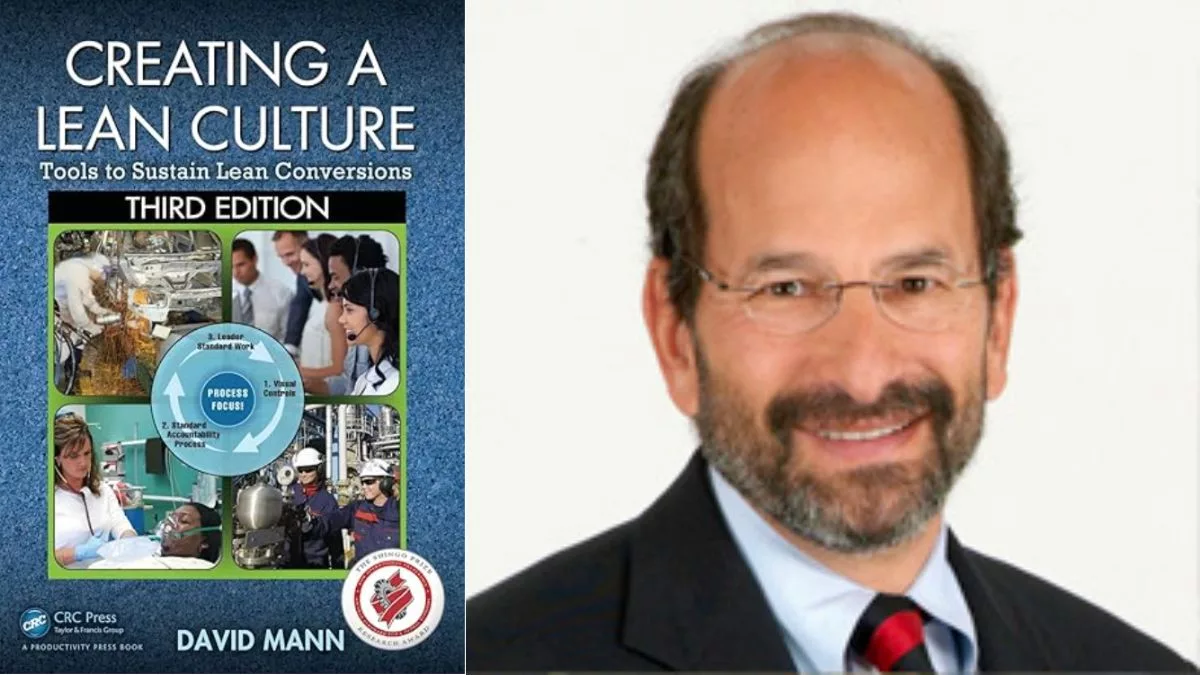

Today's guest is David Mann (bio), who is talking about the new 3rd edition of his Shingo Research Award-winning book Creating a Lean Culture. David tells us what's new in the book, and we discuss “leader standard work” and other elements of a Lean culture.

David also talks about the difference between “Lean production” and a “Lean management system,” and we discuss forcing “compliance” versus leaders teaching and learning in the workplace. What is the role of executives in creating a Lean culture? I hope you enjoy the discussion. David was also one of my earliest podcast guests, back in Episode #9.

For a link to this episode, refer people to www.leanblog.org/212.

For earlier episodes of my podcast, visit the main Podcast page, which includes information on how to subscribe via RSS or via Apple Podcasts. You can also listen via Stitcher.

Scroll down for an article based on the episode and an automated transcript.

Podcast eBook:

Feedback & Comments:

If you have feedback on the podcast, or any questions for me or my guests, you can email me at leanpodcast@gmail.com or you can call and leave a voicemail by calling the “Lean Line” at (817) 372-5682 or contact me via Skype id “mgraban”. Please give your location and your first name. Any comments (email or voicemail) might be used in follow ups to the podcast.

Article About the Episode:

Lean Management Excellence: Sustaining the Lean Journey

Lean management principles have gained widespread recognition in various industries over the past decades as a means of improving efficiency, reducing waste, and enhancing overall performance. These principles, stemming from the Toyota Production System, focus on creating value and flow along with encouraging continuous improvement. However, a critical aspect that ensures the long-term success of Lean implementations is indeed the culture within the organization and the mechanisms that establish Lean behaviors across all levels of the enterprise.

The Importance of Cultivating a Lean Culture

Creating a sustainable Lean culture is fundamental in ensuring that the beneficial changes brought about by Lean practices continue to thrive and evolve. It's not enough to merely introduce new systems and workflows. An organization must embed the ethos of Lean within its people. Business pressures such as increased competition, demanding capital markets, and sophisticated customers – often described as the “three C's” – are driving forces for companies to adapt their operational models into more Lean-focused and agile frameworks.

The Role of Leadership in Lean

Leadership plays a paramount role in the transition to and maintenance of a Lean environment. Influencing and preparing employees – especially those at the supervisory level – for the cultural shift that accompanies Lean transformations is a task that requires careful planning and execution. Transitioning from traditional production models such as batch and queue systems with accompanying outdated pay systems to Lean's more efficient processes is a significant change for any organization. Preparing supervisors to communicate effectively about these changes is crucial.

Leaders must be equipped not just with the understanding of what is changing, but also how to manage and sustain these changes. This includes helping them articulate the case for change eloquently and to respond to their teams' concerns in a way that aligns with the company's new Lean direction. Developing this leadership capability is the backbone of successful Lean transformation.

Sustaining Lean Conversions through Behavioral Changes

It's one thing to change processes; it's quite another to change behaviors. Successful Lean implementations depend heavily upon the behavior of those involved, particularly those who manage the processes on a day-to-day basis. A Lean management system that complements the Lean production system is crucial. Training and sustaining behavioral changes across teams and supervisors is vital for maintaining the continuous improvement of processes.

Continuous Improvement and the Lean Management System

The idea of continuous improvement underpins every aspect of Lean methodology. This philosophy requires not only adjusting systems and production lines but also, and perhaps more importantly, continuously developing the people who make the system work. Often, businesses struggle not with the initial implementation of Lean methods, but with sustaining the momentum once the external consultants have left and the spotlight has shifted. It is here that a robust Lean management system shows its value, providing the support and structure upon which lasting change can be built.

Educating for Lean Management

For sustainable Lean culture, education and development structures need to be in place, encompassing all stakeholders in the organization. This can include formal training, mentoring by those proficient in Lean principles, and regular engagement in Lean discussions. Adjunct faculty roles in universities, participating in regional boards for manufacturing excellence, and other educational engagements contribute to broadening the scope of Lean knowledge dissemination.

Speaking, Sharing, and Advancing Lean Principles

Speaking engagements and contributions to Lean-related publications extend the discussion on Lean management beyond internal corporate boundaries. The sharing of experiences provides invaluable insights into sustaining Lean conversions long-term. Examining the success stories and challenges in Lean journeys through forums such as podcasts, industry magazines, and boards facilitates the ongoing exchange of knowledge.

In conclusion, embedding a Lean culture within an organization is a multifaceted challenge that encompasses more than just the shift in operational procedures. It entails a fundamental change in behaviors and mindsets – a journey that demands leadership buy-in, broad-based education, and the establishment of a supportive Lean management system. Only by addressing these elements can organizations hope to sustain the benefits of their Lean transformations and continue to thrive in competitive and ever-changing markets.

