around being a lean facilitator in the past. I laugh at the example you gave between the manager and the facilitator because I could see myself in that role, but I was even worse.

If I theorize what I would have said next as the Facilitator years ago when I first started to practice lean it would have gone something like this.

Facilitator: Don’t worry, I can do the SIPOC for you, I just need a bit of information from you. Oh and the A3, I have it I’ll go ahead and update the first box after I complete the SIPOC. After that then we can do the 5S.

Today, I would try to draw more information out of the Manager. I theorize that I would say some like this. Tell me more about ED patient flow. I’m curious to understand and learn more about the problem we face. You say it’s too long. How long is it taking currently? I’d go on after a response to ask about how long it should take.

Thanks for sharing the page on MI. I’m interested in learning more. I’ve been reading MI Lead for Leadership currently.

Thanks. I’m being “giddy” about MI, I realize.

I have totally seen myself do that before!

Mark how do you reconcile the need to deliver for your “customer” (the company, the individual with a problem) and a change agents duty to set a proper foundation for sustained lean deployment? I feel like a project based approach, while directly fulfilling the needs of top management at that time, can contribute to chaos in a lean deployment. Let’s focus on this, now lets focus on that… SQUIRREL! Employees see problems being solved, but with no cultural change improvements are often backsliding. This differs from an initial deployment to a company with a history of sustained CI, but my question still stands. In some cases we have to satisfy the “customer” AND help the customer understand a path to helping themselves in the future. Which might be things like 5S to drive the fundamentals or hoshin to drive the progression over the whole organization. I’m sure neither managers in that scenario would proclaim ” i have a problem! I need hoshin kanri!” Or “I have a problem, but instead of focusing on the firefight of today I need to create a structured approach to long term problem solving!”

Thoughts?

Danny, thanks for your comment and your honesty!

It’s a difficult position when a customer, being an executive or a client, wants something that perhaps isn’t good for them. What’s professional obligation to try to push back and suggest, for example, “I think just putting 100 boards in units without first doing a pilot or investing in the coaching of managers probably isn’t going to work.”

If principle #1 of “The Toyota Way” is to make decisions based on the long-term, even at the expense of the short-term, should we live that principle? Does that mean risking your job or a client relationship by disagreeing or trying to do what’s really helpful?

Doctors are often put in a bad position when a patient (a customer?) demands pain medication. The doctor might not think that’s the right approach (suggesting physical therapy), but the patient might just go to another doctor… or they might threaten the doctor with a bad patient satisfaction score, which affects their reimbursement.

That’s part of the conversation I started today on LinkedIn about the opioid crisis.

Doing what’s right for the patient, and what’s ethical for the doctor (“first, do no harm”) over the long term comes into conflict with the decision that’s “best” in the short-term.

We can’t TELL executives to do something a different way. But, if they’re not willing to engage us in a conversation… if they don’t ask the “experts” on process improvement about the best ways to improve, should we really be working with them?

There are no easy answers. Thanks for your thought provoking question.