I want to express my gratitude to Joe Swartz and his colleagues at Franciscan St. Francis Health for hosting our “Kaizen Live!” event. Yesterday was the first full day and everybody (24 attendees) will be back this morning to continue the learning and discussion.

I want to express my gratitude to Joe Swartz and his colleagues at Franciscan St. Francis Health for hosting our “Kaizen Live!” event. Yesterday was the first full day and everybody (24 attendees) will be back this morning to continue the learning and discussion.

The Franciscan story and our other Kaizen experiences are documented in our Healthcare Kaizen books.

I've been sharing quotes and key insights on Twitter, using hashtag #KaizenLive and will continue doing so today.

One of the things I learned (or was reminded of) yesterday is that it requires time and patience to build a culture of continuous improvement. Joe and the Franciscan leaders pretty consistently describe stories in departments that go like this:

- Leaders introduce Kaizen

- Staff shrug and say, “Oh, here's one more thing to do”

- The leaders are persistent… and keep asking for ideas

- The leaders help staff, recognize them…. more consistent effort everyday

- Some staff participate

- Leaders continue their consistent behaviors

- After six months or maybe a year, things really take off. Kaizen has become “the way we think and the way we do things around here.”

Changing the culture in an organization isn't easy. It's not like flipping a light switch.

But, after time, the folks at Franciscan say things like, “Our brains have changed” and “This is just how we think now.”

Kaizen at Franciscan isn't just about solving problems… it's about developing people. They've implemented and documented more than 27,000 improvements since 2007… and there are countless others that staff would admit have not been documented.

It's really special to see this culture in place. The key discussions then, for our attendees, are about how to create this culture. How can you get from here to there? It's easier to see “what good looks like” than it is to get started on that path (and to keep going). If you're willing to take that journey, Joe and I would love to help.

Here are some key tweets from yesterday:

Kickoff and Joe Swartz:

Getting ready for a look at how Kaizen works at the Franciscan Alliance #KaizenLive @MarkGraban @JoeKaizeneer pic.twitter.com/UAZOmi8CYB

— JoeCLucas (@JoeCLucas) April 5, 2016

24 people here for #KaizenLive! Many states and Holland represented. Healthcare and manufacturing. #lean pic.twitter.com/LCnb8jWEiM

— Mark Graban (@MarkGraban) April 5, 2016

Kicking off #kaizenlive is @JoeKaizeneer (black belt) & Sr Martha Ann (green belt) #lean #leansigma pic.twitter.com/qp7plt91Yc

— Mark Graban (@MarkGraban) April 5, 2016

#Kaizen = less stress & more joy at work says @JoeKaizeneer #kaizenlive. Trying to engage all 18,000 people here at @StFrancisHealth

— Mark Graban (@MarkGraban) April 5, 2016

#SixSigma projects only engaged 100 people a year. To change the culture required daily #kaizen approach. #kaizenlive #lean

— Mark Graban (@MarkGraban) April 5, 2016

Helping all people be passionate about improvement is the goal, says @JoeKaizeneer #kaizenlive

— Mark Graban (@MarkGraban) April 5, 2016

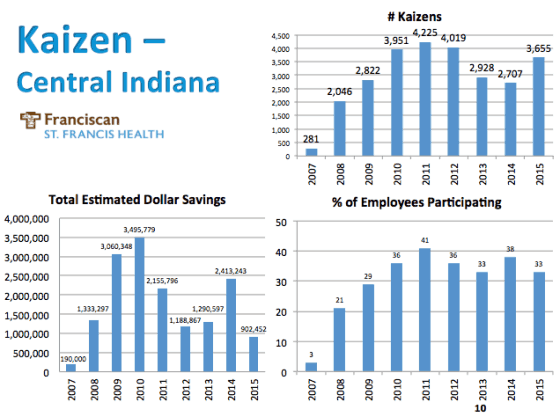

1 #kaizen per person per year implemented on avg says @JoeKaizeneer. So humble about their progress. #kaizen live pic.twitter.com/o3LDHdRi9u

— Mark Graban (@MarkGraban) April 5, 2016

The data he shared:

Last year, 33% of employees participated in #kaizen approach. They'd like that # to be much higher. Peaked at 41% one year. #kaizen live

— Mark Graban (@MarkGraban) April 5, 2016

"Don't walk out of here with any grandiose visions that building a culture of continuous improvement is quick or easy." #kaizenlive

— Mark Graban (@MarkGraban) April 5, 2016

The psychology of change – what happens when you push on people? They push back. Have to try to create pull. #kaizenlive

— Mark Graban (@MarkGraban) April 5, 2016

Engage the early adopters, don't worry so much about the resisters. Those on the fence will probably get on board. #kaizenlive #lean #kaizen

— Mark Graban (@MarkGraban) April 5, 2016

"To develop ppl via #kaizen, you have to start small." Some think it's trivial… But it gets people engaged, then big stuff. #kaizenlive

— Mark Graban (@MarkGraban) April 5, 2016

Having a sense of control via #kaizen helps people accept bigger changes when they come. And they tend to be more innovative. #kaizenlive

