A number of you emailed me about this report in the Detroit News. I grew up in Detroit and my first job was as a carrier for the News. Loved ones have received care from the Detroit Medical Center system… not that you'd want to read about problems like this at any hospital:

“Dirty, missing instruments plague DMC surgeries.“

The main photo that accompanies the story is a little girl… appropriate since the patients and their safety are the most important thing here. That's my passion and primary reason for doing this “Lean” work… patient safety, first and foremost.

I don't know much about DMC, and I've never been there. But, I have previously praised them and their former CEO, Mike Duggan, for seeming like a Lean thinker. It seems that the problems at DMC probably occur at other hospitals around the country. What leads to a newspaper investigation and exposé? A employee who came to them? Newspapers don't have the resources to investigation every hospital out there…

This is an extremely long blog post… but reading it might be quicker than reading all of the stories in the series in the Detroit News… but I hope you'll check them out too.

What Allegedly Happened at DMC?

One attempt at a summary of the situation from the News:

“The records show improperly sterilized tools complicated operations from appendectomies and brain surgeries to cleft palate repair and spinal fusions. Patients were kept under anesthesia for up to an hour as staffers replaced instruments. Dozens of operations were canceled at the last minute, some after anesthesia was administered.

At least twice a child's chest or skull was open for surgery when doctors discovered dirty instruments. In January 2015, open-heart surgery for a 7-month-old girl was interrupted at Children's Hospital of Michigan because a tube leading to a bypass machine was clogged with blood from a previous operation.”

Problems like this (and there are many more examples in the Detroit News series), of course, led to frustration… people were trying to “pull the andon cord” to ask for help, if you will.

“We are putting patients at risk frequently and now canceling up to 10 cases this week … promises just aren't cutting it,” Joseph Lelli, chief surgeon at Children's Hospital, wrote in an email to top administrators on June 29, 2015, at least his third warning in six months.

Surgeons, according to emails obtained by the News, were threatening to move cases to other locations due to missing or contaminated instruments.

What are the Causes?

What's the public-facing response to this situation?

The DMC's chief administration officer, Conrad Mallett, acknowledged challenges sterilizing equipment have frustrated doctors and canceled surgeries.

“This is something that has to be fixed,” he said.

Yes, it needs to be fixed. It wasn't getting fixed. Knowing the causes is an important step in problem solving, before getting to solutions. Complex situations like this usually don't have a single, simple root cause. There are many causes that need to be investigated and prioritized. We might have a few main causes of a problem like this.

What does Mallett say the main cause is?

“…the main problem has been a failure to recruit high-quality managers for Central Sterile Processing…”

Whose responsibility is it to solve that systemic problem? I'd say that's the responsibility of senior leaders (and saying so is different than “blaming” them). You're not unfairly blaming senior leaders for systemic problems the way frontline staff might get unfairly blamed for system problems.

Is the problem, more specifically, one of having unfilled manager positions or having “low-quality managers” for Central Sterile Processing (CSP)?

Is it hard for DMC to recruit “high-quality managers” in general or just for CSP?

A second Detroit News article in the series implies it's both:

“[Mallett] said the DMC has had trouble finding and retaining competent managers to supervise the department.”

Maybe competent managers won't come there or stay there because of the environment that's established by senior leaders? Why is there a retention problem? Do managers think the situation there is so bad or somehow unsolvable?

I don't think this problem is unsolvable. It might be hard, but it's solvable… getting to the goal of 100% on-time instrument delivery, with nothing broken, dirty, or missing.

The chief surgeon Lelli, in an email, seems to blame workers, as described by the paper as a situation where “workers routinely misplace instruments or fail to clean them.” I'd suggest the problem is more likely caused by bad process than bad apples.

Or maybe the paper is misrepresenting Lelli's view because it's human nature to blame or scapegoat indviduals.

Mallett adds:

“What we are not is uncaring. What we are not is negligent. What we are is concerned…”

I don't think anyone is accusing them of being uncaring. Is “caring” a strategy and “concern” a countermeasure?

