tl;dr: The blog examines the pitfalls of poorly executed Lean methodologies, using an analogy of a cheeseburger to discuss unhealthy implementations. It argues for a nuanced approach to Lean, acknowledging its limitations and ‘horror stories' in order to effectively achieve sustainable improvement.

When people ask me why I do what I do, my first answers are:

- improving patient safety

- creating better workplaces for people

It's as simple as that. Those are the important problems that I'm passionate about (and have been able to help fix, at least in some local situations). At a more global scale, to o many patients are hurt or killed by preventable medical errors. Too many people end up hating their jobs or going home crying or exhausted at the end of the day. That needs to change.

In my 20-year career, in manufacturing and in healthcare, Lean has been a powerful and effective methodology for meeting those goals, along with improving quality, reducing waiting times (for products or for care), and reducing cost.

But, not always.

Lean tools can seem pretty simple to apply. But, we see something as basic as 5S get misapplied all the time (see this blog post and this satirical video I created). There's a reason that the “Bad Office 5S Video” has over 135,000 views. It's not just because it's funny… it's because there is a kernel of truth that resonates with people.

Lean is about creating a better workplace, one where employees are listened to and supported, where employees are allowed to participate in continuous improvement.

If people are irritated, annoyed, or outright ticked off because of Lean, there's probably a big problem.

And, that problem is NOT employees who are “resistant to change.”

A tool as simple as 5S is supposed to engage employees in making their work easier, improving quality, preventing problems and frustrations, and allowing them to do a better job for customers and patients.

But, in the hands of a clumsy, old-school manager, 5S becomes a new, overbearing weapon. Forcing people to remove family photos or making them put tape around their keyboard… that's not Lean. That's annoying.

Yet, the use of tools without the context of Lean philosophies or a Lean management system still gets labeled as “Lean.”

I call this “Lean As Misguidedly Executed,” or L.A.M.E. (an awkward acronym, I realize).

When managers do bad things to employees in the name of Lean, this is called a “Lean horror story,” not a “bad manager horror story” or a “workplace horror story.”

Listen to Mark read this post (learn more & subscribe):

People can do any ole' dumb thing and call it “Lean.”

An Analogy to Nutrition and Lean Living

As an analogy, let's say a person reads a book about nutrition. Maybe they don't really want to lose weight or have a newer, healthier lifestyle. Maybe they were told, by a doctor or a loved one, to read that book.

Let's say that person does a quick web search instead of reading the book. They might find all sorts of crackpot ideas and snake oil nutrition information that's more self serving than accurate.

Or, maybe they read the book, but they cherry pick the parts of the book that fit with their existing diet.

They might read that protein is good for you. Eating the right kinds of protein can help build muscle and shed pounds. But, you also have to exercise more (and exercise the right way, perhaps with a coach, as I have done and written about).

So, this hypothetical person I'm writing about decides, “I'm going to eat cheeseburgers for lunch and dinner every day because they are high in protein and calcium. And I'll throw bacon on there for more protein.”

Well, you don't get to label that a “healthy diet.” Or, if you did, you'd be wrong.

I've had people express interest in our Healthcare Kaizen books and they'll say something like:

“We've been implementing Lean for five years and now we're going to focus on trying to engage everybody in continuous improvement.”

Hmmmm…. is that really Lean then if you're not engaging everybody in improvement, or are at least trying to? Lean, based in part on the Toyota Way management system has two core pillars (“equally important pillars,” as Toyota has called them): continuous improvement and “respect for people.“

Some of those clumsy or misguided 5S initiatives are pretty lacking in respect for people. A Lean program or initiative without real continuous improvement isn't really Lean… Rapid Improvement Events (aka Kaizen Events) are fine, but those are sporadic and episodic improvement, not continuous improvement.

Horror Stories Are Out There

As a “Lean Community,” we can't ignore the “Lean horror stories.” We should try to speak up and educate people about what Lean is really about. Or, we can try to figure out how to have fewer people get an incomplete or incorrect understanding of Lean.

