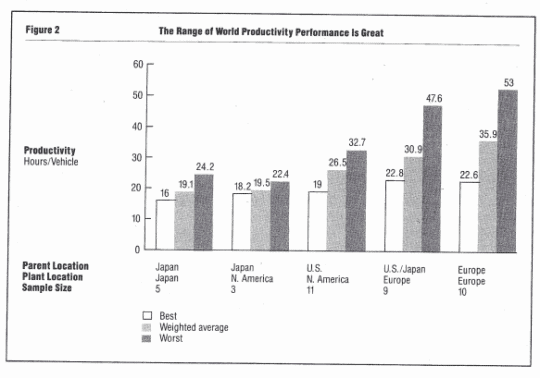

As discussed in the article that coined the word “Lean,” productivity was clearly better for the Japanese automakers:

Toyota was clearly doing more (output) with less (people) compared to GM, Ford, Chrysler, Mercedes, etc.

The Japanese also had better quality, faster time to market, etc. It wasn't just about efficiency.

Toyota was the definition of Lean, essentially, with their methods, philosophy, and management system.

So, Toyota (Lean) was doing more with less. That's true and it shouldn't be controversial.

So What's the Controversy?

If we were comparing one hospital against another… it might true to say ThedaCare provides more patient care per employee than the average hospital. I don't have the data in front of me, but ThedaCare has improved productivity by 25 or 30% in some areas.

It's very important to keep in mind that ThedaCare has a “no layoffs philosophy.” They are improving productivity, but they aren't firing people. They are probably reducing headcount responsibly through attrition and retirements. I know they are reassigning people to other areas, including their internal Lean group.

The reason people have concerns (or freak out) about the phrase “doing more with less” is that they hear it as “YOU'RE GOING TO LAY PEOPLE OFF!” Or they'll understandable get upset and say “YOU JUST WANT US TO WORK HARDER!”

I'd avoid using the phrases “we're going to do more with less” or “Lean is about doing more with less” in an internal Lean education or transformation effort. I think I rarely, if ever, use this phrase myself, even though it's true.

Like the word “Lean” itself, the phrase is too easily misinterpreted as something that we don't mean (or shouldn't mean) with Lean.

I have former clients of mine who are, for example, doing 30% more laboratory testing with the same headcount levels as they had in 2006 or 2007. They are “doing more with the same number of people” or “doing more with less.”

But, they haven't laid off people. They've sometimes been able to not replace people who quit or retire, but that's not harmful to morale like layoffs are. I should say it's not harmful to morale IF you have actually done process improvements that allow you to do “more with less.” They're not making people work harder. They've eliminated waste and frustrations that interfere with doing the work that matters.

You can't put the cart before the horse. Just firing people will NOT improve your productivity, anyway. You might be doing less (work) with less (people) or you're going to be doing the same amount of work, but quality or safety will suffer if people are forced into cutting corners. That's clearly not good and it's not Lean.

You can't force people to do more of what they're doing. You have to re-think processes, redesign your systems, and eliminate waste. That's what allows you to do more.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

![When Was the Last Time a Leader Around You Admitted They Were Wrong? [Poll]](https://www.leanblog.org/wp-content/uploads/2025/07/Lean-Blog-Post-Cover-Image-2025-07-01T212509.843-100x75.jpg)

Doing more with the same number of people is a good definition. It just doesn’t have that marketing cachet.

Somebody commented on Facebook:

Less Employees Are Needed might be very true when comparing two organizations. But, an organization on a Lean journey cannot use Lean to drive layoffs. That’s the point of my post.

Toyota needed fewer employees than GM. That was the finding of the Lean articles 25 years ago. Less Employees Are Needed. That’s a fact. But don’t use that phrase and don’t lay people off.

A good Lean hospital needs fewer employees in some areas than a normal hospital. But, that Lean hospital didn’t get there by laying people off.

It strikes me that how we get to “less” (whatever that may be) is just as important as the “less” itself: Did we “cut heads”? or did we make work easier so the job takes less effort?

I’ve heard Taichi Ohno quoted as asking “how could we do this job with fewer people?” Note that this is phrased as a question and that the question is “how?”. Very different from a directive that says “we are cutting your workforce/inventory/work area!”(whatever the “less” is that management is pursuing).

Lean is doing more and more and more with the same resources. It is about continuous growth in productivity over time without necessarily adding resource each time to get it.

But you’re right. It’s not a bumper sticker.

It’s not necessarily the “same” resources. If you need to and can reduce through attrition, that’s fine. Better though to use Lean and productivity improvement as a growth strategy when you can.

For hospitals Lean should translate to more time for clinicians to spend actually taking care of patients! With all the regulatory requirements it becomes increasingly apparent that we do less patient care and more NVA work – so Lean should take us back to what we need to do – heal the sick.

Amen. There is so much waste in healthcare, we can free up time for MORE patient care. That’s job one. But healthcare also ultimately has to have higher productivity without harming quality due to demographics. That is our challenge for the next decade or so.