There's most likely a process problem and “standardized work” isn't being followed. A Lean leader would ask “why?” instead of blaming the workers.

What's the Impact?

DMC claims that were no surgical site infections (but they will not release data on infection rates or instrument sterilization error rates). If there are indeed no infections, does that excuse the, ahem, non negligence? Does that mean the standards don't matter? Or that DMC and patients got lucky?

What's the effect of keeping patients under anesthesia longer than necessary? Is that knowable? Is that measurable? It seems one measure of surgical quality would be “Minutes of unnecessary anesthesia time,” as I've always been told that less anesthesia is better than more… meaning it's easier for the patients to recover (not to mention, it's more efficient for surgeons and the hospital).

A 7-month old patient was in surgery hours longer than planned due to blood from a previous patient pouring out of a suction tube, which meant the whole field had to be re-sterilized, causing “significant risk” to the girl. The hospital says they notified the parents of a complication, but the parents claim they didn't know details until being contacted by the paper.

The Blame Game vs. Good Problem Solving

What was the reaction? It sounds like the blame game…

“…administrators quickly identified the sterilization technician who signed off on the tube as clean.

She was disciplined, but the action was overturned after questions were raised about the evidence during a grievance hearing, records show. Sterile workers are represented by four unions at the DMC.”

Did anybody at DMC ask WHY that problem occurred? Did they ask if there was a process problem? Was there any Lean thinking or root cause analysis done?

Where we have blame, we're also likely to have fear. Surgeons say the contamination problems occur more frequently at DMC compared to other hospitals, but they “spoke on the condition of anonymity, fearing job reprisals.”

Inaction often leads to people just giving up, as one surgeon “quit filing complaints more than a year ago because the situation has not improved. Without such documentation, the situations are not addressed and the employees involved cannot be disciplined.” Another asked, “Why bang your head against the wall?”

Why do they keep thinking the right solution is discipline??

Some might blame the union for helping “let employees off easy,” but maybe the union is correct in fighting against blaming individuals in a bad system. Sure, they'll also defend the occasional “bad apple,” but that's not normally the main problem in healthcare (or any workplace).

Dr. Lelli complained to DMC's COO:

“Who has the will to solve this problem that has not been solved in the 11 years I have been at CHM?”

Was it really a lack of will? Or just not knowing how to solve the problem? Why were they trading emails instead of talking about this in person or putting together a team who could follow a Lean problem solving methodolgy?

Did Outsourcing Help?

I guess it was an attempted countermeasure when, In May, DMC outsourced the central sterile operations to a company, Unity HealthTrust of Birmingham, Alabama, that is taking over management without any job losses.

Has it helped? It might be too early to say (because this problem has been around for years, I wouldn't expect a quick and easy solution).

“Two doctors told The News they have not noticed any improvements since the management of sterile processing at the DMC was privatized.”

If it's a case where you have different people managing a bad process the same way, would you expect improvement or better results?

What Does a Former Manager Say? Did Lean Help?

What does a former manager in the CSP department say?

At the DMC, the system's “huge challenges” have persisted for years — and there's been no “prolonged effort” to fix them, contended Laura Cortner, a former director the DMC's Central Sterilization Department.

Was she what DMC would call a “low-quality” manager?

Cortner adds:

“Consultants, experts and all manner of leadership have traveled in and out, with no sustainable improvement to show for the effort… It is a perfect storm. High volume, high patient acuity, entry level-low paid staff who are not self governing and no sustained support from admin,” she wrote in an email.

One of those experts or consultants was an internal Lean manager:

“Victor Bell, DMC lean manager, is reassigned to help fix problems sterilizing equipment.”

The Detroit News does not share what happened, but the problem did not get fixed. One email from September 2014 references a “walkthrough outlining new processes [Bell] predicts will fix problems at sterile processing.” A new manager was hired in CSP a month later.

According to LinkedIn, Bell left DMC in May, 2015 to take a Lean job at another Detroit-area health system.

How did Cortner describe the DMC, ahem, problem solving approach?

