I sometimes torture myself by watching webinars given about “Lean Sigma.” I hear a lot of claptrap about Lean… things that are just demonstrably wrong. These aren't differences of opinion. These are statements that are factually incorrect and can be proven as such.

If you ever hear somebody say some variation of this phrase:

“Lean is all about efficiency”

or

“Lean is only about increasing speed and reducing cost”

Then please just stop the video or run, don't walk, out of the room via the nearest exit, to avoid being further misinformed by the speaker.

Normally, I would say “safety first” and mean it, but this case might be an exception.

Run away!

There's a dangerously incorrect notion that is accepted as gospel truth in Lean Sigma books… that incorrect construct says that:

- Lean is for speed and efficiency

- Six Sigma is for quality

Again, that's false.

The truth is Lean and Six Sigma both can (and should) accomplish both goals at the same time. Lean and Six Sigma can work together, but to say “you need Six Sigma for quality” (as I often hear) is incorrect. Toyota's factories don't “do Six Sigma,” as I've been told by Toyota people at the plant here in San Antonio. They teach everybody how to use basic statistical tools, but they don't train “belts.”

Lean is about both quality and flow. Speed and quality. And safety, cost and morale.

I asked my NUMMI-trained plant manager back in 1996 which thing our plant had to fix first – quality or productivity.

He wisely said “Both. They go hand in hand.”

Lean and the Toyota Production System are focused on:

- Flow (just in time)

- Quality at the source (jiodka)

You can read about this directly from Toyota and their corporate website. Please read that.

Whenever you hear somebody say or imply that Lean would somehow promote to inadvertently lead to “making bad stuff faster,” you should point them to that Toyota page. Oh, and run away.

This speaker said:

“Go ahead and use Lean on that quality problem…

…you'll speed up your quality problem and make bad stuff faster.”

When people say outrageous things like that, the record has to be corrected.

Why would Toyota or any organization that practices Lean want to “make bad stuff faster?” That's ridiculous and it would only be said by people who don't understand Lean.

Where does this notion come from? It's right on the cover of the seminal book on “Lean Six Sigma (2002)”:

There you have it, “Six Sigma Quality and Lean Speed.” It's hogwash. If people are just repeating what they've been taught, I guess we can't blame them.

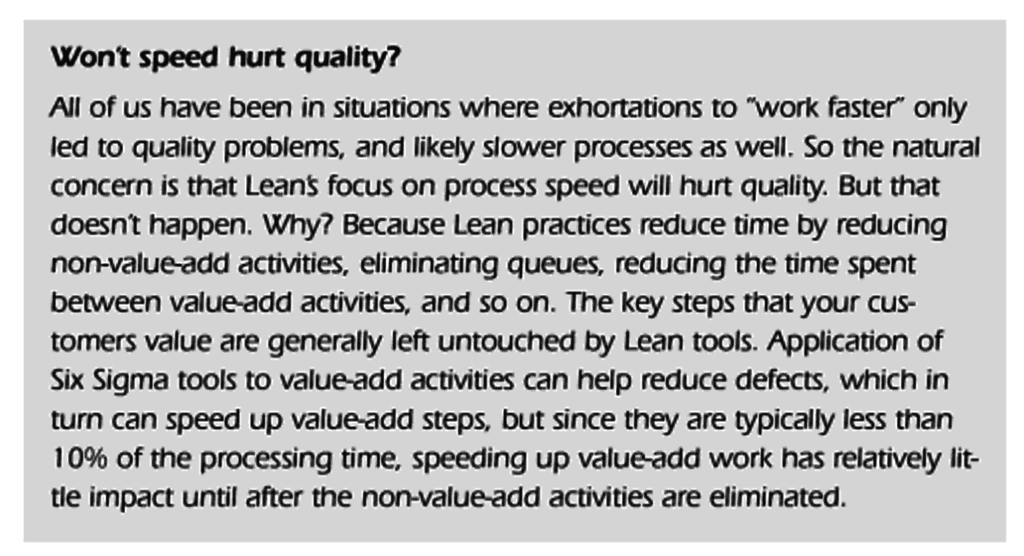

Then again, Mike George directly wrote that Lean isn't about making bad stuff faster:

Run away!

