I had a chance to go back to the Toyota Motor Manufacturing Texas (TMMTX) plant in south San Antonio last week with a group of executive education students at Trinity University. I first visited the plant back in 2010 and I've been there three times while living here the last two years.

I love helping take students there, giving them some pre-tour education about Lean (such as, “it's not all about robots”) and helping prep them with good questions to ask about “Lean culture” that would be transferrable to their workplace…. including continuous improvement AND respect for people.

I love Toyota's openness and hospitality… and I see something new each time – including how they are (of course) not a perfect company. So, it's time to share some more notes (see previous posts).

What are some of the possible opportunities for improvement? Although their main business, obviously, is not giving tours, it would be great if the process was waste free.

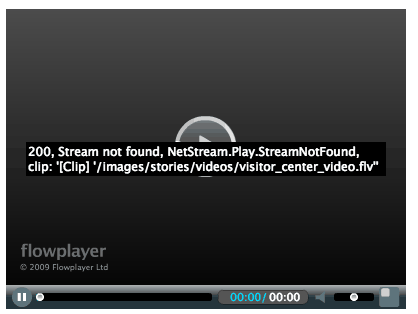

1) The plant tour website's video

The page on their website that promises a “tour preview” has a missing video file. If you view the page on an iOS device, you see a lot of blank space… that's due to the video player being flash-based. That's a different problem, but the one I'm talking about here is that , even on a web browser on a PC or Mac, the video player gives an error when you try to play the video:

2018 Update: This is still broken.

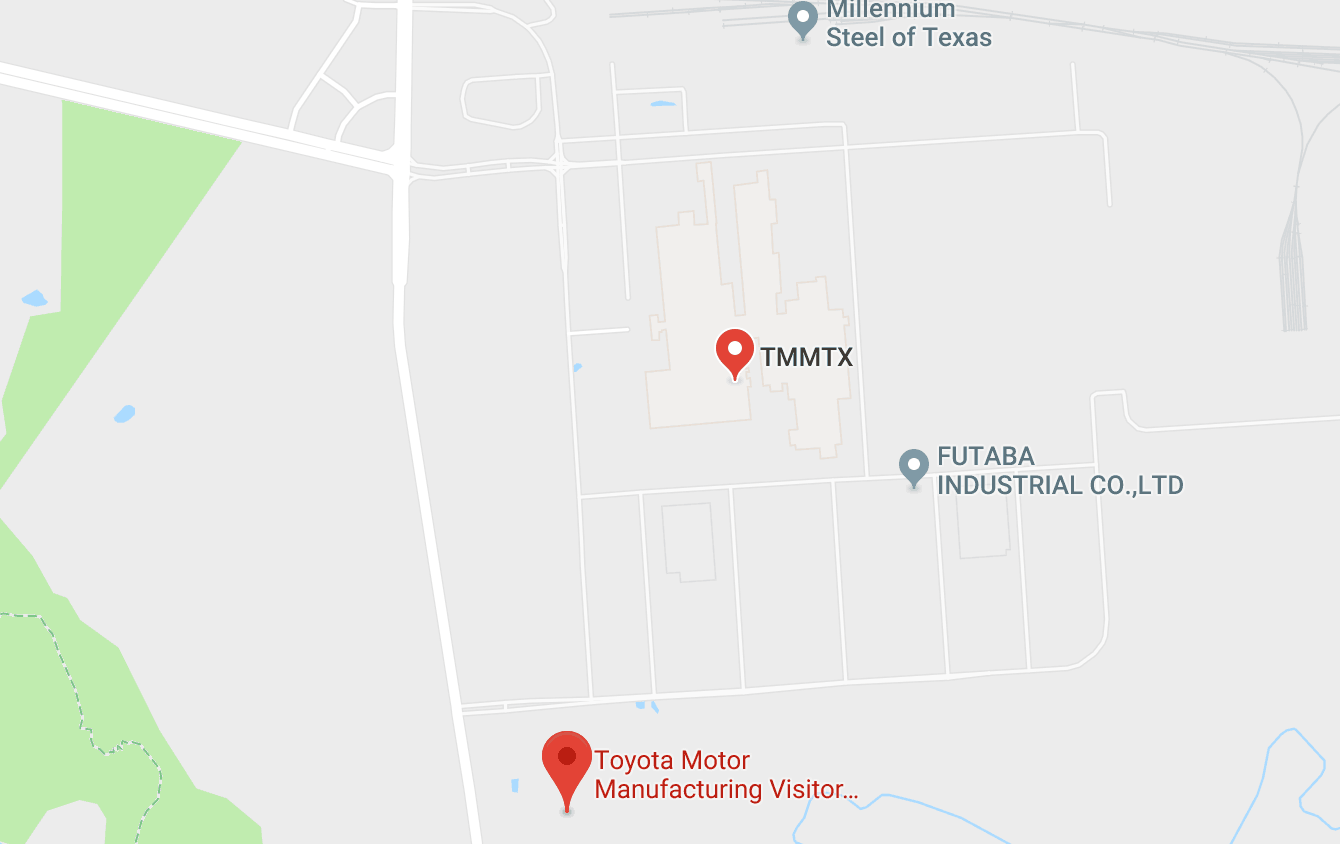

2) The website's directions to the plant could be better

The street address (and a Google Map) for the plant are on the website. The confirmation email for the tour says “Please visit www.toyotatexas.com.” But, it's pretty unclear how to find directions once you get to the site. You can look on the Tour page and it's not there. A map and an address are not “directions,” even in a GPS era, because…

2018 Update: Google Maps now more clearly shows the Visitor Center as a location. That's helpful.

3) Actually finding the tour start location is tough

The website lists the main address for the plant. As you get close to the plant (from downtown San Antonio), there's a road sign that says “<– Toyota Plant” to the left and there's even a sign (I'm pretty sure) that says “Toyota Tour.” So far, so good.