“…fire someone … replace … run them in to the ground, blame them, repeat.”

That probably wasn't Victor Bell's approach, as an internal Lean consultant. Was he fighting the good fight against a dysfunctional blame culture?

Cortner blamed the union, when I'd blame bad processes and poor problem solving, as she:

“…wrote to administrators in 2013 that unions are so powerful she was reluctant to discipline workers for dirty or missing equipment unless physicians took photos of the problems.

“We have stopped formally disciplining staff, when we are lacking the substantiating items listed above, because it ends up getting reversed at third steps (or grievance hearings),” Cortner wrote in an email.”

Does disciplining individuals really help when it's a bad process? If you really have a bunch of bad individuals, whose fault is that for hiring them?? It's management's fault. To his credit, the CAO, Mallett, says the unions are not to blame.

The union agrees it's a management problem (that's no surprise), as the SEIU local president said:

Workers want to improve the situation, she said.

“There is a problem with dirty instruments at the DMC,” Robinson said. “To me, it's a management problem.”

Of course workers want to help. They're not uncaring, either.

What Type of Management Problem?

So, at what level is this a “management problem?” Mallett, as a very senior executive, says “managers are to blame.” Is he pointing at himself in the mirror or blaming the managers who work for him? Blaming your employees, instead of taking responsibility, isn't a good look.

Mallett says top executives tried for “years” to fix the problem, but failed. One of them was rewarded for that failure by taking a new job (and a promotion) as a health system president in California. That executive told the paper that DMC meets standards, but could not cite the standards. Data found in emails obtained by the paper says there was a 5% error rate (or “95 percent of instruments were delivered without problems in the month of June 2014.”) Is that good enough?

Again, the former CEO of DMC, Mike Duggan, is now the mayor of Detroit. Duggan has refused to comment, citing the fact that he's been gone since 2012. Fair enough.

But, he was CEO when they consolidated three nearby hospitals' CSP departments into a single department at Detroit Receiving Hospital.

That sounds like traditional cost cutting, looking for efficiencies of scale. A Lean thinker would be cautious about making a move like that, since sterilizing everything in one location would increase lead times for getting instruments back to the operating rooms at the five different hospitals.

As the emails say, it was “intended to streamline the process and doesn't include new hires or extra money for equipment or space.” I wonder if they moved some equipment and people? Did they fire the people at the other two hospitals? Is that what they meant by “streamline” or were they trying to provide better service to the surgeons, ORs, and patients? Did they make sure (REALLY make sure) that Detroit Receiving Hospital would have enough capacity to do all of that work that was being consolidated?

The general public and the average Joe are quick to blame individuals for problems. I guess it's human nature and it's what makes a blame-free Lean culture so powerful and rare.

The reporter uses language talking about “when employees make mistakes.” We're all human. We all make mistakes. Good people will be defeated by a bad system. Management has a responsibility to provide workers (and patients) a good system, a continuously improving system that engages people instead of blaming them.

Another CSP manager is right when she talks about the need for standards:

“In order to move this department forward, we must have standards that we follow,” Lukeysih Hall, the manager of Central Sterile Processing, wrote in a March 2, 2015, email.

It's the manager's job to manage and improve that situation, not just complain about it. The manager needs to be working with employees, not blaming them.

Again, to his credit, Mallett is at least saying the right thing:

“I don't think we are dealing with an employee population that is any more difficult to manage than any other employee population, and you just simply cannot say your employees are the issue,” Mallett said.

He adds:

“This is a process. We are all in it together. Management and employees. The DMC family has got to solve this problem.”

Again, he's right… is there a lack of will or a lack of an improvement method?

It seems their systems are designed to ascribe blame instead of solve problems.

“Like many hospitals, the DMC uses bar code and scanner technology to track instruments. A computer program known as Alex Gold uses the information and is able to trace which technicians cleaned instruments and are responsible for dirty ones.”

Saying “which technicians are responsible” ignores the impact of systems and processes.

