It's far too common to see somebody with just a little bit of understanding about Lean do things that really shouldn't be described as Lean at all… in terms of the decisions they are making or the approaches they are taking.

I saw an article about Lean in physician practices: “Lean Practice Management for Physicians.” I cringed a bit when the author said:

“In lean management programs, there are levels of belts based upon the colors found in karate: white, yellow, green, black, and levels of black.”

No. That's an example of “Lean As Mistakenly Explained,” or L.A.M.E.

Hearing “levels of black” makes me chuckle and think of my all-time favorite movie “This is Spinal Tap” and discussion about a new album cover that was solid black. “How much more black could it be? The answer is none. None more black.”

As I commented on the site, “belts' are a Six Sigma practice or a Lean Sigma thing. Yeah, I think it's meaningful to point that difference out. Somebody from a Toyota factory isn't earning Lean “belts” that would signify any level of education or experience.

There was a reader comment on the article that said, in part:

“Patients are more unhappy than ever, we have gigantic 6×9′ boards with pockets that have statistics, graphs, etc which neither the staff nor certainly the patients can see what that is all about. It looks again like the company is interested in numbers, not patients.”

Who knows if the data supports the patients being more unhappy in that situation. It's possible if the term Lean is misused or abused. It's a common problem to have big huge boards that the staff don't understand, connect with, or use. I see many “huddle boards” that are forced on departments, but don't get used.

Listen to Mark read this post (subscribe to the podcast):

Some organizations misunderstand Lean and think it's about posting a ton of charts and graphs.

We CAN have charts and graphs in an environment that is patient focused. These charts can be connected logically and emotionally to staff, their work, and their mission. But it's often a clumsy, top-down initiative as I think that commenter is saying.

Senior leaders sometimes do a site visit to a fine organization like ThedaCare and they draw the wrong conclusions about what they saw and what they need to do. As Dr. Deming used to say:

“I think that people here expect miracles. American management thinks that they can just copy from Japan–but they don't know what to copy!”

How many executives come back from a site visit not realizing THEY need to change the way they manage and that they are responsible for changing the culture, not just forcing new tools on people?

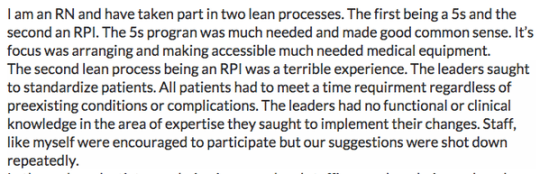

Here is another complaint about Lean that you might see online (I shared this on Twitter last week):

Spelling mistakes aside, there are some very valid concerns brought up in this story, in the “second lean process” or a Rapid Process Improvement event, as it was apparently called.

As Pete Abilla said, in response:

I don't know what consultancy it was. There might not have been a consultant involved.

We can standardize processes, but that doesn't mean that every single patient is treated exactly the same. As I saw at a hospital eye clinic in Toronto recently, the team (including physicians) helped standardize what supplies are kept in each exam room. They had input into that process, the standardization saves them time each day (since they have what they need where they need it), and standardization didn't mean every room was exactly the same. They're far more consistent compared to before.

As the nurse complained in the image above, trying to fit every patient into a time limit isn't Lean. I've written about this before. Planning a day based on typical exam or treatment times doesn't mean you have a shot clock that buzzes and says the patient has to leave because time is up.

If Lean project leaders are forcing changes on people and aren't seeking input (or are shooting down all ideas), that really shouldn't be described as Lean at all. It's more likely an example of L.A.M.E. or Lean As Misguidedly Executed.

What follows is an email discussion that I had with an organizational design consultant who has a client that is “implementing Lean” (as I've suggested maybe “Practicing Lean” is a better phrase… because they don't seem to be very good at Lean yet). The conversation is shared with the consultant's permission and I don't know who the client is.

She wrote:

“I love reading your perspective on your blog, even though you are in the health industry and I am in manufacturing.

I would really appreciate your perspective….. Is lean supposed to eliminate human error or is it supposed to inspire more mindfulness at work, or both?”

I thought that was an interesting question, so I replied:

Thanks for your email. I'd say that Lean works to reduce human error, but recognizes that we're human and that mistakes are pretty inevitable. That's why we need systems and error proofing to help prevent errors or make things robust against errors.

I'm not really sure what's meant by “mindfulness” in this context. How would you explain that? If it means “be more aware and be more careful,” that's not what Lean is going for. We're human, so we get fatigued, distracted, forgetful. You can't change that human trait… but maybe you can improve the system to reduce the number of distractions that occur, etc.

She replied:

I work with a manufacturing company right now and I have the feeling they are trying to create human robots. I guess with mindfulness I meant that people are willing, able and ready to look for a better way of doing things. I don't think lean is meant to be so error proof that people won't use their brain and own judgment anymore. Correct? There must be room for creativity and innovation.

Creating “human robots” is not Lean at all. Look at Toyota as a key example of an organization that practices “respect for people” or “respect for humanity.” That includes recognizing our human limitations (such as forgetfulness) and engaging everybody in continuous improvement. Standardized work is not meant to replace judgment or creativity.

So I wrote:

Right, the goal is NOT to turn people into robots. Far from it.

Employees help define their own standardized work. That's one radical idea that comes straight from Toyota. They aren't just told what to do.