Implementing Visual Tools for Lean Supervision

To overcome the challenges Lean supervisors face, the introduction of visual tools is an invaluable step. These tools, comprising hour-by-hour production tracking charts, operator status boards, and performance indicators, serve a dual purpose. On one hand, they simplify the supervisor's task of identifying the state of production processes at a glance. On the other, they empower operators by providing immediate, visual feedback about their work and its value within the overall process.

The Hour-by-Hour Tracking Approach

Hourly tracking charts have evolved as a standard practice in many Lean organizations. By narrowing the focus from a daily overview to an hour-by-hour perspective, supervisors can intervene promptly when production lags behind schedule. This proactive involvement not only prevents the accumulation of backlogs but also encourages a problem-solving mindset that tackles issues as they arise.

Ensuring Adherence to Standard Work

Emphasizing the importance of standard work for both team leaders and operators is crucial. The repetitive nature of this work ensures that essential tasks are completed effectively and efficiently. Supervisors need to understand their role, not just in enforcing these standards but in supporting their teams in adhering to them. By championing the literal and figurative ‘stop signs' team leaders have, supervisors can prevent interruptions that may compromise the process flow.

Building Hierarchies for Lean Checks and Audits

A hierarchical system of checks and audits is beneficial for ensuring that every level of the organization remains aligned with Lean principles. It is akin to quality checks in lean assembly processes, where the output of one function is the input to another, necessitating constant verification of correct execution at each stage.

From Team Leaders to Executives: A Cascade of Accountability

The Lean philosophy embeds accountability throughout the organization, from team leaders right up to plant managers and executives. Each role has a portion of their time dedicated to this oversight. For team leaders, it's ensuring production operators follow their standard work. For supervisors, it's about guaranteeing team leader adherence, and for value stream managers, it's about oversight of supervisors. Even executives are involved, often following a structured checklist during their time on the production floor.

Making Process Focus a Habit

Through continuous engagement with the Lean system and maintaining the integrity of standard work, supervisory roles begin to transform. What may once have felt like a constriction becomes a liberating force that aligns individual roles with organizational priorities. The focus on the Lean process becomes second nature.

The Shift from Reactive to Proactive Leadership

Training and experience lead supervisors to move from firefighting to predicting and preemptively addressing problems, displaying a proactive leadership style more aligned with Lean principles. This shift is significant not only for the smooth operation of production but also for creating a culture where continuous improvement is the norm rather than the exception.

Embracing Standard Work for Supervisors

The resistance supervisors may feel towards adopting standard work for themselves can be mitigated through education, training, and proof of concept. Standard work helps supervisors stay on task and gives them a more in-depth view of what is going on in their area. As supervisors begin to see the benefits of reduced chaos and increased predictability in their work, they are more likely to embrace the established standards.

Building Trust through Transparency and Support

Building trust with supervisors involves transparency about the intention behind changes and offering robust support as they transition to Lean processes. When supervisors see that improvements lead to a reduction in stress and more manageable workflows, their buy-in grows. This trust further develops as they are given the necessary tools to succeed and the autonomy to contribute positively to the Lean journey.

Continuing education and leadership development are critical factors in ingraining a Lean culture within an organization. Leaders must be equipped with the skill set to not only implement Lean but to sustain it through a deep understanding of its principles and methodologies. Only by focusing on process and supporting each other in this methodology can an organization truly realize the full potential of its Lean management system.

Enhancing Leadership Through a Lean Mindset

The early successes or failures of Lean management often hinge on the attitudes and behaviors of supervisors and managers. Leadership plays a pivotal role in either fostering a culture of continuous improvement or stifling the lean journey before it gains momentum.

Transitioning Supervisors: Shifting from Punitive to Inquisitive

Embracing a lean philosophy requires supervisors to shift their management style from punitive to inquisitive. Punitive leadership focuses on assigning blame when things go wrong. By contrast, inquisitive leadership encourages supervisors to delve into the root causes of problems.

For supervisors to facilitate continuous improvement successfully, they must:

- Replace the instinct to “jump down someone's throat” with a composed approach that seeks to understand the issue by asking “why.”

- Encourage their teams to identify not just the problems, but also their causes, and possible solutions that may prevent recurrence in the future.

A real-world example of such a transition involved a supervisor who returned from a break to find his production area in chaos. After attempting to rectify the situation single-handedly for several days, his manager suggested he stick to his standard work. This advice refocused the supervisor's efforts, and quickly brought stability back to the production line. The supervisor became a firm believer in following standard work protocols as a means to maintain control and instill process discipline.

Creating Robust Systems over Heroic Efforts

The Lean model favors systems and structures over individual heroism. Incident analysis at one manufacturing company revealed that a breakdown in process — such as machines malfunctioning — was triggering unsustainably heroic behaviors among supervisors. One supervisor even drove for miles to procure parts for repairs, an effort which was commended but was ultimately a symptom of a flawed process.

To counteract this, places such as upholstery areas now have:

- Designated zones with backup equipment for ready replacement to maintain production flow instead of makeshift solutions.

- A focus on process reliability and efficient response to common issues rather than ad hoc troubleshooting.

This approach underscores that solving systemic issues is more productive and sustainable than sporadic acts of individual bravery. Manufacturing personnel, who are quite pragmatic by nature, have shown great openness to adopting measures that effectively stabilize and streamline processes once they see them in action.

Determining The Suitability of Supervisors for Lean Leadership

A crucial part of integrating Lean leadership is evaluating supervisors' ability and willingness to embrace new ways of thinking. When the expectations are made clear, it becomes easy to monitor compliance. Supervisor conduct should be assessed to ensure:

- Proper training

- Clear understanding of expectations

- Availability of appropriate tools and materials

- Receipt of actionable feedback on their performance

This evaluation method becomes highly effective in a lean-focused organization, where the management system mirrors the production system in its process-dependence. Typically, within a few weeks, it becomes evident who is willing to adapt to the new culture of Lean and who is not. Supervisors' performance should ideally be measured by their adherence to process, rather than solely by outcomes, as consistent process adherence will naturally lead to desirable results.

Realities of Lean Leadership During Adversity

The reality of implementing Lean during tough economic times can be harsh but telling. The recessions of the early 2000s tested many companies. At companies like Steelcase, leaders noticed that those who remained in managerial positions after significant downsizing tended to be those who truly embraced Lean — not merely by paying lip service but by actively engaging with Lean principles to maintain efficient operations.

Despite being difficult, this natural selection of sorts highlights a critical point: true Lean leaders not only survive but thrive during adversity through their genuine commitment to the principles and practices of Lean management. Their ability to keep Lean systems functioning becomes an invaluable asset to the organization.

The development of a Lean culture is a journey with many facets. One of the pivotal factors lies in the transformation of supervisors from traditional command-and-control figures to leaders who support, guide, and improve processes together with their teams. Leaders embracing a Lean mindset will likely discover that their organizations are more resilient, adaptive, and, ultimately, more successful in the long term.

Fostering Growth Through Learning from Mistakes

One of the most vital yet overlooked aspects of Lean leadership is the ability to learn from mistakes. Traditional business culture often punishes errors, but a Lean mindset values them as opportunities for growth and innovation. Leaders need to cultivate an environment where mistakes are not hidden or shamed, but openly discussed and used as a platform for learning.

To achieve this, leaders should:

- Establish trust within teams, ensuring that employees feel safe to admit errors without fear of retribution.

- Lead by example by owning their mistakes and demonstrating the learning process.

- Provide training and resources focused on problem-solving and critical thinking skills.

By embracing mistakes as part of the learning process, organizations can innovate more effectively. This is because a culture that hides mistakes is also one that stifles creativity and risk-taking, which are essential components of innovation.

