Mark's note: Today's post is a guest post by my friend and colleague Isaac Mitchell. We've crossed paths at conferences, including the annual Society for Health Systems conference, where he shared some of their great work on Kaizen that's being done at East Tennessee Children's Hospital. Hopefully we'll see you there in February with keynote speaker Kim Barnas (hear my podcast with her) and others.

How many of us have heard the phrase “but we don't have the time or money to solve problems?” Here's the deal: employees in organizations encounter problems every day. Your employees are spending time “solving” these problems to meet customer needs. Typically they are solving problems in the moment using workarounds that do nothing to prevent the problem from reoccurring. The next customer or next employee that is placed in a similar situation will encounter the same problem over and over again.

How many of us have heard the phrase “but we don't have the time or money to solve problems?” Here's the deal: employees in organizations encounter problems every day. Your employees are spending time “solving” these problems to meet customer needs. Typically they are solving problems in the moment using workarounds that do nothing to prevent the problem from reoccurring. The next customer or next employee that is placed in a similar situation will encounter the same problem over and over again.

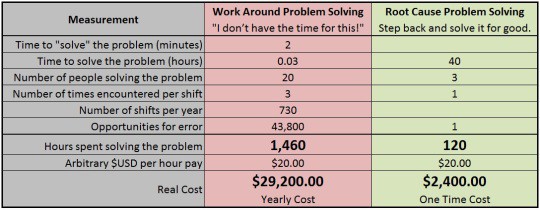

The question is not “Do we have the time to solve problems?” The question we should ask as leaders is “How can we develop people to solve problems to get to the root cause and solve them for future customers and employees?” If the concern of this is the time and money it takes to solve problems, then let's look at that the numbers and a comparison, below (click it for a larger view):

Why?

If we continue to operate believing that we don't have the time and the money for problem solving, we will continue to get staff merely working around issues. For example, to create a workaround, it takes two minutes for each employee. There are 20 people in the department working 730 shifts a year to work around the issue. That's 43,800 chances for an error to occur. The organization has invested 1,460 hours and $29,200 working around the problem and they will continue to do so.

Now, look at the right hand side of the table, where a company invests its time in root cause problem solving using the talents of their employees. The problem is identified and a team of content experts, which includes front-line staff, are assembled to begin root cause problem solving. Root cause problem solving involves using the scientific method to determine the source of the problem and then focuses efforts creating a countermeasure to prevent the problem from reoccurring. In this example, the team of three spends an entire week (120 labor hours) solving the problem at a cost of $2,400. The opportunity for this type of error to reoccur is reduced to one chance. The math is simple but powerful. Investing in root cause problem solving will save time and money while improving quality and decreasing opportunities for error.

How?

First, you have to have an organization that is committed to developing people for the capacity for problem solving. This includes providing time and resources to support this culture. The hard truth is that many of us in Lean continuous improvement roles have little influence over this commitment. We can show the numbers and provide support but ultimately it has to come from top leadership to set the expectation and then cascade it throughout the organization. From there, we can help support and expand this problem solving capacity.

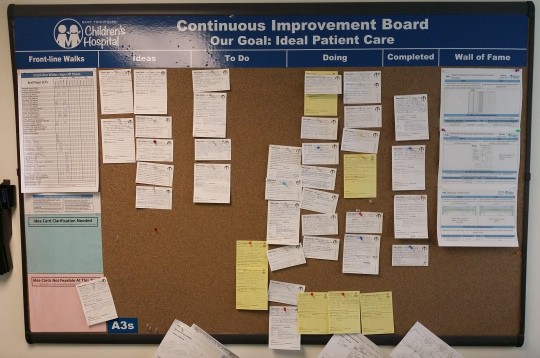

In order to accomplish this, you need to develop a methodology and process for improvement. There are several different approaches for this but what I have found most beneficial is department based idea boards. Throughout the week, employees write their ideas for improvement and place them on the idea board. Employees, problem solving coaches, and leadership throughout the organization meet weekly for 15 minutes around their unit based boards. The stand-up meeting consists of discussing employee ideas, gaining agreement on the issues, providing project updates, addressing current barriers to improvement, and celebrating project completions.

See an example of a board below:

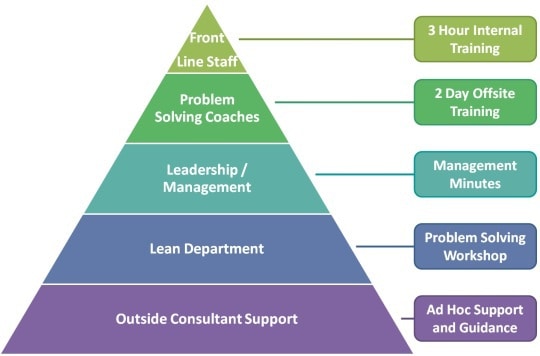

Finally, you must develop a support system to help employees in the problem solving process. Several levels of support are needed to create the culture of daily problem solving.

