When I recently did a Healthcare Kaizen workshop near Detroit, I invited an old friend of mine to attend as a guest. Marisa Smith, an entrepreneur and business owner in Ann Arbor, saw the connections between my Kaizen work and a book that she uses within her company and with her clients: Traction: Get a Grip on Your Business

When I recently did a Healthcare Kaizen workshop near Detroit, I invited an old friend of mine to attend as a guest. Marisa Smith, an entrepreneur and business owner in Ann Arbor, saw the connections between my Kaizen work and a book that she uses within her company and with her clients: Traction: Get a Grip on Your Business.

I read the intro and jumped right to Chapter 6 on “The Issues Component.” There's a lot that's very similar to Kaizen and Lean… but a few key differences. The author, Gino Wickman, says a company needs an “Entrepreneurial Operating System” that consists of key components:

- Vision (a compelling one that people are aligned to)

- People (great people; the right people in the right seats)

- Data (handful of key metrics to manage the business)

- Issues (identifying and fixing them)

- Process (a consistent and clear way of doing business)

- Traction (execution, focus, accountability, and discipline)

Wickman says that these are sequential… that you can't or shouldn't work on Issues if you don't first have Vision, People, and Data set up. Fair point and that sounds like good advice.

But, I wanted to see first what his approach to “Issues” was. I'll go back and read the rest of the book at some point.

Early in the book, on page 6, Wickman says that stopping to take the time to solve issues, saves you 2x to 10x the time. I see so many hospitals say they “don't have time for Kaizen,” yet they somehow have time to fight the same fires each and every day. I had a client recently where the E.R. director realized in the first two days of our Kaizen coaching that putting time into Kaizen, working with staff, was going to quickly become a net time saver because things could get fixed instead of “10 different people all complaining to me about something.”

Taking time to fix things is a good use of time. I wish more people would test that hypothesis.

“By solving issues now, you'll save time exponentially across departments by eliminating all future symptomatic issues.”

Wickman says we need an “open and honest” environment, which reminds of Toyota and the way people are encouraged to speak up and point out problems. Wickman also says, “it's normal to have issues,” which is certainly true in healthcare. As Toyota says, “No problems is a problem.” What's a problem is not working on those issues, I'd say. Wickman points out that being open and honest starts with leadership… that trust and emotional safety have to be there first. Leaders can set the tone by “openly admitting mistakes and issues” and “then working together to solve them.” Amen.

Wickman says that effective organizations “don't let [issues] linger for weeks, months, and years at a time.” We have to expose them and not “hope they go away on their own.”

He adds:

“Nobody has ever died from being open about issues.”

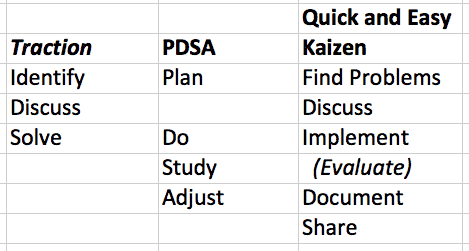

His high-level process is very similar to PDSA and Kaizen, as this table that I put together shows:

I appreciate that Wickman says the “Discuss” phase can't go on forever. I see a lot of hospitals that are trying to get out of the old habit of talking about problems over and over in monthly committee meetings that don't accomplish anything. We need to work to find the “root of an issue” (the root cause) and fix things.

He does have good advice that the Discuss phase should go on long enough so that “the issue is clear.” As they say, “A problem well defined is half solved.” It just can't get off on “tangents” on go on too long. Good advice.

I don't like that the Wickman process ends with “Solve.” The classic PDSA model realizes that “solving” a problem is really an experimental process (as opposed to a certain one). We test a countermeasure and study to see if it worked (and if there were any side effects)… and adjust accordingly. We might call it “solved” but it's likely just better than it was before.

Another thing that Wickman said that goes against the Lean and Kaizen approach is his statement:

“… cause of the real issues are people.”

No! A Lean thinker is “hard on the process, not the people” (see Sunday's Super Bowl coin toss). Dr. Deming taught that roughly 94% of the problems and defects in a company are caused by the system, not the individuals. Wickman says it can be awkward when one of a leader's staff members is responsible. Hmmm… that's blame. He then says “trust is so important” in the same paragraph, but blame and trust don't exactly go together like chocolate and peanut butter.

In one of his “John is responsible” examples, Wickman points out that John is not in a role that's a good fit for him. That's actually a system issue, I'd say.

Wickman recommends having three “Issues Lists”:

- Shelved issues – things that can be addressed more than 90 days out

- Weekly leadership team Issues List (more strategic stuff that must be solved by leaders (things like major client difficulties, bad numbers in the scorecard, etc.)… otherwise “if it can be solved at a departmental level, push it down.”

- Departmental Issues list (local level stuff).

When looking at the issues list, Wickman says to “decided on the top three issues to be solved,” which is the same question Toyota asked in that “no problems is a problem” story — what are your top three issues? He has 10 “commandments of solving issues” (with my comments in italics.

- Thou shalt not rule by consensus (a workplace is not a democracy and it's NOT the UN Security Council where one person gets a veto)

- Thou shalt not be a weenie, having strong will and firm resolve to make tough decisions

- Thou shalt be decisive (yes, but thou shalt be willing to adjust in the PDSA mode instead of being stubborn)

- Thou shalt not rely on secondhand information (just as Toyota preaches — go and see… observable facts over distant data)

- Thou shalt fight for the greater good (focus on the vision)

- Though shalt not try to solve them all (better to actually solve something than talk about solving everything)

- Though shalt live with it, end it, or change it (agree, no whining about issues)

- Thou shalt choose short-term pain and suffering (focus on the long term, as Toyota says)

- Thou shalt enter the danger – work on what you fear most

- Thou shalt take a shot – propose a solution (agree that the boss has to do this as a last resort and then listen to feedback from staff)

There's a lot of really good stuff here. The “Entrepreneurial Operating System” is a structure that Marisa says works well for her and her clients. I'm excited to read the rest of the book.

One thing Marisa pointed out, a fair point, is that Wickman is writing for a different audience (smaller companies and startups) where most of the Kaizen material (including my own) is targeted toward bigger organizations. It's interesting to think through how the process or the advice might vary based on those different audiences. What do you think?

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

![When Was the Last Time a Leader Around You Admitted They Were Wrong? [Poll]](https://www.leanblog.org/wp-content/uploads/2025/07/Lean-Blog-Post-Cover-Image-2025-07-01T212509.843-238x178.jpg)

Your comment about — It’s interesting to think through how the process or the advice might vary based on those different audiences. What do you think? My thought to this comment is that no matter the size of a company Kaizen, Dr. Deming’s, and EOS principles (except for the two differences you mentioned) are solid and work. I also agree with you about your solve comment — issues are usually improved on never completely fixed. Now I really liked your mentioning Dr. Deming and his take on what percent of problems are caused by people. I loved to hear Dr. Deming say that when he asked managers and executives what % of their problems were due to people and he said they would answer all of them and he would answer in his classic voice — WRONG. They are caused by the system. People are part of the system and management is responsible for the system. Tks for allowing me to comment.

Thanks for reading and thanks for commenting!

I agree these methods and mindsets are pretty solid and universal. Using slightly different frameworks or labels is fine by me.