I've been studying and working with Lean for 20 years now and I love Lean because I'm still learning and getting better at this craft. I love seeing other people get excited about Lean when it's new to them, when they see the potential for improvement and the power of Lean.

But, sometimes people get excited about things that aren't really Lean.

One example of something that makes me cringe sometimes is talk about “visuals.” People sometimes point at charts or metrics on the wall and want to celebrate having visuals. Yeah, visuals! It's good to measure performance, but that's not necessarily “visual management.” I've seen some folks who seem to think that charts and metrics are the only type of visual management… but that's not really true.

Let's say there's a sign that instructs patients to remember to bring their insurance card, but it's posted too far into the process to be helpful (as I wrote about here). OK, that's a visual. But it's not visual management. It's nothing to celebrate if it's a poorly designed countermeasure that didn't solve a problem that's part of a bad system.

Or, there's a sign telling staff to be careful and not forget something or not make a certain mistake. Hospitals love putting up signs like this, even before Lean. Yeah, a visual! Is that really worth celebrating? Is that really Lean? Instead of celebrating the visual, a Lean thinker would probably work on improving the system in some way to help prevent errors.

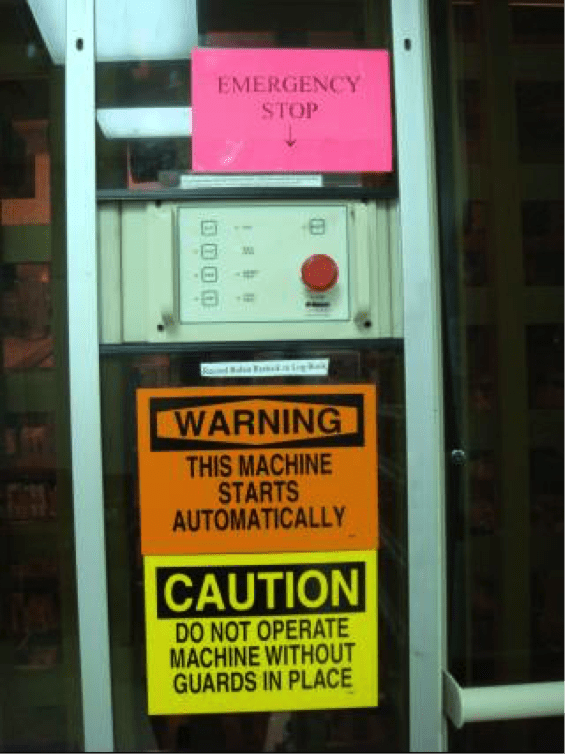

It's not visual management if you're not managing the problem you see visually! Share on XFor example, this sign is a “visual” but it's not a good example of error proofing (on some equipment in an anatomic pathology lab):

My friend Jon Miller shares an example of an unhelpful visual and has a great saying:

Labeling and signage alone are about as effective in preventing accidents as fences are in preventing birds from flying over them.

He calls the shower hot water warning a “visual control,” but I'd argue it's just a “visual.” The presence of the sign neither manages nor controls anything!

Hear Mark read this post (learn more and subscribe):

Here's the Key to Visual Management:

To me, the core of visual management is captured in this statement from Fujio Cho, now the honorary chairman of Toyota:

“Know normal from abnormal… right now!”

If the “visual” isn't helping accomplish that goal, it's probably not visual management. Visual management has two parts – the visual (something you see) and the management (the action you take based on the visual). Why do we have to manage the visual abnormality? To get better results.