The union president is spot on when she says:

“You want employees to do something a certain way? Manage your department and get it done.”

It sounds like there was a lot of discussion… and somebody declared victory prematurely in 2014. Either this was a short-lived gain or it was “happy talk,” as Pascal Dennis calls it.

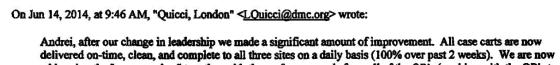

One email claimed things were suddenly fine, with 100% quality for two weeks (click for a larger view):

Hall, that manager who talked about the need for standards, later considered herself a whistle blower, as she felt an obligation to speak up for what's right, even if that put her job at risk.

A Nasty Environment?

She describes being stressed and having her character “discredited” by others. She describes “harassment, disrespect, bullying, and intimidation” and being threatened by the union.

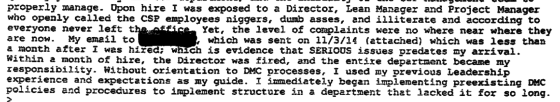

She claims (in an email obtained by the paper) that she was exposed to DMC employees who were racist and disrespectful to CSP employees (warning for the racial slur):

Leaders and managers (including the Lean Manager?) were disparaging the employees? Where was the “Respect for people?“

Hall describes a situation where “all brushes disappeared overnight” and an emergency order had to be placed for replacements. There was a “locker sweep in which we find all 400 brushes,” implying that workers had stolen and hidden them.

Serious question – is that a “people problem” (bad people) or a symptom of a really dysfunctional environment? That action (putting the brushers in lockers) was a choice that people made… but is it an understandable reaction to the environment?

Here's another systemic problem described by Hall:

Who was forcing CSP to put staff in positions they weren't qualified for? Forced to because of unfilled positions?? Forced to in the name of saving money?

A few weeks after Hall's email, “Another new administrator, Thom Michael-Corbit, is brought aboard sterile processing.”

Look at the Employees or the System?

A third article in the series further explores the situation: “Low-paid workers do a high-stakes job.” Low-paid people can effectively do high-stakes jobs if they're working in a properly designed and well managed system. People who are “least educated” (as the article says) can do important work properly if they're working in good processes and the right environment.

The article says “employees can be tempted to skip steps in the cleaning process.”

Why would they skip steps?

Did they have too much work and not enough time? Were there problems with equipment? Unreasonable demands?

“Some instruments may be in short supply, putting pressure on technicians to turn the job around quickly.”

Why are instruments in short supply?? That's a systemic problem that management has to solve

There are usually a ton of reasons other than “they don't care.” Remember, Mallett said they're not uncaring.

And, if employees ARE skipping steps in the process for no good reason, who is supervising them?? That's a management problem.

One other example of a system problem (think of the Olympus scope problem, discussed in the article):

“Even when carefully processed, some surgical instruments have been proven all but impossible to clean.”

One expert points to a systemic fix that's outside of the hospital's control (unless the hospital has the ability and influence to buy instruments that ARE easier to clean… or demand that the manufacturers do better over time):

“Schneiter, the instrument designer, said the FDA should require the industry to prove devices can be cleaned and provide instructions on how to clean and properly sterilize those instruments before being allowed to sell them to health care providers.”

What Happened with Lean?

DMC had what you might call an active “Lean program.” There's a video online about their “Lean Daily Management System” that was being spread around Tenet. I recently did a podcast with Brad White, one of the creators of that LDM system within Tenet and author of a book about it.

Lean Daily Management at the DMC from Detroit Medical Center on Vimeo.

The system CEO, Mullany, says “Lean is a strategy… it's a part of your culture. It's not just a tool, it's about changing the way you think about business. It's about changing the way you push engagement down…”

One of the hospital presidents talks about inverting the organization charge and how the president “reports to the employees.”

Is it too early in their Lean journey to ask why they didn't have more culture change and process improvement in CSP? The above video is about two years old… culture change takes time.

The COO says “a lot of people think Lean is cost cutting… it's not” (I've said the same thing). Huebbers rightly points out that Lean is also about effectiveness and quality.

