I've gotten to know to know Harry Kenworthy (pictured at left) over the past few years after meeting at a conference (the Northeast L.E.A.N. conference, I believe). The next Northeast L.E.A.N. Conference is October 4 and 5. It's a great event and it's too bad I can't make it this year. I love the folks at GBMP, even though Lean is not an acronym :-)

I've gotten to know to know Harry Kenworthy (pictured at left) over the past few years after meeting at a conference (the Northeast L.E.A.N. conference, I believe). The next Northeast L.E.A.N. Conference is October 4 and 5. It's a great event and it's too bad I can't make it this year. I love the folks at GBMP, even though Lean is not an acronym :-)

You might recall I did a podcast with Harry on Lean in Government back in 2014:

Podcast #198 – Harry Kenworthy, Lean in Government (Local, State, and Federal Levels)

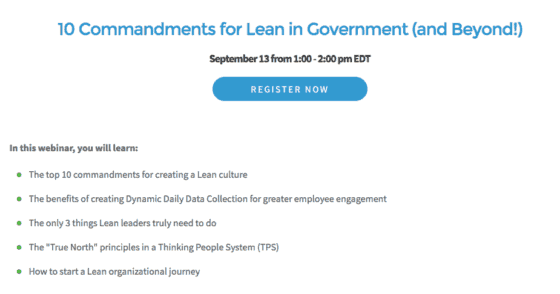

Before I share some of his more recent work, I'm happy to announce that I'll be hosting a free KaiNexus webinar, presented by Harry on September 13. It's free and I think the 10 “commandments” that he'll talk about apply to pretty much any setting… so please attend even if you don't work in government.

Recently, Harry shared some videos produced by the city of Denton, Texas. Denton is only about 45 minutes away from me here in the DFW area. It's the home of the University of North Texas and it's a very fast-growing community. Harry and his consulting firm, QPIC, have been working with them.

Here is Denton's page about Lean.

As we've found in manufacturing, healthcare, and other settings, Lean is a great strategy for managing GROWTH. If an organization is in a shrinking death spiral, like GM or some healthcare organizations, that have been just cutting and laying people off, it's hard to engage people in Lean… they rightfully fear for their jobs.

Lean is supposed to be an alternative layoffs, not a way of driving workforce reduction.

So, when you're growing… waste reduction and process improvement, along with Lean management practices, means productivity improvement and the ability to “do more with the same staff” in a way that provides better service and doesn't overtax employees.

I've worked with hospital labs that are doing 30 to 50% more lab testing each day, with the same staffing levels. It's a calmer workplace because, again, we've empowered people to make their work easier through Kaizen and other methods.

I'm going to write more about them, but Frisco is another example of a high-growth (hypergrowth) North Texas community. Their public library, thanks to Lean, is circulating twice as many books with the same number of employees. Technology has helped, but Lean is a big part of that equation too.

Denton is growing quickly, so, as they say:

“To meet this demand [of a growing population], we intend to have controlled growth in our capabilities by innovating and reinventing ourselves rather than just adding equipment, staff, and layers of bureaucracy. By applying methodologies proven in manufacturing, health care, service industries and even government, LEAN practices draw upon employees to remove redundant and inefficient processes and enhance skills to provide outstanding customer service. This work is rewarding, meaningful, and creates a better community. This is Denton's LEAN Journey.”

Lean isn't just about financial results and customer service. It's about creating a better workplace.

Here are some videos created by Denton.

In their video about the “Five Whys” problem solving method, they emphasize root cause problem solving and creating a more fulfilling workplace:

The “five whys” method is, of course, very helpful. I'm glad Denton is sharing this idea of “the five whys” with their employees and I hope it catches on.

As I've blogged about before, some people mistakenly think “five” is the magic number.

I've also written about how “the five whys” really works best as part of a broader problem solving methodology.

Beyond the Five Whys: Lean and Lean Startup Require a Deeper Dive into Problem-Solving

Back to Denton… they also have a video about 5S, a basic Lean method:

https://www.youtube.com/watch?v=esKwJ52COks

I would try to emphasize that 5S is about more than taking stuff to the dumpster and creating a cleaner work environment.

How does 5S improve productivity and reduce wasted motion and time? Does a 5S-ed work environment in Denton make it easier to see problems before they fester?

I don't mean to nitpick the video, as it's short, but I'd try to focus more on “the why?” What's compelling to employees? What makes them want to participate in this instead of wondering if it's another management fad? I'm sure Harry and his team are helping them work through this.

Their last video is about swim lanes and eliminating waste:

https://www.youtube.com/watch?v=RibXz4uZzR0

As a woman from fleet services says:

“Lean is a culture of continuous improvement which provides opportunities to employees for more meaningful work.”

That's a great summary! Without saying it, I think that definition embeds the idea of “respect for people.”

From the videos, you can tell they have a “Lean Group” and there are “Lean Coaches.” I like that term. When I worked at Honeywell, my job title and certification was called “Lean Expert” and I hated being called “expert.” “Coach” or “facilitator” is a better term.

It's great to see the progress they're making. Maybe I'll have a chance to go and see with my own eyes with Harry sometime.

Here's a link to their summary of results.

There's a heavy focus on cost savings and time savings. Those are often the easiest things to measure, but I hope they're also measuring and tracking safety, quality, staff satisfaction, customer satisfaction and other metrics (as our KaiNexus customers do).

Yes, management (and city leaders, I'm sure) want to see ROI and cost savings… what I've learned through Lean is that the financial impact is just an end result of improving in other ways; it's not the primary and direct goal.

What do you think?

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

![When Was the Last Time a Leader Around You Admitted They Were Wrong? [Poll]](https://www.leanblog.org/wp-content/uploads/2025/07/Lean-Blog-Post-Cover-Image-2025-07-01T212509.843-100x75.jpg)

Mark, I like to think that ROI or financial gains can be the ultimate goal of a lean transformation. However, it should be done assuming a “focus on the process, not the results” mindset.

For me, this means that our ultimate goal is ROI, but we know that in order to achieve that we can’t act on ROI, so we must first focus on customer satisfaction and efficiency (as an example). And for us to achieve that, we need to develop the people.

So my point is, in order to achieve the required ROI, my primary focus will have to be on the people development. When I think of it this way, ROI and respect for people don’t come across as conflicting. Does it make sense for you?

Yes, makes sense and I totally agree. Lean doesn’t focus on “cost cutting,” but lower cost should be an end result.

I’ve written about that idea a lot, including:

https://www.leanblog.org/2016/01/where-do-hospitals-get-the-idea-that-lean-is-only-about-cost-reduction/

https://www.leanblog.org/2011/09/interesting-article-obliquity/

The indirect path, the “oblique” path is often the best way.