Tomorrow afternoon, I'm doing two different webinars that I hope you'll want to sign up for.

Even if you can't attend live, I'd encourage you to register in advance so you can get links sent to you automatically to view these on demand. Both webinars will be recorded and links will be sent out to those who registered.

KaiNexus – Leadership Behaviors for Kaizen

First is a new webinar that Dr. Greg Jacobson and I are doing through KaiNexus. It's titled “More Leadership Behaviors That Create a Culture of Continuous Improvement.” We did a webinar last year on “25 behaviors” for creating a Kaizen culture. That just scratched the surface, so we're going to talk about another 15 or 20, with examples and stories, based on our recent experiences with different organizations. You can also read about the first 25 behaviors in this free e-Book or my blog post.

First is a new webinar that Dr. Greg Jacobson and I are doing through KaiNexus. It's titled “More Leadership Behaviors That Create a Culture of Continuous Improvement.” We did a webinar last year on “25 behaviors” for creating a Kaizen culture. That just scratched the surface, so we're going to talk about another 15 or 20, with examples and stories, based on our recent experiences with different organizations. You can also read about the first 25 behaviors in this free e-Book or my blog post.

Kaizen isn't as easy as just hanging up some bulletin boards or buying software. Kaizen requires leadership – a certain kind of leadership and behaviors that encourage, support, and reinforce people's willing participation in improvement.

Some of these behaviors we'll discuss on Tuesday include:

- Don't be inadvertently threatening when asking for ideas

- Don't say “that's not really a problem”

- Emphasize and try small tests of change

- Prioritize learning over financial benefits

Have you seen or practiced any of those in your organization? What other behaviors would you suggest are important for leaders at all levels (or at a specific level, like senior leadership)? Leave a comment on this post to let us know.

Kronos & Becker's Hospital Review: Lean and Your Workforce

Thanks to Kronos, the sponsor, and Becker's Hospital Review, the host, I'm leading another webinar later on Tuesday titled “Lean: Transforming Healthcare Delivery by Uncovering Opportunities Within Your Workforce.”

There are many articles that use the phrase “the people side of Lean.” That always makes me do a double take, as I think “what else would Lean be?” if not about people.

I'd argue that if you're not engaging everybody, or most everybody, in an improvement process, then it's not really Lean. If Lean somehow means forcing technical changes, tools, or solutions on people, that's sort of missing the point of Lean as a management system and an organizational culture.

I'd argue that if you're not engaging everybody, or most everybody, in an improvement process, then it's not really Lean. If Lean somehow means forcing technical changes, tools, or solutions on people, that's sort of missing the point of Lean as a management system and an organizational culture.

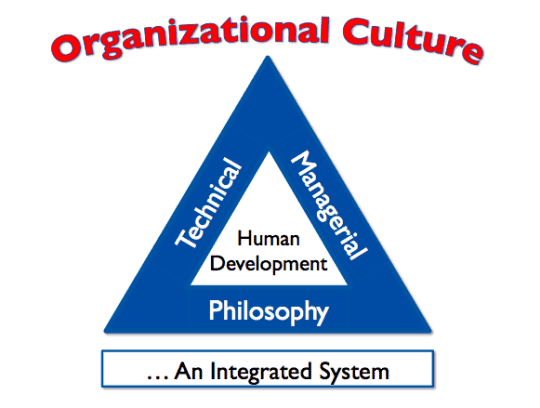

Lean is not JUST a toolbox. I often hear people say something like, “Lean and Six Sigma are just tools in the toolbox… pull out the right tool at the right time.” That sells short the power of Lean.

There are important tools to be used… but we also have to understand the thinking and principles behind the tools and the problems we are trying to solve. We could use 5S as a tool, but do so in a clumsy way that alienates people.

Or if we include Lean principles such as reducing waste, respecting our employees, and focusing first on safety and quality for patients, then we'd probably use that same 5S tool in a way that really helps everybody involved. Utilizing 5S to save time for nurses and techs frees up time for patient care, which leads to fewer falls, for example, and better satisfaction scores for staff and patients. For example, ThedaCare freed up hours each day using 5S and kanban:

Lean isn't just a toolbox. And it's not “just about people.”

Toyota teaches us that Lean and TPS are a balance of technical methods, philosophy, and management practices (as Jamie Bonini talks about so well).

I've used this diagram based on what I've learned from Toyota over time:

In that webinar, I'm going to try to explain how engaging people, the entire workforce, is a major part of Lean. How do we engage people in Kaizen and continuous improvement? How do we avoid focusing on trivial things like banning sweaters from the backs of office chairs?

I hear people often say, “We've been doing Lean for years, now we're focusing on employee engagement” or they're now focusing on continuous improvement. Better late than never…

Update: Here is a recording of the webinar:

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

The recording of the KaiNexus webinar is up:

http://info.kainexus.com/webinar-recording-more-leadership-behaviors