The Role of Reflection in Lean Leadership

Reflection is another core principle within Lean thinking which facilitates a deeper understanding of mistakes and successes alike. Regular reflection sessions can empower teams to proactively identify continuous improvement opportunities.

To incorporate reflection into Lean leadership:

- Schedule regular meetings dedicated to process review and open discussion.

- Encourage team members to share their thoughts on what is and isn't working.

- Use structured methodologies, like After Action Reviews or the 5 Whys, to guide reflective practices.

Integrating Audio and Visual Learning Tools

The recent release of audio books like “The Mistakes That Make Us,” underscores the relevance of diverse learning tools in Lean initiatives. In multimodal learning environments, employees have access to knowledge through various formats – audio, visual, and kinesthetic. This multimodal approach can cater to different learning styles and reinforce Lean principles.

To integrate these tools, organizations should:

- Provide access to a library of resources, including books, audiobooks, podcasts, and videos on Lean topics.

- Encourage employees to consume content in whatever medium suits them best.

- Facilitate group discussions on insights and lessons gleaned from these resources.

Embracing Technological Solutions

In the digital age, technology can significantly support Lean leadership in managing processes and facilitating continuous improvement. Software tools can track production metrics, manage workflow, and automate standard work procedures allowing leaders to focus on strategy and employee development.

Effective technology integration might involve:

- Implementing process management software to enhance visibility and control.

- Utilizing data analytics to objectively assess performance and identify trends or anomalies.

- Offering digital platforms for training and communication to streamline knowledge sharing.

The Crucial Element of Adaptability in Lean Leadership

Finally, Lean leadership calls for adaptability–the ability to change course when necessary. This trait is particularly important in times of rapid change or unforeseen challenges. Leaders who are adaptable can navigate disruptions while still maintaining Lean principles and processes.

Adaptive Lean leadership should incorporate:

- Frequent reassessment of goals and strategies to align with current realities.

- A willingness to experiment with new processes or technologies.

- Emphasizing the value of flexibility and change-readiness across the organization.

In conclusion, Lean leadership requires a nuanced combination of strategies, including learning from mistakes, promoting reflection, integrating versatile learning tools, leveraging technology and nurturing adaptability. These competencies enable leaders not only to support their team in the present but also to lay the groundwork for a resilient and innovative culture that can stand the test of time and challenge.

Automated Transcript:

Announcer:

Welcome to the Lean Blog podcast. Visit our website@www.leanblog.org now here's your host, Mark Graban.

Mark Graban:

Hi, this is Mark Graban. Welcome to the podcast episode 212 for January 2, 2015. Today's episode is one that I recorded back in October with David Mann, and we're talking about his newly available third edition of his great book, Creating a Lean Culture. I apologize for the hiatus and for the delay in getting this released. Apologize to David and to the listeners.

Mark Graban:

In November and December, things got very busy for me. I was in Japan. I was in the Netherlands doing a lot of great travel and work around the United States, and podcasts kind of fell to the back burner. So again, sorry about that. But I do look forward to creating more podcasts, more discussions here in 2015 so you can learn more about David's book.

Mark Graban:

See a video, find links about how to purchase the book@markgraban.org. 212. And I want to wish everyone a happy new year. Well, David, hi. Thanks for being a guest again on the podcast today.

David Mann:

Hi, Mark. Thanks for having me back.

Mark Graban:

If you can believe it, it's been almost exactly eight years since we did a podcast together talking about Creating a Lean Culture, your book and all the topics associated there. And I think back then we were probably talking about the original first edition. Is that right?

David Mann:

Yeah, right. That would have been that time.

Mark Graban:

So I would encourage people to maybe go back and listen to episode nine. Leanblog.org nine will take people there. But since then, there has been a second edition, and you're currently working on the third edition. So I was wondering if you could talk to the listeners about maybe in general the progression of the book and what's changed and what you've learned and how this new third edition is going to be different.

David Mann:

I'd be happy to do that. Yeah, the third edition is done. It's at the printer right now, and it's scheduled for release later this month. On October 29 is the date. I think it's orderable now, but the physical copies won't be until October 29.

David Mann:

The progression has been really interesting, and it's been sort of my own version of a lean journey in going back over the original and then the second edition to produce the third and then going through the final steps of publication are there's a lot of proofreading back and forth and sort of poring over it. And I realized that there was a lot that I had learned about what I first wrote about in Creating a Lean Culture. There was a lot that I had learned about the content of that first version over the intervening eight or nine years. So this may sound funny, but I discovered there was more than I had realized than when I put it on paper the first time. And some of that has been, a lot of it actually has been based on just working in the field and first internally and then over the last seven or eight years, getting the opportunity to see lots of organizations that have been working at implementing the material in the book, the lean management system and the different ways that they have gone about doing it.

David Mann:

That would never have occurred to me, frankly. And one conclusion is there are a lot of ways to do it right, and the other is, so what more meaning is there in terms of standard work for leaders in the sequence of implementation, the applications of lean management in non manufacturing settings, and then more recently in the last several years, particularly an issue that concerns, as it turns out, lots of internal lean leaders, and that is that even though they're working with the sponsorship of senior executives, they have a very difficult time. That is, the lean leaders have had a very difficult time getting the senior executives actually involved, not just interested in, but actually involved in the lean initiative. And in the absence of that involvement, there's risk for the continuing support for a lean initiative. Senior leaders are prone, like many of us, if they're not involved in something, to have their attention, drift to something else and wake up one morning and discover that now there's a new initiative that sort of sounds like what we've been doing, but is fundamentally different in pretty important ways.

David Mann:

It's a different level of missing link. It's more a strategic missing link for sustaining lean. The lean management system, as originally laid out, has proved good at filling in a gap at a tactical level. But having seen that tactical level tightened up, then another issue emerges, just like you Kaizen, and see things improve and change, and then all of a sudden problems arise that were apparently hidden in plain view. But until the improvements of the kaizen were put in place, those later issues, later problems just simply weren't visible.

David Mann:

So now there's this strategic disconnect, if you will, or a disconnect between the strategic level and the tactical level. And some of that plays out in how you understand standard work for leaders, when standard work for leaders now involves senior executive staff members. So what is it that we want them to do? And when they do what we ask them to do in terms of standard work, what does that teach them about lean? Or is it just another sort of check the box exercise for them that they do for a while, and if they're not getting much out of it, they may stop or they may continue it, but that is continue following this standard work, but it actually is more of a compliance activity both for them and for the parts of the organization to which their standard work takes them.

David Mann:

So more of a compliance activity than an improvement activity or a development activity.

Mark Graban:

Right.

David Mann:

So that's been particularly interesting.

Mark Graban:

Yeah. Maybe delve in a little deeper into some of the points you made there when you talk about maybe for one, and we'll delve deeper into leader standard work as a topic. But when you talk about a compliance mentality that seems to not be keeping really in the spirit of lean, I think maybe that's one part of the, is that part of the awkward transition from organizations that have had maybe a more traditional culture that is more top down or more compliance based, and now they start trying to layer some lean methods on top of that. Is that one of the difficulties when you see maybe a mismatch between a mindset and a method?

David Mann:

I think that's a fair way to characterize it. And in terms of organization structure and organization process, the majority of them that I see anyhow are, they're sort of classic vertically oriented organizations where direction comes from the top. So top down is pretty common. I mean, most of us who work in organizations work in hierarchical organizations. Some are more flexible than others, but hierarchical structure is going to be, is going to be pretty common.

