We just finished our second day of our Kaizen Institute Japan Lean Tour and it's been great so far. Follow us via the hashtag #KaizenTour on Twitter for more real-time updates.

Monday afternoon, we visited Toyota's Tsutsumi plant in Toyota City, where they produce Prius and Camry models. In the theme of being an “eco-factory” for eco-cars, they have solar panels on the roof that generate HALF of the electricity needed to run the assembly line. Pretty cool.

We had an excellent English-speaking tour guide for our visit (she lived in Hawaii at one point). As we talked through the facility (up in a “catwalk” that gave good visibility down into the process), she would occasionally stop at pre-determined points to explain something about the process or about the Toyota Production System and its elements.

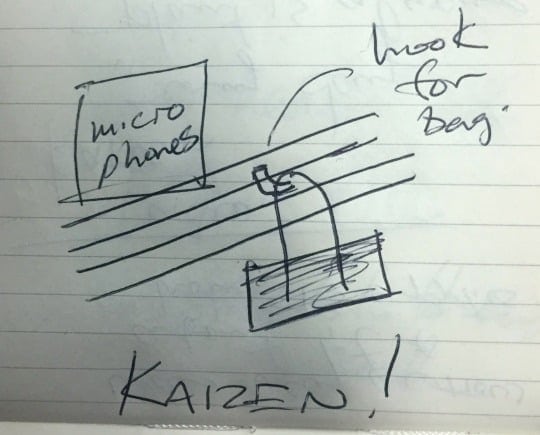

At each stop, there was a box with a microphone and other audio/visual equipment and speakers. She didn't have to carry a microphone with her.

The guide was carrying a bag, something between a briefcase and a large purse.

One of our sharp-eyed tour attendees, a Chief Medical Officer from a Canadian hospital, noticed a hook that she would hang her bag on while stopped and talking. He asked her about the hook.

Sure enough, it was a Kaizen improvement! And, it was her idea.

As she explained, she used to have to set her bag down on the catwalk, which she didn't like.

She had the idea of putting up hooks, an inexpensive change.

Here's my awful sketch:

When a Toyota employee has an idea, she explained, they bring up the idea to their manager. Sometimes, they first implement the idea and then write it up and share it with the manager.

The write up has the current condition and what you think should be changed (sometimes with pictures being added). In this case, she wrote it up and proposed it to her manager in public relations.

She said, “My manager normally approves things for me.” I asked her if all managers were like that and she said that some managers were “more strict” and didn't like to approve as many ideas, which is an interesting example of variation within their company culture.

The guide said that the managers generally encourage you to implement your own idea. I asked if she did that in this case and she said that a colleague actually attached the hooks for her.

I asked how they get new employees involved and she simply said, “The Kaizen idea suggestion system is explained to new employees and they do it.”

The numbers she shared were:

- 430,000 Kaizens implemented per year in Japan

- 68,000 employees total

- Thats 6.3 Kaizens per employee per year, on average

She has personally done two Kaizens in the past month (I didn't catch what the second one was).

Toyota pays 500 yen to the employee for each Kaizen idea, which is currently $4.36 in US dollars. They can be paid up to as much as 200,000 yen for special ideas ($1743).

I love seeing the Kaizen principles that I'd recognize and teach in healthcare:

- Set an expectation that employee ideas are welcome

- Approve most ideas

- Let people implement their ideas

- Write up a simple before and after explanation, with pictures

- Let people solve problems that matter to them

Russell Watkins asked a good question on Twitter:

I didn't ask why she needs the bag with her. Maybe a manager could ask that question in the course of Kaizen discussion, but they let her have her hooks.

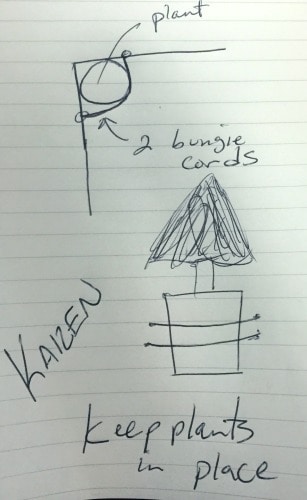

There was another Kaizen that she pointed out as we walked down a flight of stairs. They have small green plants in the corners of the stairwells. Somebody suggested adding two small white cords to hold the plants in place, as I've crudely sketched:

Clearly, Toyota is following the common Kaizen practice of not requiring some sort of Return On Investment (ROI) for each and every Kaizen.

