I'm at the 8th annual Lean Healthcare Transformation Summit in Palm Springs, California.

Follow on Twitter using the hashtag #HCSummit2017.

If you're here at the event, please say hello! I love meeting blog readers and podcast listeners.

I'll be adding updates and notes here throughout the day, including John Toussaint's keynote that starts at 8:30 am PT.

Kickoff

Rachel Regan of Catalysis kicked off the event with, of course, a safety briefing (safety first in Lean!)

Kicking off #hcsummit17 is @lean_rregan #lean #safety pic.twitter.com/WNsHzP5eMs

— Mark Graban (@MarkGraban) June 7, 2017

Demographics for the event — 40 US states, 3 Canadian provinces, and 20 countries here

Attendees at #HCsummit17 pic.twitter.com/siGIj1bpq9

— Mark Graban (@MarkGraban) June 7, 2017

John Toussaint Keynote

John is CEO of Catalysis, former CEO of ThedaCare…

About John | Past Posts and Podcasts with John

Understanding Leader Engagement in the Lean Transformation

- There are some good things going on in healthcare – good learning, good experiments, good results

- What I'm interested in is transformation of organizations, not projects

- What's the purpose? What's the problem that needs to be solved?

#HCSummit17 lead off plenary by John Toussaint discussing #Leadership pic.twitter.com/tabQnBhnaQ

— Paul DeChant, MD/MBA (@PaulDeChantMD) June 7, 2017

- We NEED new care delivery systems — the redesign of the work

- What's your process for improvement and innovation? How are you developing your people?

- What's the management system that's required?

- How do leaders need to personally change?

- Where I see the most failure is where leaders aren't making the personal change

It is OUR responsibility to mentor & coach #healthcare leaders. Look in the mirror first!John Toussaint #HCSummit17 pic.twitter.com/y4vRWbQWza

— Rachel Regan (@lean_rregan) June 7, 2017

- The current state of healthcare everywhere in the world is fragile… very difficult problems, unstable environments… but layers of bureaucracy slow down everything

Current state of healthcare via John Toussaint #HCsummit17 pic.twitter.com/Xi4Vw257jz

— Mark Graban (@MarkGraban) June 7, 2017

- Rapid innovation is needed, but we don't have the structures to deliver it

- It's a mess out there

- It's OUR responsibility to figure out the unmet needs of our leaders? Their personal needs? Do we have a process to do that?

- “If I could only get my doctors engaged…” John wants to hand those people a mirror because they need to change the way they're trying to engage people. What are you going to do? What's your process for engagement?

Five Changes Great Healthcare Leaders Make to Develop an Improvement Culture. #HCSummit17 https://t.co/U6PS5uIr9Y

— Steven Shook MD (@StevenShookMD) June 7, 2017

- He asks people, “What was your biggest barrier to being a Lean leader?” Every leader has a different answer. We need to understand what those barriers are for each person.

- 5 leader / CEO behaviors

- Willingness to change, realizing that I have to change for the organization to change

- How much time to spend reflecting on how you're dong? It's usually zero… but they start

- Humility — willingness to go to the Gemba to see and learn

- It's an important behavioral leadership dimension

- Study: CEOs that are humble… their organizations are 3 times better at outcomes metrics (also see Jim Collins Level 5 leader)

- We can practice becoming more humble… asking questions and showing we don't know everything

- Curiosity

- Asking questions. When NUMMI opened, a key interview question for leaders was about curiosity, willingness to identify problems so they can be solved

- Google hires for curiosity and grit (to stick with solving problems)

- It's hard to ask good questions. Can we ask questions that unleash the creativity of our workers? Ask them about how things work and how they think things SHOULD work.

- Perseverance

- Google calls this “grit.” Jim Collins called it “ferocious resolve”

- You need a buddy and a coach to learn this stuff. Practice, coaching… what's what it takes to develop Lean thinking.

- Self-Discipline

- It's hard to get to Gemba every week, etc… all of these things require self-discipline

- Moving away from just fire fighting to really focusing on True North requires self discipline (Susan Erlich, CEO of Zuckerberg SF General Hospital).

- Erlich has a personal A3… titled “Becoming a Model Lean Leader”

- John: Fire fighting takes us off course.

- They are trying to build a leadership system that replaces fire fighting… the chaos starts to resolve

- Willingness to change, realizing that I have to change for the organization to change

A hospital CEO's "leader standard work"… and she's always improving it. #HCsummit17 pic.twitter.com/hpnK1FmJmY

— Mark Graban (@MarkGraban) June 7, 2017

- Eric Dickson, MD, CEO at UMass Memorial – “the biggest barrier to being a Lean leader was myself.” Having to overcome tendencies as a trauma doc to take charge and have answers. He asks people to call him on that behavior when he should really be taking a step back and thinking. “My team helps me stop doing that.”