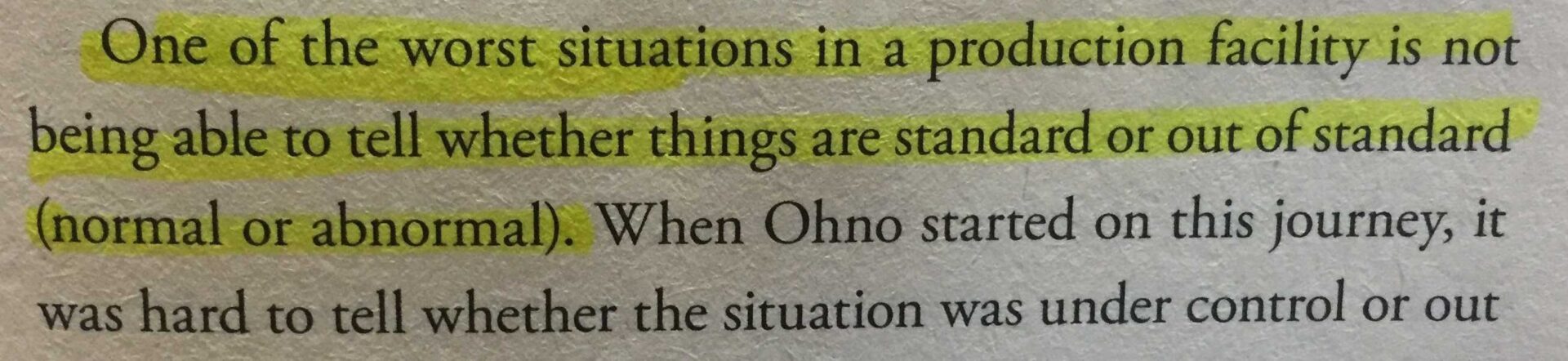

Here's a variation of that Cho quote from the outstanding new book Management Lessons from Taiichi Ohno: What Every Leader Can Learn from the Man who Invented the Toyota Production System:

So, back to hospital settings, look at this example of what somebody might celebrate as a visual (there are three of them!)

Would somebody actually SEE if the pharmacy machine were being operated without the guards being in place? Would you see this and immediately to be able to manage it? Maybe or probably not. To a Lean thinker, the machine should be error proofed so it cannot be operated with the guards removed.

Factories and hospitals normally have some form of charts and metrics on the wall. That doesn't mean they are practicing Lean and those charts aren't necessarily visual management. If the charts show monthly averages that lag a month or two behind, does that help you see the difference between normal and abnormal right now? Probably not.

As charts and metrics get closer to being real time (daily or hourly metrics), they get closer to being visual management. But, the best visual management gives a visual signal that unmistakable and immediate.

Look at a Toyota plant (or any modern car factory). They have painted lines on the floor of the assembly line that indicate if the job cycle has fallen behind (or is running too far ahead, which might be bad, as well). You can see (on the LEI website) the Lean Lexicon description and illustration of what's called a “Fixed-Position Stop System.” If somebody pulls the andon cord, indicating a problem or a concern, then the line stops if the vehicle gets to the final line that's painted on the ground before the problem is resolved.

The lines can also show if there's certain work that should be completed by the 30-second mark, the visual position of the vehicle can show you there's a problem… the work has fallen behind. It's abnormal. You see it immediately (if you're looking).

Supervisors and the team don't have to wait for some sort of hourly or daily metric to be updated.