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

Exactly. I would add that attempts to combine both great concepts do a disservice to both. I have yet to see a “lean six sigma” program that isn’t a subset of lean and a subset of six sigma, where the subset of lean leaves out the critical “respect for people” aspect. Pretty much every lean transformation failure I’ve come across has failed due to not understanding and leveraging respect for people.

One should also run screaming when the discussion inevitably turns to “Lean and Six Sigma are just tools in the toolbox, so you use what’s appropriate for the problem at hand.”

That shows a gross misunderstanding of Lean, as well.

That’s why I’ve blogged before that calling the combination “5S Sigma” might be more accurate.

Thanks for the comment, Kevin.

Lean and TPS are focused on flow and quality at the source. This is true in manufacturing. Does this hold for healthcare also? Quality at the source certainly should. What about flow? Does safety supplant flow in healthcare?

I think it maps well to healthcare. Patient safety, not harming or killing them, is a subset of quality the source (doing things right the first time through good systems and culture).

Flow leads to better outcomes, as well… fewer delays before treatment means better outcomes.

These go hand in hand.

“Patient safety, not harming or killing them, is a subset of quality the source (doing things right the first time through good systems and culture).

Flow leads to better outcomes, as well… fewer delays before treatment means better outcomes.”

The US Veterans Administration would do well to pay attention here . . .

Right. I’m going to blog about that for tomorrow, I think.

The VA has had HUGE increases in demand for outpatient visits (doubling since 2002).

They aren’t meeting demand. They don’t have good flow. Could be poor processes or perhaps a lack of resources if they don’t have 2x the resources compared to 2002.

The VA leadership has pressured people to “meet targets” which leads to cheating when they can’t actually deliver those actual results the right wait.

It’s shameful… but I blame VA leadership instead of blaming the people who cheated and created “secret waiting lists” and the like.

Leadership created that system.

Mark,

Completely agree! When I hear so called “experts” talk about this I’ve tried to use it as an opportunity to teach and educate them on what Lean is really about. Usually through a private exchange – but maybe someone needs to stand up at one of these presentations and say “You’re Wrong!” – that would sure be interesting…

When I’ve challenged people directly on this, the response is usually either:

1) Well, you have your opinion and I have mine

I think that’s specious, because what they’re saying about Lean is demonstrably incorrect

2) This is what I was taught by an expert, a published author, etc., so therefore it’s correct

It might “correct” in the context of the common “Lean Sigma” body of knowledge as often taught (and so often repeated), but that repetition doesn’t make it any more correct.

Unfortunately, you’re right on, Mark. George Group et. al, now Accenture, is still spreading this notion. I hear it and fight it at work all the time in my role in “Lean Six Sigma.”

To me, Lean is a culture/philosophy. Six Sigma is a problem solving methodology. You can dip your toe in using Six Sigma. You sure as heck can’t dip your toe in becoming Lean.

Don’t even get me started on LEAN (all caps) – I want to find this person and make them pay.

See my blog post about LEAN in all caps.

Some have blamed the Lean Enterprise Institute for spelling it as LEAN at one point, but that’s not how they do it today.

I’d rather have LEAN and a proper understanding that Lean is about flow AND quality rather than Lean and the incorrect Lean Sigma definitions.

What was that, Samurai Warrior?

http://www.leanmemes.com/2013/09/samurai-lean-sigma-consultant.html

BTW, I love how Jim Bowie has Samurai Warrior from SNL in one of his presentations here:

http://www.lsssamurai.com/

I really like what Jason Stokes wrote above: “To me, Lean is a culture/philosophy. Six Sigma is a problem solving methodology. You can dip your toe in using Six Sigma. You sure as heck can’t dip your toe in becoming Lean.” Awesome.

