California week on the blog continues after yesterday's post about Lean at San Francisco General Hospital.

Today, I'm flying to Los Angeles to attend the 5th annual Lean Healthcare Transformation Summit. I will be, as usual, moderating the CEO panel and I will be, for the first time, moderating the Q&A session at the end of each keynote talk. Follow along on Twitter with hashtag #HCsummit14 and I'll be blogging about things over these two days.

Speaking of California (and the LA area), I was pointed to this new YouTube video that was produced by Harbor – UCLA Medical Center and their eye clinic. In the video, healthcare professionals and leaders talk about how Toyota (their TSSC group) helped them improve their operations and patient care. I'm assuming this work was done pro bono, as similar Toyota work has been done in the past.

https://www.youtube.com/watch?v=MSmnAGAGPO8&feature=youtu.be

I posted this video yesterday as a comment in reply to somebody who complained (rightfully so, I think) about top-down “Lean” that she's uncomfortable with. Lean isn't about the boss forcing people to make changes. It's a far more collaborative process and the Toyota/UCLA video shows this perfectly.

Some key aspects of the story in the video, to me, include:

Start with problems — it doesn't seem like the goal was to “implement TPS,” but rather to solve meaningful problems, such as the need to free up staff time (reducing frustration and wasted motion) and to increase throughput (to reduce waiting time for patients). Those are challenges that everybody can rally around. Notice there was no talk of cost cutting and CERTAINLY no talk about any need to reduce headcount. Not surprisingly, they found that residents spent more time in the hallways, looking for supplies, forms, etc., than they did actually being with patients.

Learning from another industry — Toyota did teaching onsite, but also brought hospital clinic staff to their parts distribution center to see what good processes look like. Good management practices certainly can be transferred across industries. Sometimes you need to “see what good looks like” if you're going to make major improvements (and “good” might be a hospital like ThedaCare or some factory in your community… as Toyota demonstrates here in San Antonio).

Gemba, observation, and mapping — Staff and leaders went to the “gemba” (the shop floor) to see how things really worked, observing and documenting (mapping) processes to learn what needed to be improved (how to identify and reduce waste, including rework). This includes learning to look at the bigger picture and broader systems, fixing flow, and reducing bottlenecks.

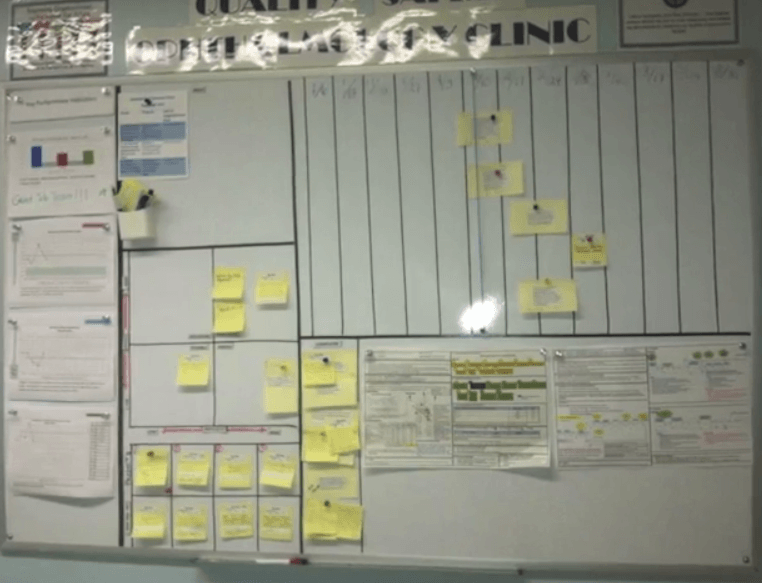

Kaizen — They introduced a board that the team huddles around once a week to identify and discuss ongoing improvements that can be worked on over time. This wasn't meant to be a one-time exercise and, again, certainly not a top-down process. They are now “constantly” looking for better ways to do things and they are tracking their performance.

Pride in their improvement work — You can tell the doctors, nurses, and others take pride in their involvement in the improvement process. The video is a bit staged, of course, but people seem to take pride in labeling themselves as “problem solvers” – they're making things better! “It's completely changed the way we work here,” says one resident.

The results include:

- Reducing the patient's clinic length of stay by 50%

- Increasing the number of new patients seen each day from 5 to 11 (which reduces waiting time and improves quality and outcomes)

- Staff are more likely to go home on time

- Starting to change the culture and the way they approach their work and improving their work, and staff morale has improved

Thanks to Toyota for their work and helping share this video! As a woman says at the end of the video, “If we can do this, you can do this!”

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s build a culture of continuous improvement and psychological safety—together. If you're a leader aiming for lasting change (not just more projects), I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s talk.

Join me for a Lean Healthcare Accelerator Trip to Japan! Learn More

Mark,

Do you have an updated link to this video? I was very interested in watching it but the link no longer works and I couldn’t find it by doing a general web search. Thanks.

Thanks for “pulling the andon cord,” James. I managed to find the video and I updated the embedded video in the post.

Comments are closed.