A hat tip goes to Brian Buck for sharing this quote via email recently.

Samuel Clemens, aka Mark Twain, was a pithy and wise man.

I didn't remember this quote, but it is attributed to him. It's very appropriate for the type of work we do.

I shared it last Saturday in my “Key Tweets” post, but it's worth discussing here in a separate post, I think.

“Kaizen” is the Japanese word for “good change” and it's usually used in the context of continuous improvement. See this Toyota web page about the term Kaizen, which says:

The philosophy of kaizen is one of Toyota's core values. It means ‘continuous improvement‘. No process can ever be declared perfect but it can always be improved.

Kaizen in practice means that all team members in all parts of the organisation are continuously looking for ways to improve operations, and people at every level in the company support this process of improvement.

Kaizen also requires the setting of clear objectives and targets. It is very much a matter of positive attitude, with the focus on what should be done rather than what can be done.

Many organizations, including those in healthcare, have a stated goal of having a “culture of continuous improvement.” Many, however, fall short of that goal. The reality doesn't line up with the vision. They're far from perfect… which is understandable, as long as they are working on closing that gap between vision and reality.

Hear Mark read this post (Subscribe to the podcast series):

One chapter from the book Lean Thinking (an old book, at this point) is on perfection:

Neither Toyota nor any organization that practices Lean can be perfect. What matters is “the pursuit of perfection,” as the Lexus ad slogan says (being a part of Toyota, of course).

Womack and Jones wrote, in part, about “both approaches” to the pursuit of perfection — radical change (the Japanese word “kaikaku”) and incremental improvement (“kaizen”).

It's a pretty thin chapter on this topic in that book. There's nothing really actionable, except for the idea of improvement being good.

A 1996 Harvard Business Review article by Womack and Jones talks about how to “pursue perfection.”

Again, I think the key is the “pursue” part of the improvement journey.

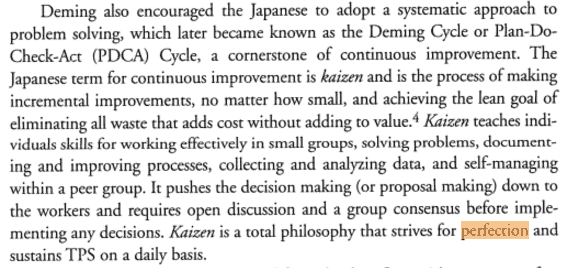

Jeff Liker's book The Toyota Way covers the topic, saying the following (and citing Deming's influence):

“… strives for perfection…” again being the key goal.

Delayed Perfection

What does Twain mean by “delayed perfection?” I see and hear about behavior that illustrates this idea in hospitals all the time.

A team will sit and talk about an idea and possible solutions (instead of going to the gemba or workplace to see the problem and situation first hand). But that's a different topic.

The team might talk and talk… meet and meet… without taking action.

There's either an “analysis paralysis” or a “fear of failure” or something that gets in the way of action.

Being a perfectionist is sometimes our biggest barrier to perfection, if we're not willing to try new things… realizing that some of those new things won't work out well… short-term failures, but learning opportunities that we can learn from.

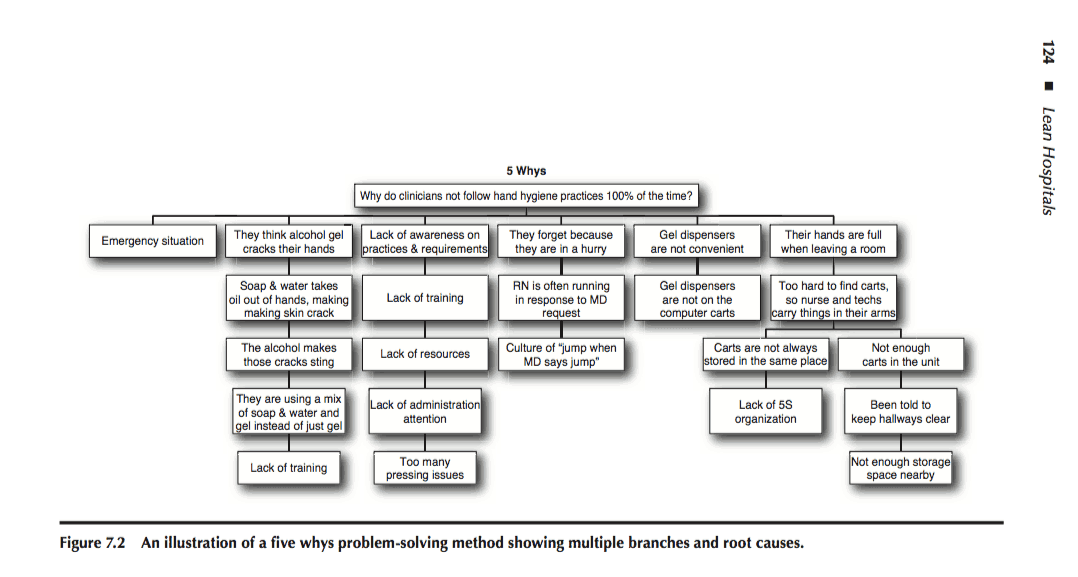

Let's say a team is working on the problem of hand hygiene compliance. As I discuss in Lean Hospitals, there's never just one root cause to a complex problem like this. Therefore, there's no single countermeasure that will “solve” the problem.

See this causal analysis that I coached a hospital through once, asking why hand hygiene practices were not followed 100% of the time (click on the image for a larger view).

A group might look and think that's discouraging… so many causes to address.

But, a culture of continuous improvement would see the potential here. Brainstorming and testing various countermeasures might close the gap a little bit. There's no magic bullet solution that takes us to perfection.

We have to keep working at it. That's Kaizen. That's continuous improvement.

The NICU at Franciscan St. Francis has seen patient / family satisfaction scores “increased from the 45th percentile to the 99th” percentile. They achieved this through hundreds of Kaizen improvements over time.

Are they perfect? Of course not. Neither is Toyota. But those organizations that keep working toward perfection… while accepting they'll never be perfect… those are the organizations that are going to be more successful in the long run.

What do you think?

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.