@lean_productd on Twitter pointed out a book on “Lean Strategies for Product Development” (2004) that gets it wrong too:

Too funny. Had a “Lean Six Sigma Black Belt” from a major lab vendor do a presentation offering to do a workflow analysis for our lab. Only mentioned waste one time and not until deep into the presentation. Had to laugh. Love the Holy Grail clip!!!

What was the Black Belt there to do, convince you to buy new instruments? :-)

Some mistakenly say things like “Lean is all about waste” (it’s also about customer value, etc.) but it’s rare for a Lean or Lean Sigma discussion NOT include a lot of talk about waste.

There’s a Lean Six Sigma book for healthcare that says, incorrectly, that Lean addresses 7 of the 8 types of waste, but Six Sigma is used to address the waste of defects. That’s just insanely incorrect.

Mark,

You know he was trying to sell equipment! That said, I’ll probably let them do some grunt work for me then wrench it from his hands. Never once mentioned doing a VSM. Suggested we do a process map though. Won’t hurt to have some fresh eyes in there.

I’d say that a Value Stream Map is the really high-level view of a lab process… starting with the test being ordered, going through the information systems, getting the specimen collected, the testing done, the information back to the ordering physician and patient, etc.

A process map would be the more detailed view of one part of the value stream.

They’re both helpful depending on what problem you’re trying to solve…

The “problem” is that they think they want to install automation. Agree about VSM. I’ve always felt that you need the VSM at the high levels the process maps of each step in the vsm. Think I will push them to better define their problem. Thanks!!

Right, and what they’re doing is pushing a solution and that solution is automation.

I’ve worked with many labs that were able to reduce turnaround times WITHOUT automation. There are many ways of solving that problem through Lean thinking: re-arranging workstations, cross-training, reducing batching, new standardized work etc.

There are many case studies from my old J&J colleagues about “Lean labs” and, in many cases, automation was taken OUT.

There was one lab I worked with where the turnaround times were SLOWER with the automation they had put in because it was done really badly (hematology was the furthest location on the automation line). It took 20+ minutes to get through the automation conveyors when a person could walk it in less than a minute. The best solution would have been moving hematology closer to the pre-analytical area and the tube station.

Thanks. I think I will make them step back and spend some more time defining the problem.

We fully agree! There is a lot of misunderstanding.

We saw not so long time ago a man doing the VSM on his PC never going on the shopfloor.

He was approaching the VSM with Define, Measure etc. etc.

Is not crazy?

1) I’d avoid using the phrase “that’s crazy” in matters like this…

2) A value stream map shouldn’t be created by an individual using paper or an individual using software. It should be a team-based activity, drawing on people from different functions and departments.

3) That said, I’m not sure why DMAIC would enter the VSM process unless the VSM was part of their DMAIC Six Sigma cycle…

Here’s another example of a book with a table with many problems as it tries to compare Lean and Six Sigma:

https://twitter.com/karinaarceo/status/468138258614874112

Lean should also be driven by top management.

Lean supports the target of perfection (aiming for zero defects, etc.).

Lean impacts all aspects of business processes…

Lean can be achieved without Six Sigma, by the way.

And the following page isn’t much more accurate:

https://twitter.com/karinaarceo/status/468144773727928320

In both photos, from the same book, many of the things attributed to Six Sigma could also be attributed to Lean.

Six Sigma is a learning organization, but Lean is not?

Six Sigma is about quality, but Lean is not?

Six Sigma is about preventing problems, but Lean is not?

Good grief, that’s so horribly inaccurate.

Thanks for the clarification Mark!

[…] You might also remember this video that I blogged about: […]

I added an addendum to the post… even Mike George wrote in “Lean Six Sigma for Service” that Lean doesn’t create bad stuff faster.