David Mann:

So that there are. So the, so the issue is pretty widespread, I guess I'd say.

Mark Graban:

Yeah.

David Mann:

So the, the, it, the intent of leader standard work, it seems to me, is to guarantee the integrity of the standardized lean production process, whatever that underlying process is, where at the task level there have been lean applications and lean design, and the integrity of that process relies, it seems to me, on an understanding of why we're doing things the way we're doing. For me, the integrity of a lean process includes an understanding that lean is most fundamentally an improvement process. And so we're doing these lean applications to improve. And that improvement is something that is continuous until you reach a point that true north point, the way Toyota talks about it, where basically there is zero non value added activity in the process, which is a very long stretch that I don't know. I haven't seen that mark.

David Mann:

I don't know if you have either. It's a goal that sort of is always out there in front of you.

Mark Graban:

So one other question I would have for you, David, before maybe diving in deeper, we mentioned other industries. I'm curious to hear about some of your work and the new content in the book, because I think back even to the first edition of Creating a Lean Culture. I've given that book to a lot of healthcare leaders, and I think even though a lot of it was perhaps based on your work at steel case and manufacturing environments, healthcare leaders found that book incredibly helpful. But the book has sort of evolved to include, can you talk about some of the work and examples from other industries.

David Mann:

So I've been fortunate at the last several years to have gotten around a lot, spent a bunch of time on the healthcare side, hospitals, physician practices, clinics, as well as some of the ancillary support activities that go on with healthcare. At the same time, in fact, literally at the same time, for a period of about a year and a half, I was also working in process industries, in the energy industry, heavy maintenance, in process industries, and a bunch of other from low tech manufacturing, metal forming, and then up into precision machining, engineered materials technology, manufacturing, aerospace, and that kind of thing. Food processing, whiskey bottling. It's very interesting working in a whiskey bottling plant.

Mark Graban:

Yeah.

David Mann:

If you work in the lab, that means you show up at 06:00 in the morning and you're tasting samples anyhow, so the world is an interesting place. The principles of the book, across its several editions, are unchanged, but the lessons from application are the things that have evolved. One of the ideas that has sort of come to the surface for me over that period of time is the idea of the value proposition of the lean management system from the point of view of people that we're asking to participate in it, to use it, whether they're frontline staff people, first level leaders, or all the way up through the organization and in the hierarchical organizations, the way most are the structured that you find most commonly when you go up into the hierarchical organization. For example, asking executives to, and this would be actually most common in hospital settings, asking executives to round or to have their own standard work that gets them out to often frontline work areas, or the visual centers or team centers where employees huddle, or where metrics are tracked and updated on often a daily basis, in some cases a weekly basis, that their standard work will take them out to those areas. And rounding in healthcare, of course, is something by physicians and it's done by chiefs.

David Mann:

It's a very good example of the master apprentice model for learning and teaching when you're rounding in a clinical education setting. But what I see most often, so these would be administrative executives rather than the senior, most clinical leaders, although sometimes there as well. The rounding seems to be more a compliance feeling activity than a learning and teaching activity.

Mark Graban:

Right.

David Mann:

That's, I think, a critical distinction, and it's one that, while I think the clearest illustration of that distinction is visible in healthcare, in part because there's more of it. The lean influences in healthcare, including yours with, I think, very good reason, said Gee, we need to have the support for sticking with the discipline of the lean applications all the way down the organization. I think that's a positive thing. I think that's a well founded thing. But coming back to what we were talking about a couple of minutes ago, if the intent of standard work is to guarantee the integrity of the standardized lean production system at the value adding level, at the frontline level, part of the integrity of a lean system is that it is focused on continuous improvement, that it recognizes that even after improvements have been made, imperfections remain.

David Mann:

And those imperfections are often not visible until a layer of improvement happens and the previous problems have now been eliminated at a root cause level. But that allows you to see other problems that previously were in disguise, were hidden.

Mark Graban:

And I think when people are too compliance focused, they are focused too much on, well, here is the standard work. You need to be following it as opposed to, well, we should be following it but also improving it. And I've seen a lot of times what looks like somebody not following the standard work is actually somebody in the middle of Kaizen. They might look very similar. And the compliance mindset stifles the improvement work, which, as you're saying, is something we don't want to see happen.

Mark Graban:

Right?

David Mann:

Exactly. And from the point of view of the executives who are dutifully, they have their standard work and they go and they're basically doing auditing. Are there measures on the board? Yes, there are measures on the board. Are the measures the data displayed, is that up to date?

David Mann:

Yes, it's up to date. Does the board have the appearance where there is an emphasis on standard boards, does it look right? Is there evidence that people are meeting and it's very much like it's a checklist, and there's nothing wrong with checklists per se, but if I'm checking boxes, I'm checking boxes that typically would be based on the surface of things. It doesn't have a lot of meaning, I think, for executives because they have a difficult time connecting that with their responsibilities. And their responsibilities for the lean initiative are different from the responsibilities of people like us who worry about the nuts and bolts of the lean implementation itself and how those nuts and bolts are working and where they might need to be tuned.

David Mann:

The executives had, I think, sort of taking a step back, which we had to do several years ago because we were in a position of losing the support of our executives. This is when I was working internally at steelcase. The executives are responsible. This was our conclusion, sort of taking a step back and saying, well, how come we're losing the support of people who initially were our sponsors, right? And how should we understand them?

David Mann:

And we sort of took some of our own advice, which we had not been following, which was to look at our executives as our customers. Previously, we had been thinking of them. They were basically, we decided that they were going to be our apprentices and we were going to teach them lean the way we learned lean, by sort of dunking them deep into the lean tool application. By George, that's the way you learn lean. Well, that's true if you're willing to learn lean because you're trying to learn how to be an implementer or how to sustain the things that have been implemented in your area and what further applications for improvement you can see.

David Mann:

But executives aren't interested for the most part in being lean implementers because, again, they got people like us to worry about that.

Mark Graban:

Well, maybe for good reason. I see this, and I find myself saying sometimes say, well, we want to implement lean. And I say, well, I try to say it in kind of a cheeky way, like, well, who cares, right? But if we want to improve safety, not harm as many patients, improve quality, improve the workplace, those are all noble and important and meaningful goals that lean and a lean management system can help us accomplish. Right?

Mark Graban:

When you talked earlier about the value to executives or how else would you articulate that?

David Mann:

Well, the value proposition is, interestingly, I mean, the value proposition is not very complicated. The value proposition basically answers the question, well, why should I do this? What's in it for me? And if I'm a phlebotomist, and what's in it for me in a lean application might be that when I show up in the room, the patient's there instead of am I having to try to find them for a supervisor in any kind of organization? That could be a supervisor in a call center could be a supervisor, a nurse manager, could be a supervisor in a physical production facility, but pretty much anywhere.

David Mann:

The value proposition for a supervisor is, gee, we put these lean tools in place and it eliminated some problems that were sources of chronic aggravation for me. And so what's in it for me from lean is these chronic aggravations have gone away. The value proposition for the lean management system is if we do these pretty straightforward things in the lean management system, the problem won't come back because you'll be sustaining the lean production process that we've put in place. And as a bonus, the lean management system is going to bring to the surface further opportunities for improvement. So not only do you sustain the initial gains that you got from the lean tools, but you actually are then able to take advantage of these further opportunities for improvement that come up from close focus on the process and tracking the deviations from what you expect and thinking of them as opportunities for improvement, and then using what you've learned about lean to to make still further improvement.