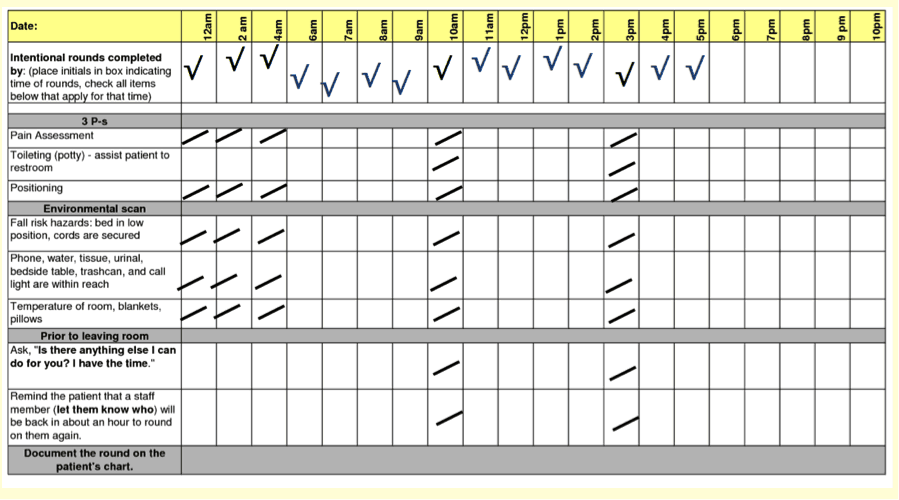

In hospitals, leaders are often concerned if hourly rounding is happening as it should. As I wrote about here, a department might keep an hourly check sheet that shows if hourly rounding occurred each hour. That check sheet is a form of visual management, as you can walk by and see if there are missing checkmarks for an hour. But, the check sheet can make it hard to see the difference between normal and abnormal from a distance.

So, we might use clocks like these that show a real-time view of whether or not hourly rounding is occurring.

The clock is a visual. It's only “visual management” if somebody sees the abnormal situation (a white clock face that indicates that it's been more than 60 minutes since rounding, or it's possibly somebody didn't reset the clock). When management reacts (by asking why instead of yelling or blaming), then that's visual management.

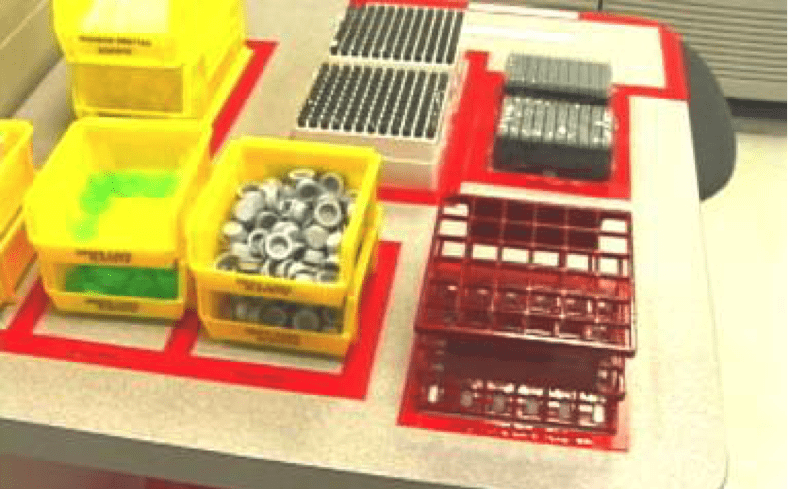

5S can be a form of visual management. Let's say we have a taped outline that shows where a rack full of completed blood specimens should be placed. If it's sitting in the wrong place, there's a visual that shows an abnormal condition. Then, what happens? If nothing, then it's not visual management.