It's more important to encourage participation, building capabilities and enthusiasm in employees. If they keep participating, some of their Kaizens will eventually save money for the organization. If we reject simple Kaizens “because there's no ROI,” then we lose that potential for future Kaizens that might have a more direct impact on different measures that matter to the organization.

Anyway, there is a little glimpse into life and Kaizen at a Toyota plant.

We're now going to be visiting three different hospitals in three different cities Wednesday, Thursday, and Friday, including one that I visited two years ago (see my post about the CEO and his comments on Kaizen).

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s build a culture of continuous improvement and psychological safety—together. If you're a leader aiming for lasting change (not just more projects), I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s talk.

Join me for a Lean Healthcare Accelerator Trip to Japan! Learn More

Kaizen as continuous improvement is great, but in the aspect of complexity do struggle many companies, including Japanese ones in setup of harmonized environment on a scale of GSC or supply chain. For many sites and factories small steps are being prefered and favouritized in favour to significant ones which can have much stronger impact on the Efficiency of the whole picture. This is what I see as weak point.

Perhaps it’s a definition of value in this context? The tour guide’s job is to guide people through the plant and impress upon them the sophistication of Toyota’s techniques, including kaizen. The hook is a very visible and tangible sign of the pervasiveness of kaizen at Toyota… or am I crediting the good and inscrutable sages at Toyota with too much cunning?

I’m certain it was only talked about because one of our attendees noticed the hook and asked about it, with me asking follow up questions.

Truely Impressed by the approach of doing and encouraging all the Kaizen having no or little impact on company s goal. When we started this approach we had a serious issue of quality of Kaizens. People just started to do use less Kaizens and wanted them to be included in the Celebrations. So our system of celebration was over burdened.

Like I commented below, if you’re just starting a Kaizen program and you’re starting to build a culture of continuous improvement, the quality of the Kaizens is not very important. The quality of the Kaizens will get better over time as you coach and develop people.

If the “system of celebration is over burdened,” is the system of celebration too complicated?

My co-author, Joe Swartz’s hospital has 4000 to 5000 Kaizens a year and their recognition system, with just 1 or 2 staff spending part of their time on it, doesn’t get overwhelmed.

In the workplace, shouldn’t the Kaizen be focused only on improvements to productivity, less defects, accuracy of info and so on ? Fixing a plant holder is about as helpful as recommending that someone fold the toilet paper in the washroom to give the appearance of a fancy hotel.

No. The Kaizen philosophy says that every small improvement is worthwhile. Why? Because at the very least it builds enthusiasm and confidence in the employee who had the idea.

If managers say “no” to ideas that don’t have a specific measurable benefit, then employees will often get discouraged and stop participating. Then, we lose the potential opportunity that their next Kaizen idea WILL more directly improve quality, or cost, etc.

Maybe the plant holder is a safety improvement, in that it reduces the risk that the plant gets knocked over and trips somebody on the stairs?

When we start with Kaizen, it’s especially important to say “yes” to as many Kaizen ideas as possible. This is taught by Masaaki Imai in his book “KAIZEN”and that has proven to be good advice in my own experience. You can’t mandate some sort of ROI threshold for each Kaizen, because again, you’re trying to build confidence and enthusiasm.

In data I’ve seen from my co-author’s organization and others, about 1 in 10 healthcare Kaizen examples has any sort of cost savings. About 1 in 250 or 300 has a really LARGE cost savings. If we don’t let people implement other Kaizens (especially inexpensive ones like bag hooks or plant holders) then we risk alienating an employee… and what’s the cost of that?

Mark

[…] guide (read about her Kaizen in this previous blog post), also explained that TPS […]

[…] Our Toyota Tour Guide’s Kaizen […]

[…] Source: Our Toyota Tour Guide’s Small Improvement — Kaizen in Action – Lean Blog […]

Comments are closed.