They are involved in continuous improvement, being creative, speaking up… they can follow a standard process yet STILL have lots of room for creativity and innovation

She replied:

Thanks so much for taking the time to respond, Mark. I really appreciate it, and your response makes so much sense.

I am not a Lean expert but a lot of this stuff is common sense for me. However, common sense doesn't seem to be common these days. ;-)

I wrote back:

I wonder where this manufacturing company's apparent misunderstanding of Lean comes from? An outside consultant? One of their own leaders?

The problem with Lean is that you can't cancel out decades of bad habits… if a company treats employees like dummies or just a cost, they aren't going to see (or believe in) Lean as a way to engage people. They'll just use Lean tools to accomplish their existing goals through their existing mindsets… which is a shame. But it's not unusual.

People will then say “Lean failed,” but that's not quite right.

Her last reply:

No, they drive these changes down from the corporate office, and they totally try to rush through this change. Their quality is at its worst at the moment – not surprising as they totally start to burn people out, and the operators who are supposed to follow standardized work have no information about what' s going on. Their only involvement is that the team leaders are taking videos of them. Totally crazy rollout.

The other challenge I observe is that they are simply not good in communicating the lean journey.

I agree with you….. It's a shame!

Rushing through change doesn't work (that's one key point of the change management workshop I'm now teaching). Burning people out, forcing standardized work on people, taking video of people without engaging them. Yes, that's crazy. It's not just poor communication, it's L.A.M.E.

I'm not sure what we can do about it, but it sure is annoying, whether it's happening in a factory or a hospital.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s build a culture of continuous improvement and psychological safety—together. If you're a leader aiming for lasting change (not just more projects), I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s talk.

The fact that the same criticisms of Lean by workers exist today as they did since the dawn of progressive management 100 years ago suggests we focused on the wrong thing – rapid implementation of Lean tools. More specifically, the Lean movement successfully influenced leaders but failed to respect the people (workers) that have these important and real concerns. Workers concerns must be addressed by management from the start.

Agreed

“How many executives come back from a site visit not realizing THEY need to change the way they manage and that they are responsible for changng the culture, not just forcing new tools on people?”

I believe the best way to change culture is lean storytelling.

OK, tell me more… executives should come back from site visits with stories? What sorts of stories?

I’d still be concerned if all of the stories are about how front line staff or managers need to change…

Mostly collect stories from your employees. Lean started back in the 1980s. It is likely some of your employees are already practicing lean. Build on these successes. One success usually leads to several more. These successes may be hidden due to poor management. If these stories are ignored, it is likely employees proficient at lean will leave the company.

Some stories that deal with managerial change should come from other companies. Instead of chastising a manager for his behavior, use a story from another company about a manager acting poorly to start a discussion about proper lean manager conduct. If that does not work, individual behavior should be addressed.

Yes, executives should come back with stories. The lessons in these stories are typically applicable to other occupations/industries.

Mark;

As much focus that continues to come out about coaching and respecting our team members, these stories continue to surface. One of the key elements I share with others embarking on the lean journey is that the process works much better when executed “with team members” instead of “to team members.” From what I’ve seen there remain far too many organizations that support the cultural transformation from the very top CEO level and have that CEO engaged. We’re fortunate as an organization to have that support and engagement. Another obvious factor is the lack of having a real “why” behind the lean transformation. If it’s simply for cost reduction then the ability to sustain will never be reached in my opinion. Sadly your story shows we have a long way to go on the behavioral, cultural and people side of lean. In the end we must understand we partner to support and coach “human beings” and not “human doings.”

You’ve rightly pointed out many times, including in this post: lean is not the set of tools many organizations deploy. That is L.A.M.E. You can’t install lean or implement it; you practice it. I believe you cannot practice it without understanding systems, sources of variation, human psychology (individual & group), and the way we learn, and how these four domains interact with each other i.e. Deming’s System of Profound Knowledge

I posted on the Deming Institute blog today about the problems when people try to copy

http://blog.deming.org/2015/09/people-copy-examples-and-wonder-why-they-dont-succeed/

which normally means copying without learning first (with our common focus on quick and easy action). The same issue drives LAME – it is taking something you overhear one person say (who often doesn’t know what they are talking about) and then you say lean means…

But if spend any time researching you can quickly learn that a LAME claim is not close to accurate. The main difficulty you will have is how you use your critical judgement to evaluate conflicting information (because you can find some really LAME ideas in quick Google searches). That is the type of thing that I was taught to do in grade school, high school and college. Sadly this skill also is often lacking and without the ability to sort through conflicting information in a sensible and quick manner we are sadly likely to continue to see many LAME implementations that should have been avoided with even cursory critical thinking.

Now even if you avoid the pretty easy to avoid LAME actions doing lean well can present challenges. But at least you will spend your energy on sensible and appropriate challenges and not things that you should be subjected to by consultants or managers that have even a cursory understanding of their field.

[…] But, as Dr. Deming used to say (and I cited recently): […]

This is an excellent blog. I remember a blog where you posted the 5 biggest mistakes organizations make when implementing LEAN. Could you post it again please?

Not sure that was my post, Lorraine.

I did have a post on 10 common Lean problem solving mistakes.

and a post about Lean not being an acronym :-)