- John: “Thinking like a trauma doesn't work when leading an organization.” Eric gives people permission to call him on it.

- Don Shilton, CEO at St. Mary's Hospital (Ontario) — it's the safest hospital in Canada

- His goal a few years ago was to make it the safest hospital in Canada, “eliminate patient harm”

- Received that award for safest hospital last year

- He's far surpassed anything we've ever done

- What was Don's barrier to get to that level? “Having the confidence to tackle this and the belief we could pull it off.” “Being willing to fail… to be accepting… was important to us.” Overcoming the fear of failure was key

- Don needed a coach… he was unsure. He needed to learn some things. “Don has become one of the superstars… it's possible.”

- Martin Lund, psychiatric care system (hospitals and clinics) CEO from Denmark

- His barriers: To be faithful to Lean principles… had to stop his old routines, stop coming up with solutions all the time, ask more questions of staff and managers about their ideas for solutions, that was difficult.

- “Listening is not waiting to talk.”

- Marianne Griffiths, a healthcare CEO from the NHS – Western Sussex

- One of 3 trusts to be given “top marks” by inspectors, “Outstanding”

- A plan inspired by an American hospital that engages everybody in solving problems

- 2.5 years into that journey… enable staff, they have the solutions to our problems

- Less hierarchy, everybody has a voice… better care for patients

- What were her barriers to becoming a great Lean leader: Recognizing that I didn't have the leadership know how to get to the destination… 1) what framework do we use? 2) the leadership behaviors that need to change… we needed help and still need help and coaching

- Do you have a process for supporting our executive team members to change their behaviors?

Listening is not waiting to talk. -- John Toussaint at #HCSummit17 Share on XLean leaders must overcome personal barriers… stop fire fighting and starting with solutions. Listen, reflect, learn, coach #HCSummit17 pic.twitter.com/bCU9ISKC6a

— Steven Shook MD (@StevenShookMD) June 7, 2017

Q&A Discussion (also with Kim Barnas)

- Let's run some controlled experiments instead of worrying about failure. That's more easily introduced that way

- Take leaders to learn and see what's possible

- Help them start with a small experiment, try to experience some success

- Start small and try then to spread practices, but keep improving and evolving

- Do you understand the unmet needs of your leaders? Are you intuiting or asking?

- Same question about unmet needs of our patients…

- Kim: “If your Lean management system looks the same after a year, you're not doing your job.”

- Should we be selecting CEOs and senior leaders differently in the future?

- John tries to frame this for Boards. They need to be educated.

- Eric Dickson brought all of his board members and took them to go see (over 100 board members from 11 hospitals).

- Lean healthcare organizations are doing special things… “If you bring somebody in from the outside, a lot of this goes away.” Example of a system bringing in a traditional MBO top-down CEO, this all goes away.

- When somebody comes in from the outside with zero interest in learning to be a different leader, we struggle.

- How is the CEO planning for their successor? You have to present good candidates to the Board, otherwise they will go outside.

- John's path to humility?

- “I was hell on wheels” (said his COO at the time)

- Had to move from being an autocratic leader and needed to become humble (asking questions, mentoring, coaching). “It's really hard to do that, especially the clinicians.” That's why coaching and buddy systems are key.

Learning Session – Winona Health & Toyota

TSSC and Catalysis have a working relationship now (this is very exciting to me!).

Bobby Graves, from TSSC, Marti Bollman and Jan Brosnahan from Winona Health.

Bobby Graves – About TSSC

- January 2016, TSSC approached Catalysis about doing an experiment with a CHVN member

- TSSC is 15 team members – working with small business and non-profit, free service and a way to give back. Bobby has been with Toyota since 1987.

- Toyota has fires, but it's not a daily thing. TSSC can help with daily management… having confidence that things will run well when a leader walks away from the gemba.

- TSSC started in 1992 (after interest generated by the Georgetown plant, The Machine That Change the World and other books). Toyota wanted to share what they do through experience, not just talking about it. TSSC became non-profit in 2011.

- TSSC does a short3- to 5- month experiment and if the client wants to pursue the culture, they'll keep working with them.

- TPS is not just for the shop floor, it's for the whole organization at Toyota.

- TSSC works very closely in the shop floor. Establish a model line and demonstrate TPS

- You cannot do Kaizen unless you're in the shop floor, can't do it from the office

- TPS is an integrated system, an organizational culture

What is TPS? Bobby Graves from Toyota. A culture. An integrated system. Not just for the shop floor. #hcsummit17 pic.twitter.com/6soICfQdu4

— Mark Graban (@MarkGraban) June 7, 2017

- Focused on developing people

- Are we trying to make things easy for people? Employees want a challenge.

