I am really proud of our KaiNexus customers – the progress they are making and the example they are setting with continuous improvement. They are getting great results, as they report. Beyond safety and quality improvements, cost savings, and other end results, there's a process measure that matters.

I am really proud of our KaiNexus customers – the progress they are making and the example they are setting with continuous improvement. They are getting great results, as they report. Beyond safety and quality improvements, cost savings, and other end results, there's a process measure that matters.

Our customers, if you add up all of their continuous improvement activity, implement 75% of their employee ideas that are submitted through our software.

75!!!%

Most suggestion box systems (paper based or electronic suggestion boxes) typically only have 1 to 3% of ideas get implemented. The rest get rejected. How discouraging is that?

KaiNexus is built around the Kaizen model of continuous improvement. One critical aspect of Kaizen is that managers don't simply accept or reject employee ideas. They have to be coaches… they have to be collaborative to help turn a “bad idea” into some other idea that solves the problem at hand (or at least makes things better).

The Toyota benchmark is 90% implementation rates… but again, that doesn't mean 90% of ideas were awesome to start with. They worked to find SOMETHING to implement.

One of our customers that has made great strides with daily continuous improvement throughout their hospital in the past year is Mary Greeley Medical Center (MGMC) in Ames, Iowa. They've been a KaiNexus customer for a few years, using our software initially to help track improvement events and projects. They have a CEO and other leaders who believe strongly in Kaizen and the need for everybody to be involved in improvement. They have a foundation of quality improvement that includes their state-level Baldrige recognition. Listen to my podcast with their VP of quality Karen Kiel-Rosser as she talks about all of that.

I worked with them on site a year ago as a coach to introduce KaiNexus and a daily Kaizen model into two pilot units. From that initial experience, they took it from there. Karen and their continuous improvement coordinator, Ron Smith, helped spread Kaizen practices (and our KaiNexus software) across the entire hospital in a very systematic way.

You can hear Karen and Ron tell more about their story in a webinar they are presenting tomorrow presented, via KaiNexus. I'll be playing the role of host. See the recording below…

They have a very compelling story. I saw them give a version of this presentation at our KaiNexus User Conference back in October.

Some highlights and key topics that you'll hear about tomorrow:

- Why every employee there has two jobs: to do the work and help improve the work

- How MGMC's leadership commitment to improvement (including their board) was critically important… and what happened next

- How leaders were engaged through action, not just training

- How they identified the most important “key work processes” for defining standardized work

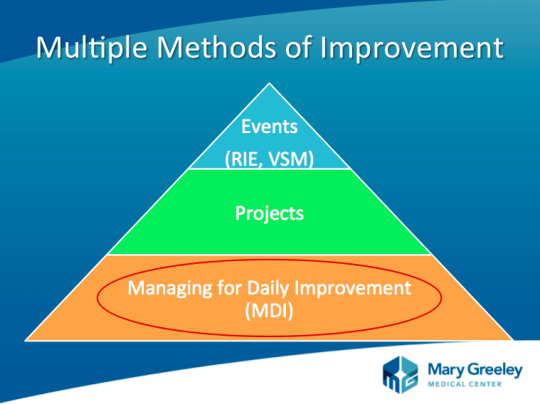

- How MGMC has combined events, projects, and “managing for daily improvement” (MDI)

They will also answer a key question:

“How do we enable and spread improvement in an organization?”

And also:

“How do we share improvement efforts and learn from others?”

Here is the recording:

View more of our webinars here.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation: