I do my best to “practice what I preach” in terms of Lean and Kaizen principles and spirit. No, I don't have tape outlines around the items on my home office desk (which would be, at best, a superficial copying of 5S practices).

I do my best to “practice what I preach” in terms of Lean and Kaizen principles and spirit. No, I don't have tape outlines around the items on my home office desk (which would be, at best, a superficial copying of 5S practices).

But, for example, I try hard not to blame. I use checklists for podcasts and webinars to help prevent errors. Joe Swartz and I listened to the “voice of the customer” and created The Executive Guide to Healthcare Kaizen after readers told us that the full Healthcare Kaizen book was too heavy and too detailed for senior leaders to carry on a flight to read. We've also tried to provide some transparency about our workshop quality outcomes.

I've also tried to embrace continuous improvement in all aspects of the practice of Kaizen.

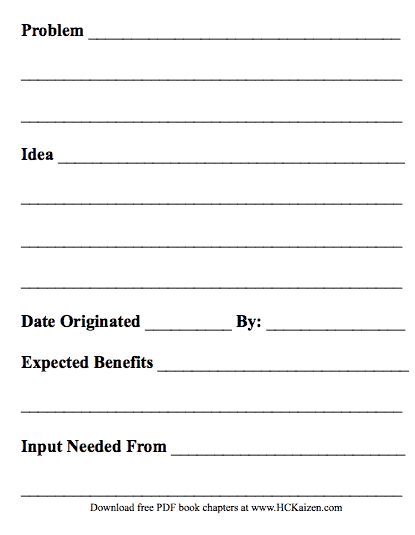

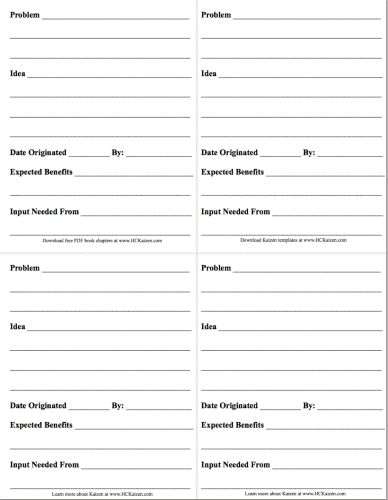

For example, in the book (and on our website), we present a pretty basic “Kaizen Card” template for consideration. This is the front side of the card:

There are certain key elements that should be pretty consistent, such as asking for a problem, not just an idea. But, we provide editable templates, because we want people to be able to customize the cards for their own use.

These customizations that I've seen include:

- Using the word “opportunity” instead of “problem”

- Listing “name” instead of “by”

- Adding an organizational logo

- Adding checkboxes for categories instead of free-form “expected benefits”

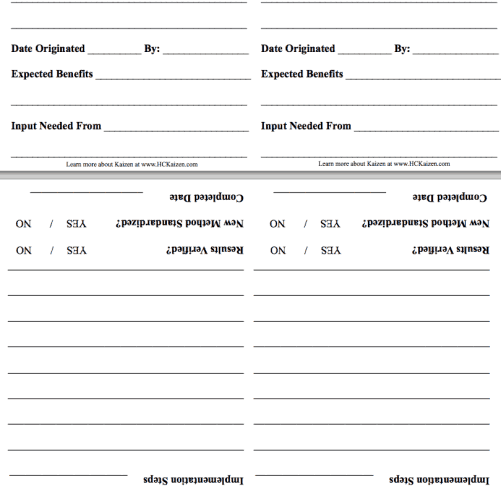

I had one client suggest printing the backside of the card upside down so that, when it's pinned to a board, you could read the back side of it by just flipping it up on the board.

That was helpful for them, so we now provide a version of the template with the backside of the card flipped upside down.

More recently, I had a client email me with what he would have written on a Kaizen card:

Problem: Difficult to determine where to cut Kaizen cards

Idea: Dotted cutting lines

Benefits: Less time cutting, better cutting quality

This situation shows what happens when we make assumptions…. we have trouble seeing problems as our customers see them. My assumption all along was that the Kaizen cards would get printed by a hospital's print shop (or I get them printed at FedEx Office).

I can print the cards at home, but the benefit to using a print shop is that they have the equipment to automate the cutting of the sheet into equal fourths. I never do this with scissors.

My client was printing small batches of cards and was cutting them with scissors. His suggestion about the dashed line would help make that easier for him.

Without trying to be overly negative (it's not very Kaizen-y to just shoot down an idea), I did ask him if the hospital had print shop capabilities or if he could pursue that as a longer-term countermeasure.

That said, it was easy enough for me to add a version with dashed lines. I did think through that the dashed lines only needed to be on one side of the card, not both :-)

Now that we've done the Plan and Do phases of PDSA, the next step was for my client to test the new template and then Study how it works, to see if we needed to Adjust. He printed the cards and studied how they worked.

He wrote:

I tried it out, and here's what I found (Do-S-A! Do-S-A!) Thank you for implementing this Kaizen–I found it to be much easier to cut and it makes it a bit easier to get my cutting lines straight. I took out the old trusty ruler and measured the lines and distances from the edges, and to get the thing centered vertically, here are my recommendations:

If you shift the margins a little on the left (about 1/16th), to make it 1/8, that should shift the center line to the right spot and make it even on both sides. The yellow is meant to show where a line is either shorter or longer than the first line (though my eyes might have deceived me on a couple).

This was very helpful and specific feedback. I tweaked the cards to make sure the dashed lines were perfectly centered horizontally and vertically. I printed the cards and tested them myself rather than asking my client to do it (I probably should have done that the first time).

Kaizen — making a small change for the better for my client. And, by sharing the template more broadly, we're potentially sharing the idea to help others, which is an important step in the Kaizen process:

- Find problems or opportunities

- Discuss them

- Implement (test) them

- Document them

- Share them

———-

Do you want to see what a “culture of continuous improvement” looks, sounds, and feels like? Check out this workshop (more of a mini conference) that Joe Swartz and I are holding in April at his health system in Indianapolis. Please come join us.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

Mark,

I think it’s great that you practice what you preach. It’s not always an easy thing to do, but it’s essential that we model the behaviors we want others to adopt. If we want associates to be engaged, we have to listen and respect their suggestions (especially when they could use some coaching to develop their ideas further). When an associate willfully offers an improvement opportunity or identifies a problem, they’re offering a piece of their spirit – and should be treated like gold.

Completely agree, George! If we always have all the answers, then how do we help others develop their problem solving skills? And is it even possible to always have all the answers? I’ve been pleasantly surprised many times just by taking the time to listen to an idea with an open mind.

Ok! Now back side flipped with lines!

Just a side story regarding the tape thing and assumptions… way back about 4 or 5 years ago a couple of our offices had a 5S “improvement” which involved an obsessive amount of tape and labels (red outline around the trash can which was labeled “trash can”). Most of the unnecessary stuff has since been removed, but we recently had a patient comment about how nice it was that the ugly tape around the garbage cans was cleaned up. The patient didn’t value the tape (and neither did the physicians or staff), therefore it was waste around the waste receptacle. Just goes to show that feedback from the customer is critical. Otherwise it’s just Lean for Lean’s sake.

Ha ha… now if somebody suggests “make yellow cards so I can print them as yellow” I would probably have to push back and suggest that they just print them on yellow paper :-)

Yeah, there are many instances where people go overboard with a tool. “We have to put tape around everything!” Why? “Because Lean says so.”

Nope.

Instead of “Lean for Lean’s sake” maybe a situation like you described isn’t Lean at all, really?

That sounded harsh. But maybe know what I mean.

As I said in this podcast, it’s such an important Lean principle to “start from need” as Taiichi Ohno said. What problems are we trying to solve?

Is the trash can ever missing? Does it ever create a tripping hazard because it’s in the wrong place?

From LinkedIn:

Brett Gopal said:

Thanks, Brett Gopal – I agree with your assessment that most of the problems are in the C and A phases… either done badly or not done at all. There’s a lot of Plan-Do – or just Do – happening out there.

One of the problems I always encounter with Kaizen is that individuals and organizations over-complicate things. It’s not about a giant breakthrough idea, but rather the collective impact of many small and simple ones.

This is a great example of how simple Kaizen works. More folks should do it this way.

I like the idea cards published here quite a bit. When printed, they end up becoming 4 cards on a sheet of legal paper that are just a touch under 4×6. Any ideas for how to store them near/on magnetic white boards or cork boards? Ideally, a 4×6 magnetic index card holder would be ideal. I haven’t found such a product. So, we have clips holding a handful of empty cards to the boards. This works ok, but when an employee grabs a card, the other cards frequently fall on the floor.

I’ll ask the folks at StoreSMART if they have any ideas.