David Mann:

So the value proposition is it's keeping the solved problems from coming back and it's using the process to identify for you other opportunities to make further improvement. So that's pretty good. And if you're at a line level, whether frontline or line management, up to maybe a department administrator or a plant manager, it depends on your structure and industry. But if you've got tactical responsibilities, the lean management system is going to help you with sustaining the improvements in your tactical processes and benefiting from further improvement. But if you're an executive, you don't have tactical responsibilities anymore.

David Mann:

You have strategic responsibilities. And even if you came up through the operations side of your organization, even if you have a technical background, let's say you went through three years of calculus to become an engineer, but those aren't your responsibilities anymore. And it's not that you're not interested in them in most cases, but you have other, much more pressing things to worry about. The things that wake you up at 03:00 in the morning are not problems that your technical background is going to be all that helpful in solving. By contrast, when you're an executive and you've signed up for a lean initiative in your organization, in your facility, in your plant, in your hospital, in your department, you have responsibility for that initiative.

David Mann:

You've signed up for lean because you also have year on year improvement goals, and you've signed up for lean as a way of reaching those goals. So you've got responsibility for the initiative at a much broader level and directly related to that, you have responsibility for the integrity of your chain of command, executing the lean initiative all the way down through the front line, because that's where those benefits are going to come from. So the reason that I think makes more sense to executives, because it addresses the value proposition for them, is that the reason to go to the front line is not to do a box checking exercise to make sure that everything looks right.

Mark Graban:

Right.

David Mann:

But rather to have the conversation with frontline people and with first and second level leaders to assess whether they understand what they're doing. So why are we doing lean? Tell me how these tools have worked for you. Can you give me an example of how they've been beneficial? How do these boards work?

David Mann:

How do these visual controls work? Have they helped resolve problems that have come up? So you're asking those kinds of questions, often explicitly, and you're also making observations. Gee, the board looks nice. But is there any evidence of improvement that I can see that's related to these things that are displayed on these visual control centers?

David Mann:

So the reason to do this as an executive is pretty straightforward when framed this way, and that is that if people at the front line tell you, and I've heard people have told me this, yeah, I know we've got these boards up here and these charts, but I've been putting problems that I run into in my daily work. I've been putting problems on these charts for six months and not darn things ever happened with them. So I guess you're asking me how I like the chart. I guess I'm done with this chart. This is just signs and lines.

David Mann:

This is just some bureaucratic stuff that was somebody's good idea, but it's not really doing anything for us. It's a waste of my time. If you hear that, red light should be going off in your head and not in a way that says you should chew out whoever it is you're talking to or go find their supervisor and chew them out, what you're seeing is evidence that between you and this frontline person is your chain of command. And someplace in that chain of command, there are broken links.

Mark Graban:

You're saying chain of command with command. That's a different phrase from a different era. It seems kind of out of place in an environment you're describing, where it's about leaders learning and teaching and working together. They're within the leadership chain.

David Mann:

Yeah. So chain of command, not in a negative way, in your worst nightmare, if I'm a senior executive, but if I'm a senior executive, there's an organization I'm responsible for an organization in which there are multiple levels, five, six, something like that. And that's my organization structure. So if you think about chain of command in a Hoshin Conrad kind of context or in a strategy deployment context, the strategy gets deployed down through the levels of the organization and supporting the application of the strategy. So the lean applications here at the front line levels, and when I go to the front line and the front line tells me this stuff really doesn't mean anything to me and it's not really helping, there's a lack of understanding and there's a lack of effectiveness.

David Mann:

The problem is not the person telling you this, and the problem probably isn't their supervisor, but rather the problem is someplace embedded in your organization structure, down through your subordinate executives, middle managers line leaders, down to the front line. That's a managerial responsibility that as a senior executive, you're the only one who can do anything about it. So you've got this managerial responsibility for the integrity of your chain of command, and you've got this strategic responsibility for the effectiveness of the lean strategy or whatever other strategy. Doesn't necessarily have to be that, but we're talking about lean. So you've got strategic responsibility because you've endorsed the lean initiative to produce the benefits that the organization expects you to produce.

David Mann:

And so strategically, from your strategic responsibility, you need to make sure that the strategy is being faithfully executed down through your organization. And from a managerial perspective, you want to make sure that there's integrity in your organization so that decisions about strategy that you've arrived at, one hopes, with your team are actually being supported as you go through the rungs, the levels in your organization. So the strategy is being commonly understood, explained and reinforced all the way down to the point where the actual benefit gets developed, gets produced, which is at the front line. So you can have a conversation with your executives explicitly in those terms, or the executives probably are going to understand it without a lot of coaching. That leader standard work for executives, seems to me, is to go test for the integrity of the system, of your system of organization and the effectiveness of the strategy, that it's actually being deployed at the front line, and that it's actually producing benefits that people at the front line can describe to you and that in many cases, you can see for yourselves.

David Mann:

That's very different from looking at a highly distilled report of activities or somebody's version of dollar cost savings or what have you. It's not that those reports are bad things, but in the absence of really going to where you can look and see and listen and learn and touch them, you shouldn't really be confident that those reports are reflecting that all the things that you want to be happening are happening, right. So you want to reinforce those things. And the way to reinforce it is to go see so that would be the same in any organization. But go and see and have those conversations with the frontline people.

David Mann:

The classic decoding the DNA of the Toyota production system. That Harvard Business Review article from the don't remember exactly. I don't know exactly the year, but what's the process here? Those classic questions. What's the process here?

David Mann:

How can you tell it's working? What do you do when it's not working? Is there work going on to improve it? There are variations on those questions, but they expand the intent so that they form the framework for observations and conversations at the front line. And that's a lot more meaningful than walking around with a checklist and check, check.

David Mann:

So I've checked my checklist every week for the last six months, and it's not really clear to me what I'm getting from that. Is it worth my time to do this? What we found is the answer is, well, not so much. I'm complying. I'm being a good soldier, but I've got responsibilities that this checklist doesn't help me with.

David Mann:

So the value proposition for a senior executive is, yes, this helps me with my responsibility for maintaining the quality and tone of my organization, and it helps me with evidence of where improvement is actually happening and that I'm confident that we're going to get the results that I promised my board of directors.

Mark Graban:

Right. Well, maybe one other question. Ask before we wrap up. I think you do a good job of spelling out the dangers of applying a practice like rounding and taking maybe an overly mechanical view of, well, this is the checklist that I saw some other organization use, and here's the timing and kind of just checking through the what to do. But I think there's deeper questions of, as you're bringing up, well, how you do it, how you're behaving, that's harder to put into a checklist.

Mark Graban:

Usually these checklists don't say ask two non judgmental, open ended questions of inquiry. It's not that directive, but that's probably what we'd hope to see people doing. I'm curious from your perspective, since your background is social science and curious, your thoughts on changing behaviors. If there's a senior leader you're working with who says, okay, I want to do this, I want a lean management system for these benefits that we've discussed and for these reasons. But I've been doing it this old way for 30 years, from when I was a frontline supervisor, perhaps all the way up to being a plant manager.

Mark Graban:

How realistic is it? Or what do you do to try to help somebody change fundamental mindsets or underlying behaviors? Somebody goes out for rounding or a gimbal walk, and they see a problem and they leap to blame a person. What hope is there of somebody wanting to change or effectively changing in the context of this management system?

David Mann:

Well, I'm glad you asked that. That's an important question. The problem starts with our assumption that executives know how to do this, that they know how to round or gamble walk in ways that will pay off for them, the value proposition stuff. And stop and ask yourself, why should any executive know how to gamble, walk or round from a lean perspective if they have never had any contact with lean before? Right.