— Mark Graban (@MarkGraban) April 5, 2016

#Kaizen is about increasing the rate at which we learn and improve @StFrancisHealth says @JoeKaizeneer. #kaizenlive #leanstartup

— Mark Graban (@MarkGraban) April 5, 2016

The departments with most #kaizen activity tend to have lower turnover, better quality, lower infections. Better measures. #kaizenlive

— Mark Graban (@MarkGraban) April 5, 2016

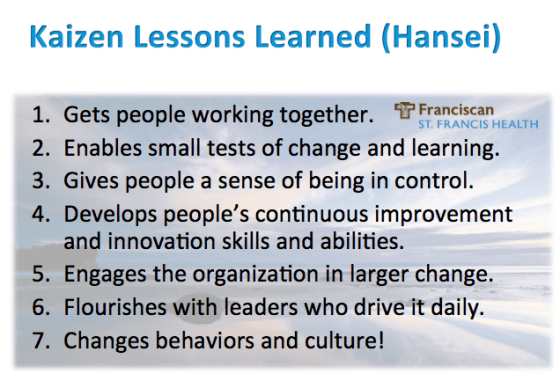

Lessons learned from @JoeKaizeneer #kaizenlive #kaizen #lean pic.twitter.com/l4GeOuAPNy

— Mark Graban (@MarkGraban) April 5, 2016

Joe's lessons learned:

All 27000 #kaizens are searchable in database by all employees across all sites. Share ideas. Spark others. #kaizenlive

— Mark Graban (@MarkGraban) April 5, 2016

Matt Pierce, Nursing Director

Matt Pierce, a nursing director, now talks at #kaizenlive. RN, became black belt, now nursing leader. pic.twitter.com/7P1r6PAlYo

— Mark Graban (@MarkGraban) April 5, 2016

#Kaizenlive – when an RN is facing a struggle in daily work, turn that into a #kaizen opportunity. What hurts? Improve their daily life.

— Mark Graban (@MarkGraban) April 5, 2016

Pierce: #Kaizen doesn't mean every HUC has the stapler in the exact same spot. Sometimes they can do what works for them. #kaizenlive #lean

— Mark Graban (@MarkGraban) April 5, 2016

Endoscopy Director and Nurses, Gemba Visit

Endoscopy leaders & RNs sharing #kaizen lessons before we go visit their unit. #KaizenLive pic.twitter.com/1URmCtlK4S

— Mark Graban (@MarkGraban) April 5, 2016

Endoscopy director: After a few years, our staff's brains are "just wired this way now" for #kaizen. #KaizenLive #Lean

— Mark Graban (@MarkGraban) April 5, 2016

It's not just about saving time, but also investing time in relationships within the team. #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

Most endoscopy #Kaizens start with one person's idea, but "snowballs" with input from team members. Fix what drives you crazy. #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

"When you add new staff, you get new ideas. That leads to more improvement… We want u to have an easier day, not just save $" #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

Endoscopy director does more strategic #kaizens than staff. Vendor management. Building relationships w other departments. #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

Endoscopy – big focus on making work easier by keeping supplies together at point of use. #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

Endo director asks staff "At home, would you store laundry soap in another room?" Small changes matter. #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

Endo: Shift over time from "my boss told me to organize things" to "I choose to help because it affects our bottom line." #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

Endo: #Kaizen is not a one time reorganization. They are constantly reorganizing their layout and supplies to suit needs. #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

Endo: How do you make time for #kaizen? It's a mindset to be aware of the changes your making that are kaizens. #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

Endo director: #Kaizen isn't a flavor of the month. Not all about cost savings. Not about telling employees how to change. #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

Endo: they ask new employees for ideas. "This is not hazing, we want to know what you see and think." #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

~2009 St Francis chose not to have hiring freeze for frontline staff because they had saved the hospital so much $ via #kaizen. #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

Staff love it when executives share their #kaizen improvements widely and give them credit. #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

"When you give your employees power, you have to know when to bite your tongue," says Endo director. #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

You can't empower people and then criticize them for the way they did something if it's fine but not the way you'd do it. #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

Even when a best practice (like timeout checklist) is mandated, staff still have some control over HOW it's implemented. #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

"Instead of being your mother all day long, I can make it easier for employees to do the right thing," says Endo director. #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

Panel Discussion – Franciscan Leaders

#KaizenLive panel question: "I'm a bit afraid to give control to the staff… how do you say 'no' to something when you have to?