If the hospital's leaders truly believe that, why did this July 2015 announcement about a new VP for the PMO and Lean only talk about cost and efficiency?

“Bryan has a proven track record of maximizing productivity and achieving cost savings,” said DMC Chief Financial Officer Victor Jordan. “His exceptional strategic mind-set is exactly what the DMC needs to sustain its financial operations and reach its market objectives.”

Bryan Roach had a background in finance, not Lean. According to LinkedIn, he left DMC just a few months after that announcement and took a job as a hospital CFO. What happened?

This Crain's article connects Lean at DMC to cost cutting and layoffs:

Beginning in 2011, the DMC began a review of labor productivity and lean processing at its eight hospitals that cut costs. The reviews led to an unspecified number of layoffs and dozens of other positions left unfilled.

Were daily huddles and tracking metrics (through the LDM approach) not enough to change the culture? Or does it just take more time? Was it all for naught if the main focus was cost cutting and if DMC violated the common “no layoffs due to Lean” principle.

Did leaving positions unfilled cause quality problems like those in CSP?

The Crain's article continues:

Last May, Mullany began daily lean management walks, where administrators walk the floors of DMC hospitals to listen to employees talk about how they would go about reducing costs.

“The benefits are in elimination of waste and inefficiencies, improvement in quality. We are driving out costs at the lowest level,” he said.

Cost, cost, cost, quality, cost. Were they giving lip service to quality while really focusing on cost?? Lean should be BOTH… but with better quality leading to lower cost.

In my Kaizen work, we ask employees:

- How can you make your work easier?

- How can you improve the patient experience and care?

- What problems do you want to solve?

If cost reduction follows, then great. In most organizations, asking about cost doesn't engage or inspire employees.

We see the huddles below. A Lean Daily Management system and board SHOULD have a balanced scorecard of True North metrics (often SQDCM).

Why didn't a “structured approach to solving problems” including the “5 whys,” as described in the video, seem to help in CSP? In the video, we see the artifacts of a Lean management system. We hear leaders saying the right things… but was it really a Lean system?

Lean isn't just about measures… and having employees presenting to leaders at their board… and finding solutions. Leaders need to help provide a system that works. Lean is about empowering front line staff, but they can't fix everything. You hear Toyota people talk about the commitment of leaders to fix the high level system. Frontline staff can't “kaizen” their way to fixing the big picture system.

How can there be “Lean Daily Management” and yet still be so many accusations of blame and punishment instead of problem solving? I realize that becoming a “Lean culture” isn't like flipping a light switch… how many years do you need to be on a Lean journey before the culture of blame goes away?

So What Now?

We have more questions than answers. We're not there at the “gemba” of DMC.

What would you recommend to DMC and their leaders?

Can I do anything to help other than blogging about this? I'm sure me writing about this wouldn't put me in DMC's good graces and that doesn't bother me. I'd be willing to help, but they probably wouldn't ask.

I believe in the mantra of “no problems is a problem.” We have to talk about problems like this so we can figure out how to fix them… and prevent similar problems at other hospitals… not just prevent articles from being written about them?

If your health system doesn't have the problems described by the Detroit News, what can you and your leaders do to prevent those situations from occurring and ending up in your local paper?

If you’re working to build a culture where people feel safe to speak up, solve problems, and improve every day, I’d be glad to help. Let’s talk about how to strengthen Psychological Safety and Continuous Improvement in your organization.

Comment from LinkedIn:

Another LinkedIn comment from a central sterile processing leader:

Here’s the Sunday editorial from the Detroit News:

Editorial: No excuses, no delays in cleaning up DMC

They get a lot of things right… they hit back at Mallett, saying the hospitals WERE negligent.

I disagree with their blaming of the employees… that’s an oversimplification of a complex system.

Yes it has a solution. It’s a management problem not a technical issue.

For workers to “do their jobs correctly,” they need a better culture and environment. I learned at GM (and look at the history at NUMMI) that “bad” workers can suddenly become great with a new style of leadership, namely Lean.

