This week, Joe Swartz (pictured at left) and I are running a “Kaizen Live” workshop at his main hospital, Franciscan St. Francis Health.

Today and tomorrow, we're running a 1.5-day workshop where attendees will get to visit departments and hear from leaders who are actively creating a culture of continuous improvement.

Last year, when we did this for the first time, some customers told us that they would have preferred an optional “Kaizen 101” class to be held the day before the workshop. So, listening to that “voice of the customer,” Joe and I offered that yesterday.

For the main workshop, we have 24 attendees… representing hospitals, medical laboratories, consulting, and manufacturing. People are here from across Indiana, and also Minnesota, Ohio, Texas, New Jersey, and The Netherlands.

Yesterday, we had seven people who had signed up for that workshop, joined by a few folks from across the broader Franciscan system who were invited by Joe. I think that experiment, that “small test of change” with that optional pre-class is something we'd continue in the future.

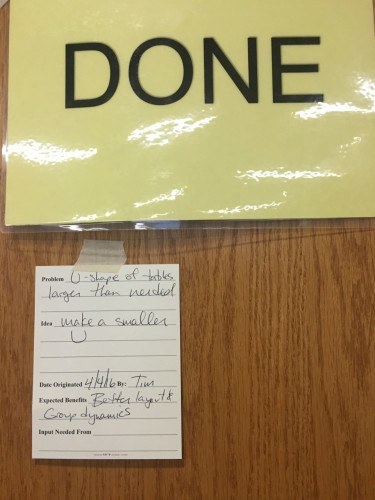

When Joe and I were setting up, the conference room was in a large U-shaped configuration. One early-arriving attendee (a Franciscan process improvement guy who had a long history in manufacturing) pointed out an opportunity to make the U smaller, to be “right sized” for our group.

As they would say at Franciscan, “that's a Kaizen!” Some Franciscan nurses say that in this video (see more videos here).

So, I thanked Tim for the suggestion and we got to work moving tables.

I did fill out a “Kaizen card” that we were going to be using later in the day in an interactive exercise where we practice Kaizen and learn by doing.

Moving the tables was a classic “just do it.” We were empowered. We took action. We made something better (or at least we predicted it would be better). The worst that could have happened was needing to “undo” the table move.

As I told Tim, we didn't need to:

- Fill out a “project charter”

- Form a team or a committee

- Do root cause analysis

- Do an A3

Those methods are all helpful… but not always necessary. We don't have to overcomplicate Kaizen. We were still practicing PDSA on a small scale – Plan, Do, Study, Adjust. It turned out moving the tables was the right decision. It was indeed an improvement.

During the class, I did an experiment… instead of just lecturing about Masaaki Imai's “four goals of Kaizen,” I created a quick exercise.

I had four sheets of paper that small groups were given with the four goals in random order. They were asked to discuss what priority would be best for these goals in a Kaizen setting.

One group got it “right” (per Imai), although it created an interesting discussion. They are pictured below:

- Easier (for employees)

- Better (for customers)

- Faster (prevent delays, make work flow better)

- Cheaper (lower cost is an end result of the other goals)

One participant, from a local hospital, said they key point and learning for her from the day was the need to do less telling and more coaching. She's enthusiastic about change and improvement and often points out what needs changing. That doesn't always engage people very well.

She's going to go back to work and start ASKING more… asking employees what they want or need to fix and asking them what they can help test and implement.

That's the key to a culture of continuous improvement. That and not focusing primarily on cost savings, even though cost is important.

I'll share more on the blog this week… and on Twitter using the hashtag #Kaizen or #KaizenLive.

If you’re working to build a culture where people feel safe to speak up, solve problems, and improve every day, I’d be glad to help. Let’s talk about how to strengthen Psychological Safety and Continuous Improvement in your organization.