— Mark Graban (@MarkGraban) April 5, 2016

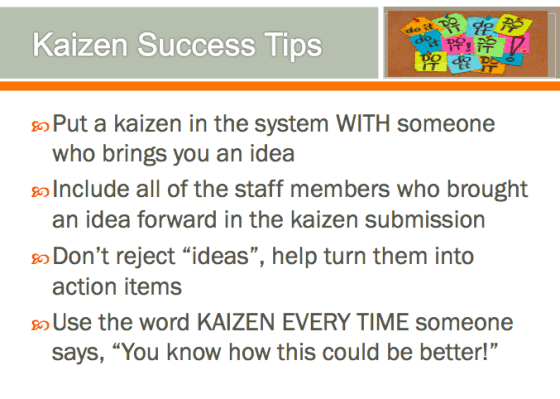

#KaizenLive NICU manager: was coached by @JoeKaizeneer to try as hard as you can to say "yes" to employee ideas, find something that works

— Mark Graban (@MarkGraban) April 5, 2016

#KaizenLive Pharmacy director – if you really can't implement an employee idea (and this is small %), you have to explain WHY you can't

— Mark Graban (@MarkGraban) April 5, 2016

#KaizenLive leaders estimate 80% of staff ideas are ready to implement, 15% require coaching, 5% just can't be done at all — #kaizen #Lean

— Mark Graban (@MarkGraban) April 5, 2016

#KaizenLive NICU RN says only 1 of her 20 #Kaizen ideas couldn't be implemented, but she & other RNs learned about pharmacy process though

— Mark Graban (@MarkGraban) April 5, 2016

#KaizenLive Panel Q: What can you do when directors want to be the one to document #Kaizens, but they stack up because she is bottleneck?

— Mark Graban (@MarkGraban) April 5, 2016

#KaizenLive NICU manager: "You have to believe people want to do their best. Nobody comes to work looking to screw up." #Lean #Deming

— Mark Graban (@MarkGraban) April 5, 2016

#KaizenLive Does the RPh director enter all the employee #kaizens into the Franciscan database? "No, I don't have time for that." Delegates

— Mark Graban (@MarkGraban) April 5, 2016

#KaizenLive Thanks to #kaizens that are rejected due to regulation, the employees now know those regulations far better than before

— Mark Graban (@MarkGraban) April 5, 2016

#KaizenLive Panel Q: How well do you track your $ savings that result from quality focused #kaizens, etc?

— Mark Graban (@MarkGraban) April 5, 2016

#KaizenLive Leaders help employees learn how to calculate savings, cost/benefit analysis. Central group validates claims of BIG savings

— Mark Graban (@MarkGraban) April 5, 2016

#KaizenLive NICU manager: "#Kaizen… the "zen" part is all about how making an improvement makes me feel good."

— Mark Graban (@MarkGraban) April 5, 2016

#KaizenLive Q: How do you make time to improve? A: "You don't have time not to improve" says Pharmacy director

— Mark Graban (@MarkGraban) April 5, 2016

#KaizenLive Q: What did @JoeKaizeneer's team due well to teach others about #kaizen & improvement?

— Mark Graban (@MarkGraban) April 5, 2016

#KaizenLive A: @JoeKaizeneer would share data about departments with most #kaizens. Competitive spirit helped inspire others to do more.

— Mark Graban (@MarkGraban) April 5, 2016

Pharmacy Gemba Visit

#KaizenLive "#Kaizen has given me autonomy and ownership, and knowing my [pharmacy] management will support me."

— Mark Graban (@MarkGraban) April 5, 2016

"It's nice when management asks you what we can do to improve daily operations. 3 improvements/year is realistic expectation." #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

"Documenting a #kaizen is not making a 40 minute presentation." Usually takes 5 min to document it simply. #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

Pharmacy #kaizen: switching from stocking a 1.0 mg capsule only to 0.5 mg only. Pts who need 1.0 dose take 2. #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

Pharmacy #kaizen example: meds that need checked urgently by pharmacist get put on black tray. Visual signal. #KaizenLive #Lean

— Mark Graban (@MarkGraban) April 5, 2016

Pharmacy new tech has done 25 #kaizens in 1st year. Wants "50" badge holder by 2nd year. #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

Previous hospital he worked at didn't have a #kaizen process. Here, he was told about it during orientation. Did 1 in training #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

Common #KaizenLive theme in department visits – #kaizen is rarely a solo act. People collaborate with colleagues, other departments.

— Mark Graban (@MarkGraban) April 5, 2016

Are you a leader who fears your employees will have dumb ideas? "I don't see dumb ideas," says Franciscan pharmacy manager #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

1st reaction to #kaizen is "oh no, another thing to do." "After year, I got used to it. It's a good program," says Pharmacist. #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

"With kaizen, we're not interested in the blame game anymore. We work together to fix things." – pharmacy director #KaizenLive

— Mark Graban (@MarkGraban) April 5, 2016

Perioperative Services Director

#KaizenLive – perioperative services director shares her perspectives pic.twitter.com/yYCTL4r6QH

— Mark Graban (@MarkGraban) April 5, 2016

Her key lessons:

Their “system” means a homegrown web database that they built years ago… “putting into the system” means to help document the idea so it can be searched and shared (as our KaiNexus customers do).

In her fourth bullet point, she was talking about turning complaints into improvement.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s build a culture of continuous improvement and psychological safety—together. If you're a leader aiming for lasting change (not just more projects), I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s talk.

Join me for a Lean Healthcare Accelerator Trip to Japan! Learn More

[…] Wednesday’s blog post was mostly a collection of tweets about the “Kaizen Live!” workshop at Franciscan St. Francis Health. Check it out. Those tweets aren’t repeated here. […]

Comments are closed.