In a new video released by the Lean Enterprise Institute, CEO John Shook talks about a “Lean transformation” model. He starts by explaining how “prescriptive implementation models” have been attractive to many organizations and “that can be effective in making a certain amount of improvement and learning” but there's a better approach than “copying” Toyota's tools and techniques.

In a new video released by the Lean Enterprise Institute, CEO John Shook talks about a “Lean transformation” model. He starts by explaining how “prescriptive implementation models” have been attractive to many organizations and “that can be effective in making a certain amount of improvement and learning” but there's a better approach than “copying” Toyota's tools and techniques.

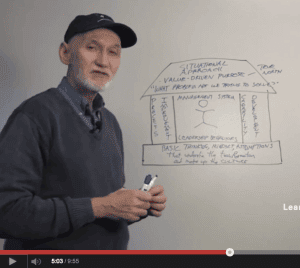

Here is the video:

In the roof of the house is the “situational approach” – as the situations faced by different organizations will be different. I'd add the example of one hospital that is short on cash and might be going bankrupt in a few months versus a second hospital that has financial stability and is looking to go from “good to great” on patient safety and quality.

Shook says we need a “value-driven purpose” or a “true north.” The simple question that leads to that is “what problem are we trying to solve?”

The first of the two pillars he draws is “process improvement” (changes to the work). He says “Lean is sometimes mistaken as a process improvement program when it's much more than that). The second pillar is “capability development” or “developing the people.” This reminds me of the two “equally important pillars” of the Toyota Way management system – “continuous improvement” and “respect for people.”

People are in the heart of the diagram, of course — the management system and the leadership behaviors. The foundation includes “basic thinking, mindsets, and assumptions.”

Shook says this model leads to a set of questions:

- What problem are we trying to solve? What is our true north?What value are we providing?

- How will we improve or change the value-creating work?

- How will we develop the people (at all levels of the organization?

- What leader behaviors and management systems are required to lead work in this new way we're transforming?

- What basic thinking, mindsets, and assumptions underlie or define the transformation?

I agree with Shook that too many organizations have focused on copying tools. The right tool in the wrong culture can be useless or harmful. Putting an “andon cord” up is a waste of time if it's on an assumably line where workers are afraid they will get yelled at for stopping the line (instead of being praised for putting quality first and receiving assistance in resolving the problem).

I had a chance to visit Livonia Public Schools last Thursday (the district I attended from first grade through high school graduation). Jeff Fuchs (also a Livonia product) has volunteered to help them and I'm impressed that they are focused on solving problems, as Shook described. I didn't see half-hearted attempts at “5s-ing” the headquarters supply room. Instead, I saw an approach where Fuchs was teaching them to solve problems that mattered (such as improving the new student registration process) and people are being developed in the process. I'll write more about this soon.

Shook concludes by saying an organization can then develop a management and leadership approach that meets the goals laid out by the true north and those questions. Are we going to travel, benchmark, and copy or have an approach that's scientific in it's nature?

I see hospitals being VERY willing to spend money to travel, see “best practices,” and attempt to bring them home (an attempt that often fails). I wish hospitals were also MORE willing to put in the work to figure things out themselves through PDSA and a model like Shook's. It's really interesting and fun to coach people through problem solving… more fun than just copying somebody. Do you think you learn more copying or figuring things out yourself?

I think we'll have better and more effective Lean transformations, as a result. What do you think?

(hat tip to the LEI's Lean Post site for sharing this)

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

Thanks for sharing Mark,

I wish I had this six years ago.

What do you think are examples of a management system that he describes. Is this huddles, idea boards, daily management, etc?

I think one of the key things about John’s video is that he not at any point prescribes Lean.

The “roof” is focused on defining the problem, adding value, and the situation. How the components within the roof are supported or achieved will vary on the “improvement” side.

Thanks for sharing!

I think he is prescribing Lean, or at least a Lean Transformational model, but you’re right that he doesn’t say things like “first you must value stream map, and then do 5S, blah blah blah.” Lean thinking… a framework that allows us to figure out what to do. Powerful stuff.

[…] Lean is not “mean.” Lean should be focused, as John Shook says, on solving problems that matter. […]

[…] See this video with John Shook talking about that question and an improvement model. […]

[…] to that realization for focused on the key question of “what problem are you solving?”(as John Shook advocates) or “how are you better serving the customers and employees?” instead of just blindly […]

[…] Shook, from LEI, articulates this well in discussion of the LEI “Lean Transformation Model” – first ask, “what problem are we trying to solve?” Toyota’s Taiichi […]

[…] See more about John and the LEI Lean Transformation Model. […]

[…] for why Lean won’t work, the key thing is to figure out how to apply Lean to your setting. What problems do you need to solve? Focus on that instead of “implementing […]

[…] “what matters most?” That’s a great question. It’s a variation of the John Shook / LEI question of “what problem are we trying to solve?” I’ve heard Toyota people talk about the questions we NEED to solve. What’s […]

Still love this framework and the video. Mark – thanks for sharing! I reference this framework commonly in my own work, with my team, my customers, and visitors – pretty much anyone who is interested in this stuff!

I take your point re: Hospitals. Am happy to say ours is one that is trying hard to figure it out through PDSA and this model. Thank you Mark, John, and LEI!