David Mann:

They don't know. We assume that they know because they have these high positions, but they don't know. So come back to Gembawalk as a learning and teaching process as opposed to a compliance process. What I've done, both internally and externally, is to think about a gemba walk as a repeatable process. That's not going to surprise.

David Mann:

Your executive is going to allow the executive to be prepared to find the answers to the kinds of questions that we've been talking about, the questions of not just of compliance, but understanding and effectiveness. So before sending your executives out to gamblewalk, what I recommend is you gamble walk with them. We've reformatted a lean management standard assessment. It's a dimension by dimension. So an example would be an assessment would be assessing visual controls or standard accountability processes, or assessing leader standard work.

David Mann:

So each one of those assessments is, it's a one page document. It's got some diagnostic questions on it, five or six diagnostic questions, a brief statement of intent, and a rating scale. And so this repeatable process, turning the gembawalk into a repeatable process, so the executive understands what she's going to be asked, what it is that she's supposed to do, that she's prepared to lead the Gemba walk herself because she's responsible for her own learning. So we meet the lean resource, you or I or one of our colleagues in the organization hands the executive the gembox. So we're going to look at visual controls today.

David Mann:

Okay? So I understand what it means, because I've been around this block before, gamba walking. So I look at this one pager. You've highlighted three of the diagnostic questions. This is what we're going to focus on today.

David Mann:

So questions for you to answer, and we're going to go out to such and such an area, and you've talked about. So I'm here today with Mark, but I'm really here as a student, and you all are the teachers. You've been doing this lean stuff. So I need to get the answers to a few questions here. So you sort of set people at ease.

David Mann:

So your executive is then is leading the conversation. You or I might ask a leading question if we want to steer things in a particular way. But the executive is responsible for her own learning here, getting the answers to the questions, we then, as we're walking off the floor, you ask the executive the critical question, because the one pager has a five point rating scale on it. Self describing five point rating scale. So how do you think they did?

David Mann:

And if it's the first time, the executive might say, well, they had the boards up there, and the boards looked pretty good, and they were neat, and the measures looked like they were current. I'd say this five point scale I'd give them. I'd say they're maybe like three and a half, maybe even higher. And you say the socially appropriate equivalent of, oh, David, no. Good, because she's not seeing what you're seeing.

David Mann:

And the idea of the gamble walk is to see what your teacher sees. And that would be true in a clinical gamble walk. It's certainly true in a lean gamble walk. So your executives, if they're like all the executives I've ever encountered, they're very bright, they're quick studies. They're extremely competitive, highly achievement oriented.

David Mann:

These are the people who got an a on every test they ever took, and that's part of that. Competitiveness and achievement oriented. They're action oriented. So they like being in charge of their own gamble walk. They want to be prepared, have a little bit of staff work, and that's what the one pager does, because they want to feel comfortable, confident and competent when they're out doing something that shows up on their calendar.

David Mann:

Now it's time to go to this place and do this thing with these people. So you've prepared them for all of that. The test really hooks them. The test is you think they're a low two and they think it's a high three. When you let them know that they haven't passed the test, you've opened about a 92nd teachable moment for them, and you quickly say, well, this is what I saw.

David Mann:

Yes, the boards were up to date, but when we asked people about them, they sort of hemmed and hawed, and they didn't really give us the sense that they knew why they were doing this, and they weren't able to tell us how things had improved as a result of using these boards. Oh, okay. It's teaching a different behavior. So an alternative positive behavior to simply checklist rounding it makes it personally meaningful. They want to get an a on the test, and they can very easily get the sense without that being even an explicit topic of conversation, that I'm being told one thing about how effective lean is here.

David Mann:

But my observations suggest maybe not so much. Maybe if I'm an executive, I might ask one of my lean resources, who do you think I should gamble walk in my organization? Because now the managerial responsibility is assessing. So where is the weak link in my organization? And I'm going to go gimbal walk them, because after doing this one or two times, maybe three, on something like visual controls and the other elements of lean management are equally straightforward.

David Mann:

I'm going to be able to go gimbal walk one of my subordinates someplace in my organization, and I'm going to be able to tell whether he or she understands what we're trying to do here. And it's then my job to do reset expectations, do some coaching, and expect to see things to improve as I'm gimbal walking in the future. And if they don't improve, then I've got a whole other kind of problem, a performance issue in my organization. I know how to deal with those things so that, so the, because it's a process that executives quickly are comfortable with and they see how it affects the things that are important to them, that are meaningful to helping them do a better job. It's pretty effective pretty quickly.

David Mann:

You do this several times and people are able to do it themselves comfortably, and they see the benefit, they experience the benefit from doing it.

Mark Graban:

Well, good. Well, I hope the discussion and the new book helps people forward in that process. Creating a Lean Culture third edition coming out. You said October 29?

David Mann:

Yes.

Mark Graban:

As much as the publishing value stream is predictable, hopefully that date holds. People can find it. It is available for pre order on Amazon. Productivity Press is the publisher, so their website has it. And David, tell the listeners what your personal website is if people would like to reach out and maybe talk to you or learn more about your work.

David Mann:

Oh, yeah, it's dman Lean, all one word. Dmanlean.com man has two ends, and I did a brief video describing what's new in the book, basically, and the website information is on the screen at the end of that video, too.

Mark Graban:

Okay, great. And I'll make sure that video is embedded in the episode page for this podcast over on the blog, which can be found@markgraban.org 212 so yeah, encourage people who are listening to this in their cars or out for a walk or something. Go back to your computer, come to the website and watch that video. Learn more about David's book. So I'm real excited that this new edition is coming out.

Mark Graban:

Congratulations on that, and thanks for taking time to talk with us today.

David Mann:

Thank you, Mark. Always a pleasure. Thanks for listening. This has been the Lean blog podcast for lean news and commentary, updated daily. Visit www.leanblog.org.

David Mann:

If you have any questions or comments about this podcast, email mark at leanpodcast@gmail.com.

Announcer:

Hey podcast listeners. I'm excited to announce the release of the audiobook version of my new book, the mistakes that make us cultivating a culture of learning and innovation. Listen and dive into powerful insight on fostering growth through mistakes. Whether you're a leader, entrepreneur, or just trying to get better at learning from mistakes, this audiobook is for you. Get it now on audible, Amazon, and Apple books.

Announcer:

Visit mistakesbook.com for more info.

Article About the Episode:

Creating a Culture of Continuous Improvement with Lean

Understanding the journey of Lean methodology adoption in organizations requires a closer look at its evolution, practical applications, and the challenges faced by leaders striving to create a Lean culture. While the discussions surrounding Lean often focus on manufacturing, its principles and practices have permeated a range of industries including healthcare, aerospace, and even food processing.

The Evolution of Lean Culture

When we talk about the progression of Lean culture within an organization, it's essential to address how literature and thought leadership have driven this evolution. Originating from the Japanese automotive industry, the concept of Lean has taken on a global significance, necessitating a continuous refinement of its application and understanding. The idea isn't to merely implement a set of tools or processes; it's to foster a mindset of ongoing improvement that transcends all levels of a company.

Over the years, books and resources that delve into the Lean management system have expanded upon these ideas, highlighting the importance of adapting Lean principles to meet the unique challenges of different organizational environments. It's no longer just about the manufacturing floor–Lean is now just as relevant in a hospital as it is in a whiskey bottling plant. The core principles remain unaltered, yet how they are applied, taught, and sustained evolves with each new setting and experience.