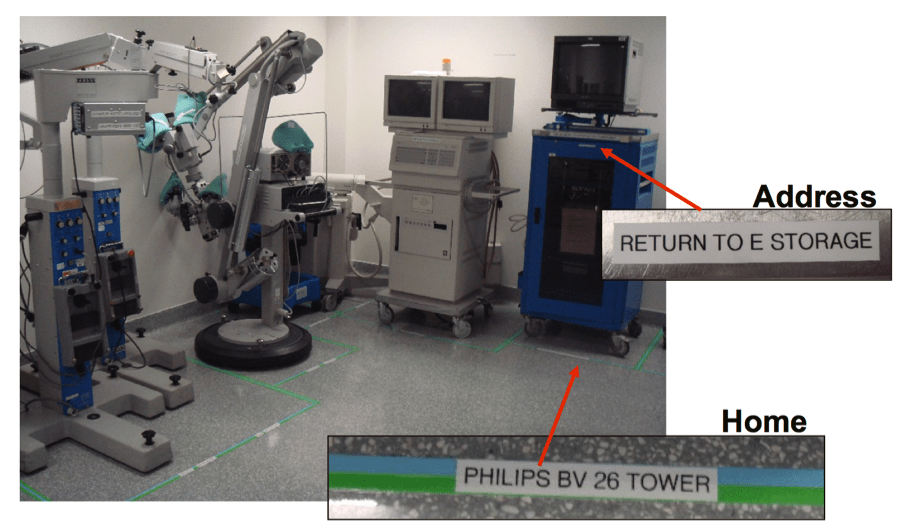

In this next scenario, there's a visual (hard to see) that says that spot on the floor is supposed to be the parking spot for the Philps BV 26 Tower. And that label shows it supposed to be kept in E Storage. Could the visual be better, to make abnormal more apparent? Yes, definitely. There could be a big sign with a picture of the machine hanging on the wall above its spot, making it easier to see what's missing or if the wrong thing is parked there.

And, if something's abnormal, who is managing the visual?