It starts with every employee understanding the expectation and basic knowledge of root cause problem solving. To support staff, develop problem solving coaches that are unit based. They spend an extended amount of time learning tools such as direct observation, value stream mapping, and A3 problem solving (PDCA) to support root cause problem solving.

The next level of support is for the leadership and management to help coach staff and provide time for problem solving. The lean department supports all of the efforts through developing people to further extend their problem solving capacity through workshops. These workshops focus on learning by doing with staff that needs additional support getting to the root cause.

Finally, the Lean department is supported through outside consulting and continuing education.

Summary:

Building the capacity for people to solve problem will reduce cost and improve your organization's quality. Leaders and continuous improvement professional must build a process that enables staff to participate in this culture. Additionally, you need to provide the time and resources for these efforts. As a result, you will develop an engaged workforce that finds joy in their work of fulfilling customer needs. Remember, your organization is solving problems. What type of problem solving organization do you want to be?

Challenge Questions:

- How are you as a leader building the environment to promote root cause problem solving?

- How are you as a leader or continuous improvement professional developing people for the capacity to problem solve?

- How are you as a continuous improvement professional supporting staff in root cause problem solving?

- How are you as a leader creating time for front-line staff to problem solve?

Bio:

Isaac Mitchell has over ten years experience driving change and improvements utilizing lean methodology in industries ranging from automotive to small machining job shops to healthcare organizations. He is a full time lean practitioner at East Tennessee Children's Hospital and lecturer at the University of Tennessee's Department of Industrial and Systems Engineering. Isaac's passion and focus is on training and implementing lean techniques to transform work cultures that improve healthcare processes and outcomes for patients and providers. For more information on his background please visit www.isaacbmitchell.com.

Isaac Mitchell has over ten years experience driving change and improvements utilizing lean methodology in industries ranging from automotive to small machining job shops to healthcare organizations. He is a full time lean practitioner at East Tennessee Children's Hospital and lecturer at the University of Tennessee's Department of Industrial and Systems Engineering. Isaac's passion and focus is on training and implementing lean techniques to transform work cultures that improve healthcare processes and outcomes for patients and providers. For more information on his background please visit www.isaacbmitchell.com.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

I like the idea of skilled unit based coaches assisting with root cause analysis. Many problems need a disciplined approach and applying RCA certainly is taking problem solving to the next level compared to quick fixes without RCA. I am curious why in the graphic that management only gets minutes of training on RCA. I may be misinterpreting the graphic, but it seems to me that disciplined problem solving would be a management fundamental.

Great question and point of clarification needed on my part. Unit based management along with related hospital directors and administrators complete the two day offsite problem solving coach training as well. However, the ratio of front-line staff to management in the training is roughly 4 to 1 to help with front-line ownership of ideas.

The Lean management minute is tailored specifically for leaders to address a wide variety of topics. They receive a brief overview and education of the topic and are then asked to experiment in their unit over the next month. For example, topics over the last two months have included effective pre/post data collection to measure project results and coaching front-line staff in problem solving using humble inquiry.

This was a great post! I hear “We don’t have time to solve problems” all the time. Leadership support and patience is definitely crucial to work through that.

I’m curious about how you deployed the unit-based problem solving coaches. Was it an all at once thing or did you start with a few units and then spread out?

We rolled it out department by department over the past three years. We started out with one pilot unit to experiment and learn what worked for our organizational culture. From there, we expanded it by 2 to 3 departments every three months. We came up with this timing based on our ability as a Lean department to be able to support the unit until they were self sustaining the process and methodology. Representatives from the Lean department still attend continuous improvement board meetings in all areas to help guide and support the efforts but each department runs their board independently.

Interesting post and an excellent graphic to speak to the importance of root cause analysis. Could you please provide the source for the table/graphic? Thanks.

These are all graphics that I created. Please feel free to use and share.

Great post! Certainly problems have varying levels of complexity. How does your approach educate your employees on which problems need proactive, thoughtful solving and which problems are easily blown out of proportion by such attention?

Problem solving and decision making can sometime be at odds.

Thanks!

[…] On the LeanBlog.org site, Isaac Mitchell tackles the issue of whether ‘workaround’ fixes are actually worth the effort, or if getting to real root cause is a better investment. It’s a topic that’s been around forever. The recommendations aren’t surprising. Check them out HERE. […]