They also say if the outsourcing and new management there doesn’t help, then, “then the sterilization functions should be outsourced to workers who are more accountable.”

The problem is NOT the workers NOR a lack of accountability.

I don’t understand how they reconcile saying Mallett is responsible, and then also blaming workers.

My post caught the eye of the Detroit News managing editor.

I was curious to see if DMC had any Lean jobs posted.

Their jobs/careers website is broken.

“Error

You have encountered a system error. We apologize for the inconvenience. Please click the Back button to try again or (in case of continued problems) click the Home button to return to the beginning.

Error ID:2e841ddb-f853-4441-81c0-f45541d3c0d6”

But the main page has inspirational images of employees. Yes, the work is a “higher calling.” That’s why patients need to be protected!

Does “challenge me” include leaders? Challenge us to properly run CSP?

Always there for patients?

Achieving what?

DMC issued a statement to the community on August 30.

Read it via the Detroit News.

Update:

3 Detroit hospitals lose some Medicare funds over infections

DMC said their instrument sterilization problems didn’t lead to infections. How do they explain the rate of infections (for surgical site infections, etc.) being high enough to be penalized 1% of their CMS payments?

[…] Exposé About Detroit Medical Center, Dirty Surgical Instruments, Dysfunction, and… Lean? Award-winning author and Lean Blogger, Mark Graban analyzes the Detroit News investigation into patient safety and quality failures, including dirty surgical instruments, at Detroit Medical Center. Lean Blog […]

Dear Mark my name is Glenora Harge on April 25th I had a colonoscopy I woke up from the colonoscopy in severe pain didn’t understand what was happening the doctor kept saying discharge Me 6 hour later I was still down in post op as I couldn’t walk without assistance or barely move the pain was so intense I was given no pain medicine I finally asked to be discharged to emergency when they finally took me to the emergency they kept me down there approximately a half an hour or so and sent me up for observation I stayed an observation about 24 hours then I was admitted to a room I was on my back for 4 days had to be assisted to bathroom I had all kind of specialists coming in and out they said I didn’t have a tear then I had a tear then I didn’t have a tear, I’ve was on three different types of antibiotics one doctor told me that they finally cleared up some of the infection, the other doctor told me I didn’t have any infection in fact I was on 3 different antibiotics for 7 days Plus when I was released after the 7 days I was still on two different types of antibiotics for 2 weeks I have asked about this repeatedly what happened was I going septic or what no one could give me any answers, I even asked them could it have been a dirty instruments the doctor told me he didn’t clean colonoscopy instruments (that piss me off) without some of the stupid other stuff he was trying to tell me. after some research I found out they have to be clean by hand, and cannot be cleaned 100% ask had i gotten a dirty colonoscopy instrument the answer was no. The doctor told me I was asking hard questions, I have not had a complete well day since the colonoscopy I have been battling this fatigue and I have not felt well sense they have ran all kinds of tests and they can’t find anything wrong so they say, but all my medical reports is a jumbo of who knows what can’t understand them they have skated around the question but in the meantime I have lost over 25 pounds and still losing weight as of this September I have contacted some lawyers they said I couldn’t prove my case I’m at my wit’s end it has caused me all kind of depression I barely have energy to walk across the street to the store my house is a mess I’m a mess all because of this colonoscopy, they had me believing that this has never happened to anyone before,i so glad I came by this article so I can tell my story thinking I didn’t have any recourse there’s so much more to it. Thank you and have a good day

[…] Exposé About Detroit Medical Center, Dirty Surgical Instruments, Dysfunction, and… Lean? […]

I wonder what has changed in a year?? Has this problem been fixed?

Detroit Medical Center has a new CEO as of early 2017

It sounds like the problem is not completely fixed:

Dirty instruments found at DMC; probe may reopen

But they spent a lot of money trying to fix it:

DMC says $1.2M spent to fix dirty instrument problems

Is this false bravado?

Him not seeing the problem doesn’t mean it’s not there, right?