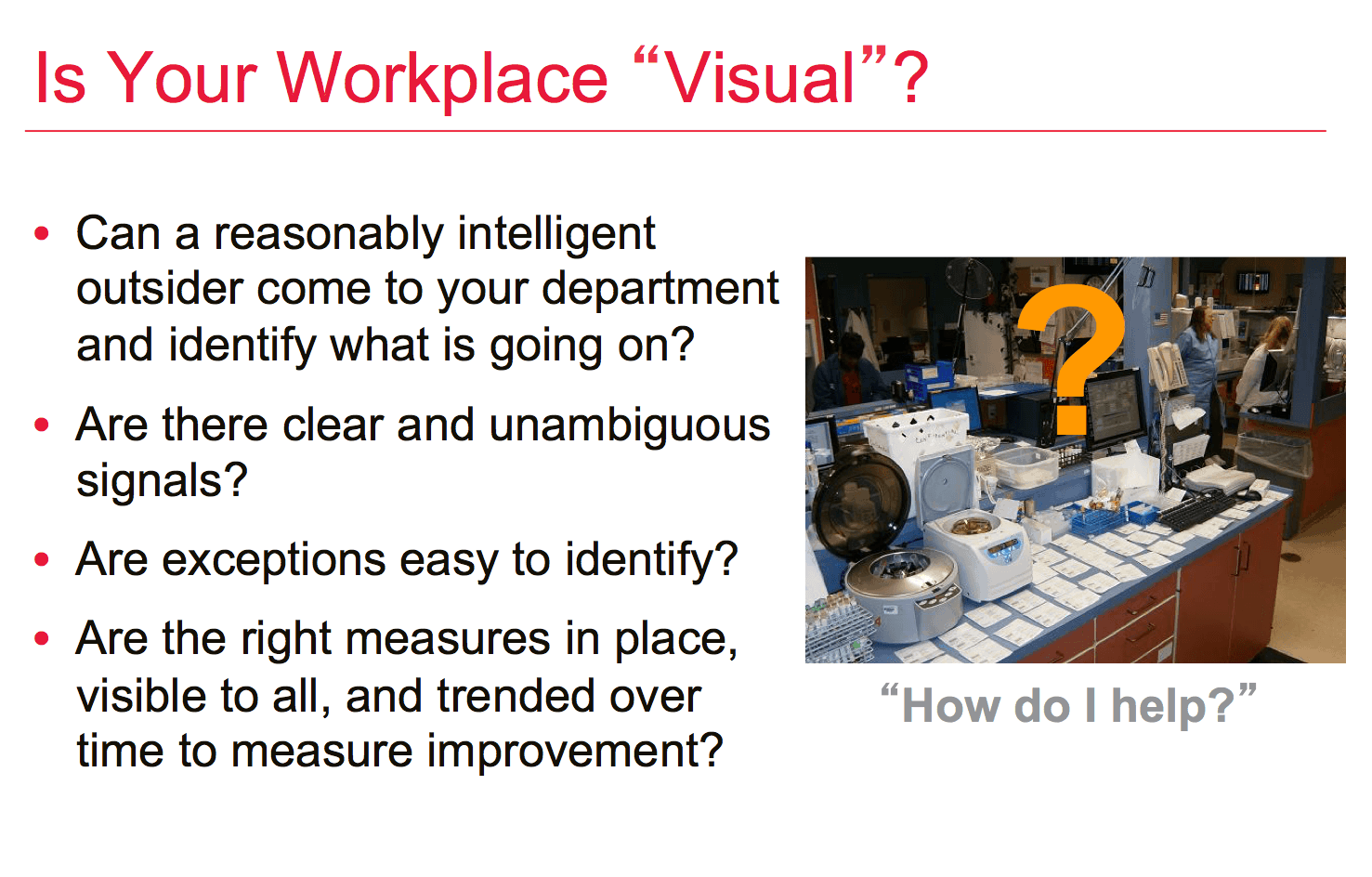

When I worked for ValuMetrix Services, as part of Johnson and Johnson, I think we did a good job of explaining visual management in our training for clients. These are slides from 2008.

Visual management has to go beyond a few charts and metrics and a few warning signs. Let's stop celebrating visuals that aren't really solving problems or improving performance.

Instead, follow the guidance of Fujio Cho… how can you make abnormal visible and what are you going to do to manage or correct that situation, in the short-term and the long-term?

What do you think? Do you see a misplaced focus on “visuals” instead of good “visual management?”

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s build a culture of continuous improvement and psychological safety—together. If you're a leader aiming for lasting change (not just more projects), I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s talk.

Join me for a Lean Healthcare Accelerator Trip to Japan! Learn More

Well stated! I especially like the thoughts around noticing an abnormal situation (if it can be detected) and then acting on it either by asking about it or behaving differently. The key is the word “management”… And management requires leadership and leadership cannot be delegated (to anything, but especially a sign). Too often people think that because lean creates visual workspaces, that creating the visual allows them to “check the box” on “being” lean. To me, it often shows the maturity of where people are in their journey… Are they checking a box and implementing a tool or are they designing something to solve a problem/meet a specific need? Thanks for sharing. You struck a chord with me today!

Mark ~ Excellent post, enjoyed the read! I recently conducted a presentation on 5s+1 which included Visual Management and I could not agree more with your statement: “If the ‘visual’ isn’t helping accomplish a goal, it’s probably not visual management…” When conducting this type training I try to stress the difference between posting performance metrics or A3 story boards (preferably in real-time), to actually achieving a Visual Management workplace (error proofing). True “visuals” improve streamlining processes (labeling), providing input/output workflow (color coding, floor taping), or safety information (posters for required PPE).

Great article and perfect timing for me to read as I’m going through OE Practitioner training this week. I appreciate the in-depth look at the topic of Visual Management

Great article, seen plenty of examples of visuals without visual management or countermeasures in place.

Mark, excellent summary of visual management. We often talk about “Daily Visual Management” systems and ask people to identify the most important word of the three in the phrase. It’s management. We coach to first identify what you are trying to manage, then make it visual and review on a frequent, periodic basis. As a Shingo assessor, I’ve seen areas where there are lots of visuals, but little management of them. When we provide feedback to the organization, we point out that what we observed was “VISUAL management”, rather than Visual Management. Thanks for the post!

Thanks for the comment, Tim. It’s good confirmation that I’m not being crabby or picky about the VISUAL management instead of full blown Visual Management.

Now, I could get on a different rant about “Lean Six Sigma” really being more “lean SIGMA” instead of being balanced or having enough Lean in it for my tastes :-)

[…] I found a great post by Mark Graban entitled Moving from “Visuals” to “Visual Management” and to Broader Lean Thinking. […]

[…] As I’ve blogged about before, “visual indicators” are different than “visual management.” Visual indicators eliminate information deficits. Visual management allows us to, “See the difference between normal and abnormal… right now!” as Toyota people say. Not all signs are “visual management.” They might be just “visuals.” […]

Great article. It was cool to see all the examples of having visuals in the workplace. The hospital example showed the visuals very well which is important for such a high-pressure environment. The visuals are very simple but can go a long way for lean.

Comments are closed.