As a guy who started his career in manufacturing before moving to healthcare in 2005, I don't get many opportunities to visit the “Gemba” at a factory very often anymore. I get to occasionally visit a Toyota plant (in the U.S. or Japan). As I'm getting settled back into the Dallas / Fort Worth (DFW) area, I'm reconnecting with some of the people I know through our local “Lean DFW” network.

One of those Lean DFW people is Rick Foreman, the VP of Lean Development at Federal Heath Sign Co. Federal Heath makes big signs for gas stations, restaurants, hotels, hospitals, and the like. There's metal being cut and bent, stuff being painted, structures being built, and lights being installed and assembled. Rick, pictured at left, is more of a khakis-and-polo-shirt guy (as he was dressed on Friday). Suits and ties exist daily in hospitals but exist mostly in LinkedIn profile photos in manufacturing :-)

We had the chance to meet for a few hours on Friday morning to catch up and talk about their Lean approach at Federal Heath across their different sites. Rick and the folks at Federal Heath have a very strong focus on developing people. As Rick says, “Doing Lean with people, instead of doing it TO them.” They have mentoring and development programs tied to Lean, with leaders at different levels learning from each other in different ways. Their President / CEO is the chief advocate for Lean as a business strategy.

To the Gemba

When we walked the gemba to see where the talk turns into action, there were many visible signs of an active Lean approach. There really wasn't any clutter. We saw standardized tool carts that helped employees eliminate the walking back and forth between a tools area and the sign they are working on. There was an active 5S program (as an ongoing initiative of continuous improvement). It appeared work was taking place in a one-piece flow approach rather than batching up work. The work moves relatively slowly, so it's not like seeing flow in a Toyota factory where the truck moves along every 50 seconds.

But, that's one thing that stood out to me… the custom nature of their work.

In healthcare, people often get defensive when they're just learning about Lean (if they're even trying to learn) and they'll say, “Patients aren't cars!” See my related LinkedIn post on this topic.

Well, duh.

These signs aren't cars, either.

While there's consistent branding on the signs, of course, and they appear to have good contracts with some big brands you would know, you might say “every sign is unique.”

What do we hear in healthcare? “Every patient is unique.”

The implication is to say, “We're different, Lean doesn't work here.” But, Lean is not about building cars, of course. It's about leading people, solving problems, providing value to customers, and improving the organization over the long term.

Rick and Federal Health are using Lean to solve problems that matter to them and their customers. For example, signs flow through the factory much more quickly than before, meaning they can deliver more quickly and more reliably to customers. They aren't building “widgets.” They aren't “cranking out thousands of the same product” every day. They have skilled people doing skilled work.

Hear Mark read this post — subscribe to Lean Blog Audio

So What About the Suggestion Box?

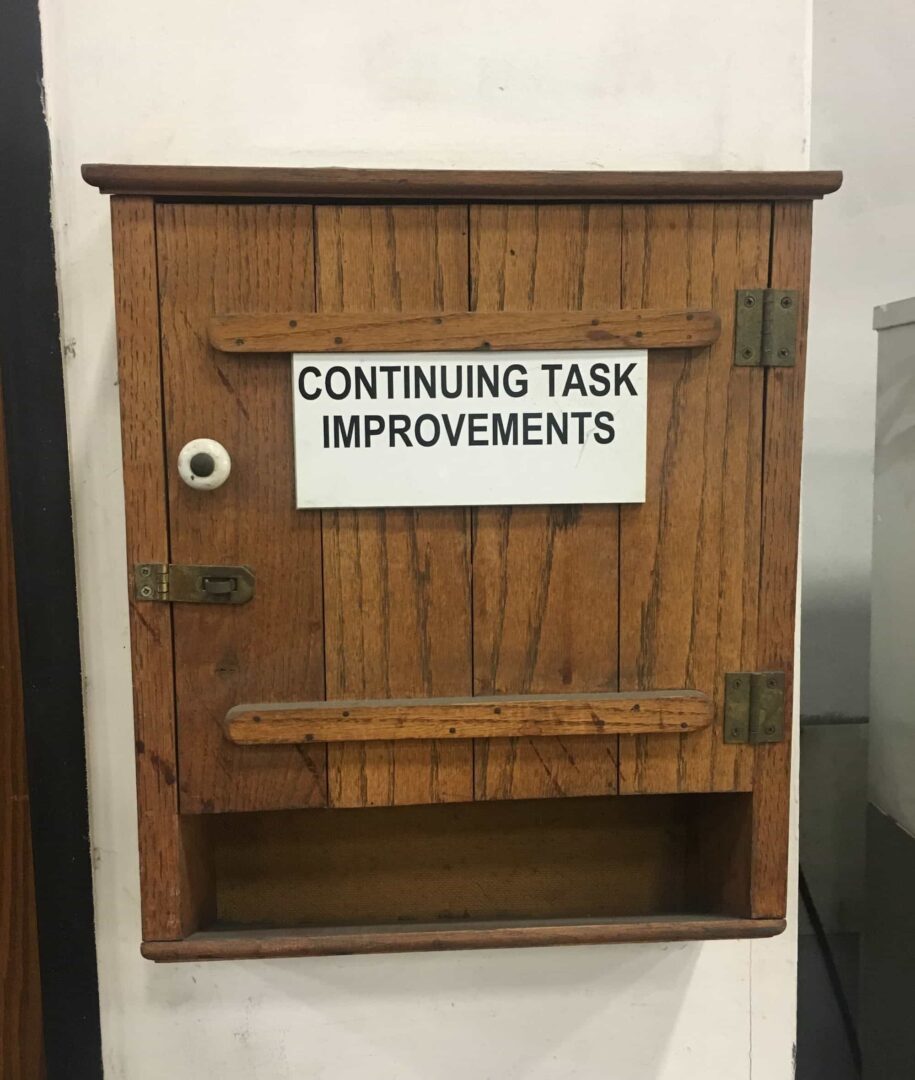

On our way out of the factory, I noticed what looked like a suggestion box (because I notice these things). Rick said it was OK to take pictures and share:

Rick did a double take when I first pointed that out. He said the box pre-dated his time at Federal Health (about 10 years) and he really doesn't see it anymore.

I opened the box (because it wasn't locked) and chuckled when I saw this:

What did we see?

- No suggestions

- Dust

- COBWEBS!!!

It's a perfect illustration about what goes wrong with suggestion box programs.

So why, per the title of this post, was it “OK” that the box was empty and dusty?

It's OK because they have long since moved to another method for tracking ideas and status. Instead of locking suggestions in a box, they:

- Talk about Kaizen on the shop floor

- They post updates on a visible board

- They use a spreadsheet on a shared drive that can be accessed all throughout the company

In some ways, that spreadsheet is like our KaiNexus software, as Rick pointed out, but I would note the software does a lot more than a spreadsheet ever can.

The point is that Kaizen and continuous improvement isn't about the box, the board, or the software — it's about leading and engaging people. It's about talking to people. Soliciting ideas. Talking with people. Working together to implement things.

That's what makes it Lean.

I bet the suggestion box gets removed pretty quickly by Rick or a team member as part of their ongoing 5S work. They don't need the box… because they're doing continuous improvement.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

Awesome photo and related story.

I expect this to become legendary in Lean circles.

Love this! Rick has been a mentor of mine for almost as long as you, Mark. Going on a 8 years or so. Rick is one of the best I’ve ever seen at simultaneously teaching the right spirit of Lean/kaizen/respect for people, while delivering staggering results for the organization. This shouldn’t be a rare thing, but it often can be. Rick is teaching us how coaching, group learning, and simple shopfloor kaizen techniques can add up to huge business improvement.