The Role of Leaders in Lean Initiatives

A critical piece of the Lean puzzle is leadership involvement. The Lean management system has proven effective at addressing tactical gaps, but a strategic disconnect can emerge if leaders, particularly senior executives, are not truly engaged in the Lean initiative. Their engagement is more than just an endorsement–it's about participation, understanding, and a commitment to sustaining Lean processes.

The concept of Leader Standard Work is pivotal here. It is not just a checklist of activities for leaders to accomplish but a framework that guides leaders into regular interactions with Lean processes, ensuring the integrity of these practices. The challenge, however, is to avoid turning Leader Standard Work into a mere compliance exercise. Instead, it should be a vehicle for leaders to learn, teach, and cultivate an improvement-driven culture.

Lean's Application Across Industries

As Lean methodology has matured, so has its application across various industries beyond manufacturing, such as healthcare, energy, and food processing. Lean isn't a rigid set of practices but rather a flexible framework that can be adapted for diverse operational environments. The success stories from these sectors are testaments to the universality of Lean principles when thoughtfully applied.

For example, in healthcare, Lean principles like 'rounding'–where leaders regularly visit front-line areas to engage with staff and processes–are gaining traction. While rounding has its roots in clinical practice, it serves an equally crucial function when performed by administrative executives. The goal is to make these rounds more than a procedural task; they should be profound, reciprocal exchanges of knowledge and insights focused on improvement.

In every industry, the principles of Lean should be perceived not only as efficiency maximizers but also as value propositions for all organizational members. The idea is to ensure that everyone, regardless of their position, understands the rationale behind Lean practices and sees the benefit of participating in this culture of continuous improvement.

Overcoming Compliance Mentality to Embrace Improvement

One of the ongoing themes in the development of Lean culture is tackling the inherent compliance mentality that may contradict the philosophy of Lean. Organizations traditionally built on hierarchical, top-down structures may experience friction when attempting to integrate Lean methods that encourage autonomy, innovation, and involvement at all levels.

To successfully transition to a Lean culture, there must be alignment between mindset and method. This requires a shift in leadership perspectives and behaviors. It's not enough to simply superimpose Lean tools onto existing frameworks; it demands an organizational transformation where Lean thinking permeates the entire strategic and operational approach.

As Lean continues to evolve, the key is to ensure that the entire organization, from frontline employees to the C-suite, understands and embraces Lean as a continuous journey rather than a static destination. This alignment will not only sustain a Lean initiative but ensure that as problems are solved and improvements are made, new opportunities for growth are always in sight.

Encouraging a Problem-Solving Mindset

Moving beyond compliance and checklists, the essence of a true Lean culture lies in its ability to instill a problem-solving ethos throughout an organization. This ethos not only encourages adherence to standard work but actively promotes constant questioning and reevaluation of processes. Engaging in problem-solving as part of the daily routine enables employees at every level to identify issues and develop innovative solutions.

The Shingo Model reinforces this by stating that behavior grounded in correct principles is key to creating sustainable results. To this end, training programs and workshops can be employed to teach employees the principles of Lean thinking and problem-solving techniques. Cultivating this mindset takes time, but the payoff is a workforce that's not only following procedures but is also vested in improving them.

Expanding the Scope of Kaizen

Kaizen, or continuous improvement, is central to the Lean philosophy. However, expanding the scope of Kaizen beyond the immediate tasks at hand to strategic business objectives is crucial. This entails aligning daily Kaizen efforts with the long-term vision and goals of the organization. Continuous improvement should not be seen as isolated events but as stepping stones towards achieving broader organizational excellence.

Senior leadership must demonstrate how tactical improvements contribute to strategic initiatives, ensuring that individual contributions are recognized within the context of the company's overarching mission. This alignment fosters a sense of purpose and drives engagement at all levels of the organization, making continuous improvement both personally relevant and strategically significant.

Visual Management and its Strategic Value

Visual management tools, such as control boards and performance charts, are more than just mechanisms to display data. Executives and managers should use these tools to initiate meaningful dialogues with teams about the performance indicators. These conversations should focus on understanding the data's implications, celebrating successes, and exploring opportunities for further improvements.

When executives engage with front-line employees through visual management, they validate the importance of the data and the employees' role in the organization's success. This acknowledgment can have a profound impact on morale and ownership of the processes. By fostering a climate that values observation and dialogue, executives create an atmosphere in which continuous improvement thrives.

Lean Leadership Development

To ensure the Lean journey is effective, leaders themselves need to embody Lean principles. This requires a commitment to ongoing education and professional development. Programs for Lean leadership development should focus not only on the technical aspects of the Lean tools but also on the soft skills necessary for cultural transformation.

These programs should be designed to help leaders at all levels understand their role in supporting and promoting a Lean culture. This includes knowing how to mentor employees, provide constructive feedback, and encourage collaborative problem-solving. Through leadership development, organizations can nurture a cadre of leaders equipped to sustain and advance Lean principles and practices.

Levering Technology in Lean Transformation

Technology can play a pivotal role in accelerating and sustaining Lean transformations. Data analytics, automation and advanced software solutions can streamline processes, eliminate waste, and provide better visibility into operations. However, the introduction of technology must be done with careful consideration of Lean principles. Technology serves as an enabler for Lean, not a replacement for the human elements of problem-solving and continuous improvement.

Organizations can leverage technology to support Lean initiatives by providing real-time data, facilitating communication, and enabling better decision-making. Tools such as predictive analytics can identify potential issues before they arise, allowing teams to proactively address them within the Lean framework. The key to successfully integrating technology with Lean lies in ensuring that it enhances, rather than detracts from, the core objective of adding value to the customer.

By weaving these themes into the fabric of an organization's culture, Lean transcends being merely a set of tools and becomes a way of thinking that drives excellence, efficiency, and value in all facets of the business.

Importance of Frontline Engagement in Lean Transformation

The importance of executive engagement with the frontline workforce cannot be overstressed when it comes to a successful Lean transformation. Executives should regularly visit the frontline, not just to observe but to engage in meaningful conversations about the work being done. These Gemba Walks–where leaders go to the actual place where value is created–allow executives to validate systems and strategies, assess whether they deliver tangible benefits, and gauge whether improvements are perceived and can be articulated by frontline staff.

This type of engagement represents a move away from detached analysis and toward a deeper understanding of on-the-ground realities. When leaders understand the daily challenges and victories employees face, they can make better-informed decisions and offer more effective support. This proximity to the value-creation process allows executives to see the impact of their decisions in real-time, increasing the likelihood of strategic alignment and operational effectiveness.

The Pitfalls of Over-Mechanization in Lean Practice

One of the key risks in deploying Lean tools and techniques, such as rounding or Gemba Walks, is the development of overly mechanical approaches where checklists and schedules are followed without grasping the true intent behind them. A Lean transformation can falter if it becomes an exercise in box-ticking rather than a genuine shift toward operational excellence.

To avoid the pitfalls of mechanization, it's critical to focus on the behaviors that reinforce Lean principles. Leaders should ask probing, non-judgmental questions and demonstrate genuine curiosity about processes and challenges. Simple directives often do not suffice; what is needed is a nuanced approach that encourages genuine inquiry and continuous learning.

Transforming Leadership Behaviors for Lean Success

Transforming long-standing leadership behaviors is daunting but necessary for Lean to take root. Leaders who have operated in traditional management paradigms for decades often find adjusting to Lean principles challenging. The change requires not just intellectual understanding but a fundamental shift in behaviors and actions.