- TPS Philosophy

- People are the most valuable resource

- Kaizen (it has to happen every day)

- Focus on the workplace

- Customer first

- The customer is the next process down the line

- Understanding your customer needs is the most important thing

- Technical: Make sure you learn and teach TPS correctly… use the tools and methods correctly

- Management: Motivate and develop people to surface and solve problems

- Build a culture of continuous improvement — EVERY day

- TSS Transformation Model – Model Line Approach

- We can't fix everything… they ask client which problem they want to focus on

- Inch-wide, mile deep

- Top management roles (3 + 1)

- Strong visible TPS commitment — MUST BE HUMBLE

- Understand TPS correctly (principles & details)

- Make problems visible (build culture to expose and solve problems)

- +1: Genchi Genbutsu (go and see at the gemba regularly to grasp the current condition)

- When Toyota walks away, they want you to be able to sustain it.

What did they do at Winona?

Marti – Primary Care Model Cell

- Design & pilot an IDEAL primary care clinic to meet patient needs

- Goals: better quality, capacity, and reduce after hours work for staff

- Did what looks like an A3 — current condition and target condition

- Wanted to reduce no-show rate, improve flow and “operational ability” (provider productivity)

- Goal < 5% no-show rate

- Goal < 30 minute lead time for visit (provider face to face and dictation)

- Started June 2016, worked through December

- Wanted everybody working at a reasonable pace

- Accomplishing goals through real-time problem solving (which means identifying problems in real time)

- “We really believe in being transparent”

- Their improvement experiments include:

- Patients given a form to prioritize and frame up their visit

- “What matters most to you?” in this visit

- If there's too much to address in a 30-minute visit, they'll suggest also scheduling another visit… they prioritize what's needed in this first one

- 30 minute awareness chime

- Automatically goes off every 30 minutes, little sound cue

- Care coordination worksheet

- Identifying complex patients before the visit?

- Andon system – asking for help when needed in real-time

- System for escalation if it's a recurring problem

- What does help look like?

- No-show letters…

- 1st no show – letter from provider

- 2nd no show – letter from VP

- 3rd no show – only get “waiting list” appointments

- “This has been very effective”

- Making it possible to cancel an appointment by text in response to text message appointment reminder… promoting via Facebook that ability to cancel via text

- Better ways to utilize no-show slots… pulling waiting list employees who might be sick as a no-show occurs, if the patient can get there within 10 minutes

- Schedulers “own open slots” via no-show or cancelation… working to keep the slots filled

- One provider each day who is designated for 14 same-day appointments (might overbook by 2 or 3)… patients can be moved from same-day to another provider

- 40 Just Do Its – low hanging fruit identified through observation

- Patients given a form to prioritize and frame up their visit

- “This work is transformational”

- Significant commitment of people and time (especially top management) – can't do this work part-time, improvement is part of how we do our work every day.

- “What's the real problem we are trying to solve?”

- Next steps

- Developing a flow manager role (will work with Toyota on that)

- Standard work for all processes

- Work on level loading (not putting two complex patients back to back, etc.)

Jan – Supply Chain OR Sterile Core Room Project

- Improve ordering and storage processes to eliminate waste

- $3.3M / year spend on inventory, holding about $1M of inventory

- Right supplies in right location, right quantity, right time

- Let staff focus on patient work

- Patient flow, parts flow, information flow… basically did a value stream map

- Selected 38 parts to start with, a replenishment system

- Grasped current condition and problems

- Goals: Reduce inventory, increase availability

- Kanban system – 2-bin system selected

- Created Excel spreadsheet – plan for every part, basically

- Daily usage / consumption rate and pattern (“Gentani“)

- Used 12 months of data to establish average daily usage

- Looked at lead time, how to set safety stock based on max usage

- Total quantity = average daily usage rounded up + quantity to cover lead time + maximum quantity within lead time (safety stock)

- Mark's note: I've done a lot of work like this to set up working Kanban systems for healthcare departments and clinics

- Can't always go by the numbers, sometimes have to “do what makes sense”

- Create labels that had meaning and friendliness (better than before)… not just meaning to supply chain. Front of card has info for staff, back of card has info with supply chain meaning

- Big time savings for the material replenishment team

- Reducing days on hand inventory

- Some DOH is higher because of the case / carton quantity of the item… end up holding more inventory than desired.

- Some items might just be very rarely, but urgently used…

- Staff find it easy to use… other areas are excited for implementation

Toyota (TSSC) helped @winonahealth create a working kanban system. #Lean #hcsummit17 pic.twitter.com/bYRvt6czIG

— Mark Graban (@MarkGraban) June 7, 2017

Matt May Innovation Talk & CEO Panel

I was busy helping moderate a panel of three healthcare CEOs in a discussion on innovation, including Matthew E. May after his talk on the subject.

Hear my podcasts with Matt. Check out his excellent books.