I saw this article, which is from a labor union publication (so insert your own positive or negative bias here), but let's assume the story is true.

Amanda says her floor supervisor, a former Toyota group leader, publicly humiliated her until she finally broke down. “One day while he was yelling at me, I told him that I am going to kill myself if you keep talking to me like this. He sent me to the medical bay. The medical bay put me on short-term disability.

“I saw a therapist who said I was fine as long as I was moved to another line. The Volkswagen doctor refused to clear me.” Amanda never returned to work at VW, believing it easier to find another job than to fight the company.

Company documents show VW's management method is modeled on “lean production,” the philosophy created at Toyota, then popularized across the auto industry and beyond.

“Every employee there busts their ass and is injured and is working through the pain because they don't want their job taken by a temp,” Amanda says. “It is made clear to all of us that we are easy to replace.”

None of that sounds very Lean to me. If that's what Lean was, hell, I'd become a union organizer and fight against things like that.

I hear complaints about Lean from healthcare professionals. I read about them in the news. I cringe at much of what I hear. It doesn't sound like the Lean I've practiced or written about. It doesn't sound like a recipe for better safety and better workplaces.

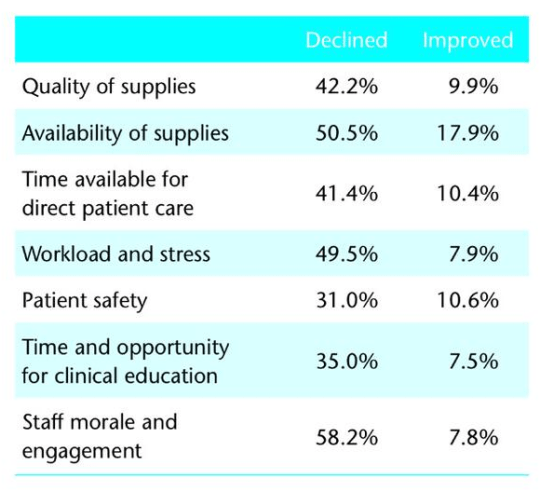

There was a survey taken and published by a nurses' union in Canada, about their perceived impact of Lean. It doesn't paint a great picture:

The left column is the “declined” tally and right number is “improved” (it's a bit hard to read the text).

If staff morale and engagement is getting worse and patient safety is at least perceived as getting worse… that's a big problem. Lean is supposed to IMPROVE all of those dimensions. Something ain't right.

It's really frustrating to hear about the instances of “L.A.M.E.” that occur. If we only highlight the good things that are going on (like better quality and safety in some hospitals), and not the problems of “Lean horror stories,” then I think we do a disservice to all.

Far too many have been afraid to speak up when they hear of such horror stories. I've heard luminaries in the Lean world basically shrug their shoulders and say, essentially, “Well, people are going to do bad things and you can't do anything about that.” I say that's hogwash. We have to speak up and try to educate people, otherwise Lean gets a bad name and we lose our chance to great better workplaces and safer patient care.

Bob Emiliani is one who has been brave to speak out (see a recent blog post of his).

There's a book that was written as a cautionary tale, a story of “bad Lean”: Look Before You Lean: How a Lean Transformation Goes Bad–A Cautionary Tale.

But, these things still happen.

I'm sincerely interested in hearing your “Lean horror stories,” if you'd share them. I can promise empathy and confidentiality, if nothing else. Please contact me.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

You can also read this post in Spanish (which was translated with my permission):

http://www.leanauren.com/2015/03/no-podemos-ignorar-las-historias-de.html

Thanks Mark for sharing your post with our Spanish readers. Very interesting information

I’m just mad that I cannot eat a burger for lunch each day. Actually great article & it never ceases to amaze me what I have seen labeled as Lean. I had never seen that video but have came across people very much like that.

The nurse’s poll is very disappointing