When it comes to Gemba Walks, for example, it's crucial for executives to engage in learning and teaching, approaching the walks as opportunities to gain insights rather than solely to enforce compliance. Leadership development in Lean should include preparing leaders for these shifts, providing them with structured tools and processes that support this transition. By framing such activities as formative experiences with clear value propositions, executives can appreciate their impact on sustaining a culture of continuous improvement.

Leveraging Assessments in Lean Leadership

A structured approach to assessing Lean practices can be tremendously helpful in guiding leaders on their Lean journey. Standardized assessments with diagnostic questions and rating scales can be created to support leaders in evaluating specific elements, such as visual controls or standard accountability processes. This coaching tool can guide leaders to better understand and internalize what they should be looking for during Gemba Walks.

The assessment process helps translate the principles of Lean into actionable, observable behaviors for leaders. By pairing executives with seasoned Lean coaches, they can be guided through the nuances of the practice and understand the gap between their initial impressions and the reality on the floor. This method fosters a deeper level of understanding and commitment to continuous improvement.

The Role of the Executive in Advancing Lean Culture

Finally, it's essential to recognize the unique role that executives play in the perpetuation and deepening of Lean culture within an organization. Their responsibilities extend beyond merely model behaviors; they must actively diagnose areas for improvement and work cross-functionally to improve the integrity and effectiveness of Lean systems.

By participating in Gemba Walks and engaging with frontline teams, executives demonstrate their commitment to Lean principles and underscore the importance of everyone's role in achieving organizational success. Their deliberate involvement sets the tone for a culture that values learning, coaching, continuous improvement, and a relentless pursuit of excellence.

Evolving Lean Thinking with New Resources

The evolution of Lean thinking and its practices is greatly supplemented by fresh resources that provide insights into the implementation of Lean principles in modern contexts. The release of a new edition of a Lean-focused book marks an important milestone for practitioners seeking to update their knowledge and refine their operations. These resources often encapsulate the latest experiences, strategies, and reflections from thought leaders in the field, making them indispensable for organizations committed to continual improvement.

The Power of Multimedia in Lean Learning

Multimedia, including videos and audiobooks, has proven to be an effective medium for disseminating Lean knowledge. The use of videos to complement books allows readers to gain a more tangible understanding of Lean concepts by showing real-world applications and examples. Similarly, audiobooks cater to the busy lifestyles of professionals who can learn and absorb information while engaged in other activities like driving or exercising. This flexibility in learning adapts to the varied learning styles and preferences of individuals, thereby maximizing the reach and impact of Lean education.

Integrating Lean Content Across Platforms

To leverage the full potential of multimedia Lean resources, it is important to ensure that valuable content is readily accessible across various platforms. By embedding informative videos on websites and podcast episode pages, thought leaders in Lean can expand the touchpoints where interested audiences can engage with Lean content. This integration creates a seamless learning journey for those exploring Lean, enabling them to effortlessly move between reading material, listening to insightful podcasts, or watching educational videos.

Embracing Community Engagement in Lean Practices

The Lean community thrives on engagement and the sharing of knowledge. Individuals are encouraged to not only consume content but also to participate actively in discussions, be it through commenting on blog posts, emailing questions to podcast hosts, or attending web-based seminars. Such interactions foster a vibrant Lean culture that supports peer learning and the collective advancement of Lean methodologies. By actively engaging with content creators and fellow practitioners, community members contribute to a dynamic ecosystem that nurtures innovation and learning from one another's experiences.

Continuous Learning through Innovative Lean Resources

Organizations and individuals committed to Lean must cultivate an environment where continuous learning is a priority. Innovation in resource creation, such as the development of new book editions, podcasts, and audiobooks, provides the necessary fodder for this ongoing education. By utilizing these varied and modern resources, Lean practitioners can remain at the forefront of their field, continuously enhancing their skills, advancing their knowledge, and better preparing themselves to drive meaningful transformations within their organizations.

Placing a priority on such educational investments not only broadens the understanding of Lean concepts but also energizes a continuous cycle of improvement that resonates throughout the corporate culture. It is through the constant absorption of new ideas and perspectives that a Lean culture can truly flourish, maintaining its relevance and effectiveness in an ever-changing business landscape.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

Dr. Mann’s original thesis was the best way to change behaviors is to change the way we act. From the interview and listening between the lines, I think Dr. Mann no longer believes that and neither do I. Put in huddles, idea boards, visual controls, multi-level follow-up and leaders and staff will adopt a lean mentality. My own data point also says that this isn’t true or only true to a limited degree. Put in these lean tools or systems and five years later many leaders, including executives, are no more effective (dumber) than they were before they started. Dr. Mann says that executives can chase down the weak link by going out and rounding and asking the right questions. What if the weak link is the executive? Does anyone believe that the executive will self-identify that they just don’t get it or that they’ve failed to communicate what is important to their next level down?

Dr. Mann says that the lean folks should treat executives like customers. Maybe so, but in my own mind it is hard to believe that leaders at any level in Toyota consider themselves customers. I could make the argument that we treat executives too much like customers and by doing so we are doing Lean in places that are doomed to failure. In essence, we skip a vital step in order to get Lean underway, but by skipping this step we are limiting how successful the Lean implementation can be or are dooming the Lean transformation entirely.

I think the real problem in most Lean implementations is that the Lean transformation community ignores the necessity to bring the c-suite executives up to a certain level of personal mastery of some very basic (but not easy) Lean concepts before moving forward with implementation. Learn-as-you go doesn’t work well for the C-suite compared to learn-in-advance.

Karen Martin recently wrote that in a Lean leadership learning activity she lead, only 2 percent of the participants were readily able to identify the the problem for a situation that was posed. Really? Should we not question the competency of the other 98 percent of supposedly competent leadership? How can we effectively be leading Lean when such a basic skill such as problem identification is missing?

I do appreciate Dr. Mann identifying that there are clear differences between tactical and strategic lean leadership and his description of unit assessments. I am looking forward to applying this more specific approach.

I am also intrigued with Dr. Mann’s comments about how surprised he was with the many successful adaptations of Lean he has seen. I have seen too many “by the book” Lean transformations where indeed, leaders and implementers are just going through the checklist but not really fundamentally improving.

I should have two copies of Dr. Mann’s 3rd edition on my desk come Monday morning; one for me and one for my boss.

Thank you Mark for making this kind of stuff available.

I think we can’t expect to put in artifacts of Lean thinking, like boards, visual management, and expect the actual thinking to change. How often do idea boards become a way for leaders to blame or punish people for reporting problems? How often are the boards and ideas ignored?

I see one of the biggest glaring problems with Lean healthcare being that CEOs think it’s a program to implement and something that can be delegated without their involvement.

How many hospital CEOs have board members or advisors in the community that can challenge them to change their ways and behaviors? This happened for John Toussaint at ThedaCare and for Gary Kaplan at Virginia Mason.

I’m not surprised with Karen’s assessment. When I’ve done problem solving training in an organization, I’ve found that good problem solving skills are LESS likely there at higher levels of the organization. Why? People get promoted for being the ones to jump to solutions and to take action. There are often decades of bad habits in hospital senior leaders. This can’t change overnight. They often don’t want to change or don’t see the need to change.

Oh, and please report back what you think about the book and let us know if your boss actually reads it.

Mark/David,

Great podcast! I listened to this one while driving the kids from NC to TN to visit family during the holidays and thoroughly enjoyed the discussion.

I especially liked the emphasis on answering the “What’s in it for me?” It definitely prompts the lean leader to give pause and examine their approach.