#HCSummit17 what's hard about this? it's the system! pic.twitter.com/uoGtu1Cniv

— Paul DeChant, MD/MBA (@PaulDeChantMD) June 7, 2017

Leaders tell us what stands in their way of innovation #hcsummit17 pic.twitter.com/JJaQeQEj9c

— Rachel Regan (@lean_rregan) June 7, 2017

How best to ask? How do you create the environment for improvement and #innovation? #HCSummit17 @MatthewEMay #lean #kaizen pic.twitter.com/KooY2nkqy7

— Mark Graban (@MarkGraban) June 7, 2017

Matthew May: Our systems are designed to produce a repeatable outcome. When we need better outcomes… #HCSummit17 pic.twitter.com/FPDiiAwihe

— Steven Shook MD (@StevenShookMD) June 7, 2017

https://twitter.com/fmarin_ES/status/872573887787270144

Thanks to Matt and the CEOs for a great discussion!

Terell Stafford

Some of you might know that Dr. John Toussaint loves to play trumpet, especially jazz. His friend, Grammy Award-Winning trumpeter Terell Stafford was here last year to speak to the CEO Forum subset of the Summit. His talk was so well-received that he was invited back to give a talk to the full group.

He started, of course, with some music:

Jazz great @TerellStafford plays, and then talks to #HCSummit17. pic.twitter.com/YJP7UcBLhW

— Mark Graban (@MarkGraban) June 7, 2017

He has the discipline to practice and grow on a DAILY basis.

“I never miss a morning with my maintenance routine,” (30 to 40 minutes) that allows him to keep his playing at a certain level. “A day can't go by without my maintenance routines, or I'm susceptible to injury,” he said.

Then, he does his longer “growth routine,” (60 to 90 minutes) where he looks at his notes from all of the things that didn't go well in maintenance… and that becomes his growth.

The longest routine is the “exploration routine” (maybe 4 to 6 hours) where he might learn new pieces or listen to new recordings. “This is what musicians really want to do.”

These routines are the key to his success in a very creative and improvisational field. I love it.”

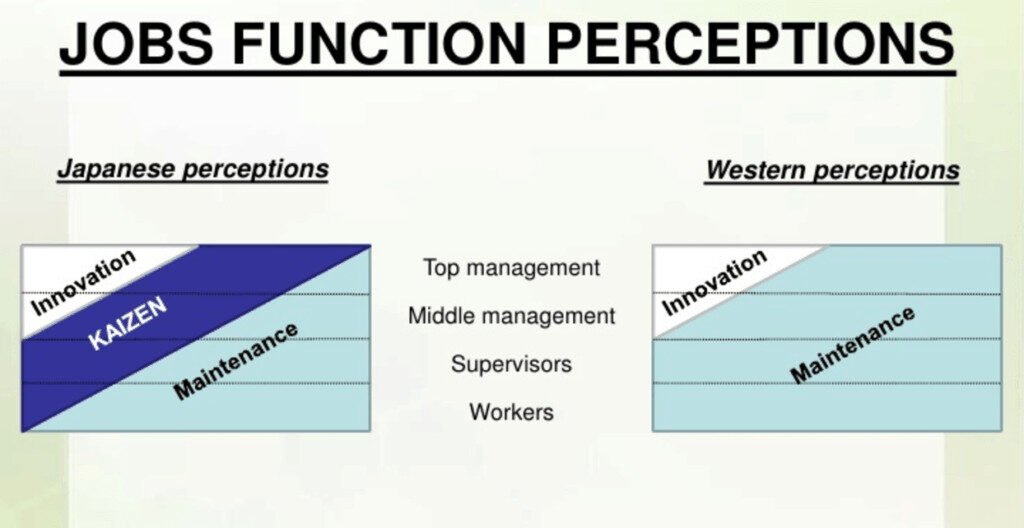

It reminds me of Masaaki Imai and his ideas of maintenance improvement, Kaizen, and innovation:

What would be the equivalent of:

- Maintenance routines

- Growth routines

- Exploration routines

in your day or your week as a Lean facilitator, as a manager, or as an executive?

Is reading LeanBlog.org maintenance, growth, or exploration? :-)

Terell said:

“Every day for me is failure… that's why I have these routines. Failure is a humbling part of learning.”

During Q&A, Terell said that John Toussaint's thoughts on humility and effective listening were really thought provoking, Terell said he wasn't very humble early in his career, but has managed to become more humble over time (partly a function of playing mostly in New York City, where there are many “better musicians”).

This post was updated throughout the day.

More tomorrow for the 2nd and final day of the Summit.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

[…] insights from the conference, you can check out Mark Graban’s posts from the event for both Day 1 and Day 2 and the highlights from Catalysis, or go to the Twitter hashtag […]

[…] insights from the conference, you can check out Mark Graban’s posts from the event for both Day 1 and Day 2 and the highlights from Catalysis, or go to the Twitter hashtag […]