The phrase “Lean journey” is used widely to describe an organization's transformation over time. It's either a phrase that invokes helpful imagery or it's a horrible cliché. I was speaking at a Lean event last week and I kept hearing “Lean journey” come out of the mouths of most speakers.

It probably counts as a “Throwback Thursday” post to then think back to the band Journey — a group that hit its peak in the late 1970s and early 1980s. Journey was most popular when what was then known as “just in time” or “Japanese management practices” were being discovered in the West — what's now called “Lean.”

So, it's more than appropriate to use this phrase “Lean Journey.” The band, formed in San Francisco in 1973, was by no means an overnight success. Like many factories (and hospitals), they were forced to bring on new leadership and a new front man… in the case of Journey, Steve Perry, the lead singer during these peak years.

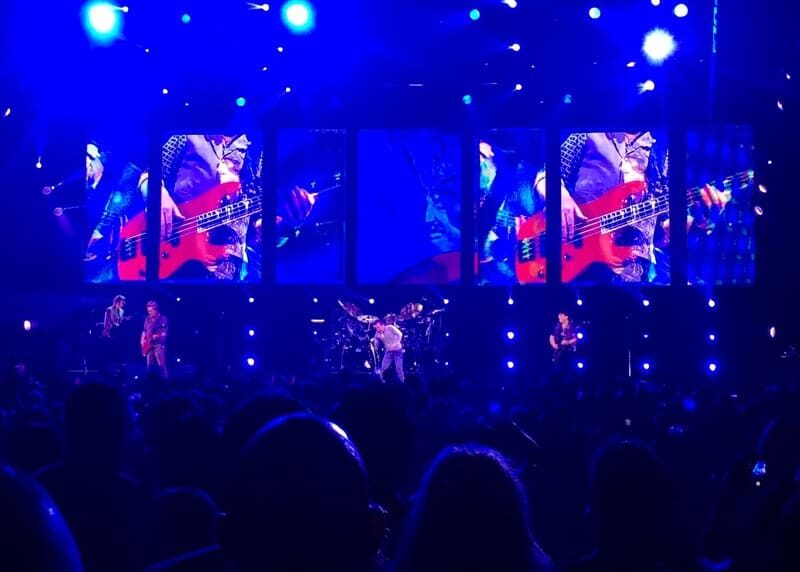

A few weekends ago, my wife and I spent the weekend in Las Vegas and the friends who were with us insisted on seeing the band Journey perform live at the Hard Rock Casino. Even though they now have a new lead singer, Arnel Pineda, it was a great show and the audience had a lot of fun. Here's a picture from the show:

The songs have been stuck in my head ever since. When I spoke at the Lean event and was hearing “Lean Journey” over and over, I could help but starting my talk with the following question about a Lean Journey inspired by the band Journey and one of their greatest hits…

Are people embracing your Lean journey with “Open Arms?”

Done right, your employees should be embracing Lean and participating enthusiastically. They'll do so if Lean is focused on creating a better, less frustrating workplace, and if they're being engaged in improvement. If Lean is about, ahem, putting tape around everything on their desk, then people won't embrace Lean.

So after making a few bad puns about Journey songs, I challenged myself to utilize as many song titles from their “Greatest Hits” album into a blog post. What problem am I solving? I don't know… but let's have some fun and learn something.

Back to “Open Arms” — If your employees are “resisting Lean,” leaders shouldn't blame the employees.

Leaders should ask if they are executing these strategies and utilizing proven Lean leadership concepts “Faithfully?” Are we holding true to proven Lean principles and the Toyota approach to management? Or are we just using new tools and our old mindsets?

Lean is not “mean.” Lean should be focused, as John Shook says, on solving problems that matter.

Thinking about customers (or patients) and our staff, ask “Who's Crying Now?” These people aren't complainers… they are identifying things that need to be fixed or processes that need to be improved?

The band learned, apparently, all of these Lean concepts while touring in Japan. They are, it seems, the unsung heroes in spreading Lean throughout the world.

You might know the story about how the famous song “Lights” had the lyrics changed to be more about San Francisco (“the lights shine on the Bay”). The popular story is that the song was originally about Los Angeles, but it was really originally about the NUMMI plant in Fremont, California (a Toyota/GM joint venture that I've blogged about). Neither Lean nor Fremont are really inspiring song topics.

The original lyrics for “Lights” were about the tale of a Toyota-style “team leader” coming to help front-line production associates were you were used to an old style of GM leadership…

When the lights go on in the factory

The andon points the way

I want to be there… solvin' problems

Ooh, ooh

So you think you're lonely

Well I'm here to help you now

I want to get the line back runnin'

Ooh, ooh

As we've learned, at NUMMI, other factories, and now in hospitals, you can have the process work “Any Way You Want It.”

We need to have “standardized work,” developed by the people who do the work that helps us produce consistent quality and to do so safely. We don't want to go overboard with standardization and standardize things that don't matter. We do

Cn't want to eliminate judgment completely, but you can't do the job the “way that works for you” or “any way you want it.”

Customers, however, should be able to get their care or product or service “any way THEY want it” as Lean allows us the flexibility to be more customer focused in meeting people's needs.

Before NUMMI created a Lean culture, it was a really sad situation where management and the workers were basically going “Separate Ways.” And, quality was going down while cost was going up (does that sound familiar, healthcare?). Those metrics only go separate ways in a traditional culture. In a Lean culture, quality and cost are both improving — going the same way.

The song also referred to how Toyota, Honda, and Nissan had management practices that were very separate from those of the Big Three… and the results of those companies were going separate ways, as well. Something had to change.

Unfortunately, too many factories (and hospitals) have rejected Lean thinking. They haven't been willing to try a new way (or maybe they haven't felt the need to). They've said “I'll Be Alright Without You.” Are they really?

In a Lean culture, we embrace new employees and invite them to point out problems. As Journey teaches us, “Only the Young” have fresh eyes to see waste that everybody else has become blinded to.

https://www.youtube.com/watch?v=qhrOaO8YCY4

That video has the “fresh eyes” singer, Arnel Pineda, who joined the bad about eight years ago.

When we get everybody involved in Kaizen and continuous improvement, the Japanese describe that as “spinning the PDCA cycle” (as I heard at many organizations in my last Japan tour – join us in September, by the way).

Did you know the Journey song “Wheel in the Sky” is really about that PDSA wheel and how it “keeps on turning?”

The lyric in the next song might be a bit sexist (it was the 1980s), but once you get people participating in Kaizen — when they are being listened to and rewarded for pointing out problems and fixing things, “Girl Can't Help It” but to keep improving. The same applies for men.

That sounds just like the “Kaizen queens” at Franciscan St. Francis Health – they can't help but keep improving.

When we consistently (ahem, faithfully) pursue these strategies… and when leaders start leading in a new way, “Don't Stop Believin'” that you can create a sustainable Lean culture — even in a factory in “South Detroit” (ahem, Windsor).

What problem are we solving? Better safety, better quality, better customer service, lower cost, better workplaces… that's what makes the Lean Journey worth all the effort.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

If you’re working to build a culture where people feel safe to speak up, solve problems, and improve every day, I’d be glad to help. Let’s talk about how to strengthen Psychological Safety and Continuous Improvement in your organization.

Nice analogy, Mark, but now I’ll have Journey songs running through my head all day. Thanks for that. :)

I was trying to share that joy, the joy of those songs being stuck in my head, with others! :-)