But, as you approach the plant (driving straight toward it), your GPS will want to take you to the main entrance based on their address. It's perhaps reasonable to assume that the visitor center is at the main entrance. Except that it's not there (a lesson I learned the first time I drove there myself). Security will tell you that you have to go back and turn south to head to the South Gate. There are three entrances to the plant (also a North Gate). Below is a view from Google Maps, including the sign that could be added to.

Inexpensive countermeasures for this would include A) adding to the “South Gate –>” sign so it also says “Plant Tour –>”. That would be less confusing for visitors. Another countermeasure (even cheaper) would be to put this information about the visitor entrance / tour start location in the confirmation email and on the website.

As of February 2016, there is no sign pointing to the visitor center. Maybe with the addition of the visitor center to Google Maps, it's not needed?

4) It's hard to hear visitor center announcements

After your time in the visitor center, there's a PA announcement made to get everybody to come to a room to watch a welcome video before moving on to the factory. When this PA announcement was made, everybody turned to each other to say, “What was that? Was that for us?” The speakers or the sound quality wasn't very good.

5) They ask you to be careful about the headset volume

When you actually get to the factory for the tour (after the visitor center introduction), you get a hard hat and safety glasses – safety first! You're instructed how to properly adjust the hard hat — and you're told “why” (a great Lean practice). You want the hard hat properly adjusted because you might look up at things and don't want it to fall off. They explain why you need to keep your limbs inside the tour tram (because material handling vehicles are coming by in the aisle).

You also get a wireless headset unit that you wear to be able to hear the tour guide as you go through. It's not that it's super loud, but you're on a tram and the guide is facing forward and you're behind them and wouldn't be able to hear.

They explain that the ear pieces are sanitized each time (thanks!). But, the guide warns you that, “When they clean them, sometimes the volume knobs get turned all the way up and you should adjust it down to make sure your ears don't hurt from it being too loud.”

So, it seems like they have a known problem. I'm surprised their countermeasure is telling the visitors to adjust the knob and to “be careful.”

It's good that they have standardized work to tell you this. But, it seems that the people doing the cleaning could make sure the knobs are set right. Or, this could be checked by the tour hosts before the tour.

The Good Things

Some of the interesting things I saw that are typical Toyota goodness. It seems like the Toyota culture to talk about problems first… and then the good stuff.

An introductory video says the die changeover times in their stamping area are “five minutes.” This certainly qualifies as “Single Minute Exchange of Die” (“single” meaning a single digit number, not one minute). When my wife and I toured a Range Rover factory in England last year, they said their die change time was 30 minutes. The equipment (progressive stamping with automation) looked very similar. Toyota stamps steel while Range Rover does aluminum. I don't know if the metal makes a difference or if the Toyota process is that much better?

The Lean/TPS education that's posted around the plant includes key concepts as “employee empowerment,” “continuous improvement,” and “training right from the first time.” I don't think these signs count as Deming-reviled “slogans” because I'm sure they mainly live by what's up there.

There's a lot said and written about Kaizen and continuous improvement. I think what's appreciated is the importance that Toyota places on TRAINING. I think that's part of the “respect for people” principle. It's unfair (and therefore disrespectful) to throw somebody into a job that they haven't been trained to do. You can see that Toyota takes training very seriously, as the tour takes you past the “training dojo” area where employees get to learn and practice key skills they need on the job.

Another interesting thing (on the topic of Dan Markovitz's recent post on the use of Japanese terms) is a room that is labeled, in a very Texas-y way:

“The KPI Corral”

While their visitor center highlights the use of Japanese terms (“Do you speak Toyota?,” see below) they have used American language for this room. Interesting.

The Japanese term for this room full of charts and “Key Performance Indicators” is “Obeya.” It's sometimes called a “War Room,” a term some people don't like (and I don't think is appropriate in healthcare).

I think their use of “KPI Corral” shows that it's OK (and maybe better?) to use English terms when we can…

Like I said, always an interesting tour. I appreciate very much that Toyota does these tours for free as a way to help educate the community.

It's also healthy to see that, for as much as Toyota gets put up on a pedestal, they are human and they're not perfect. I hope they're driven to improve some of these details about the tour as they are driven to improve things in their production process. I'm going to “pull the andon cord” and share some of my suggestions with the Toyota tour folks.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

Hi Mark, I also had de oportunity to visit the plant last July with classmates of my graduate program. We also got lost and we had to ask two times for the correct gate. I would add to your list that, although its not their purpose these kind of tours, if someone that speak spanish for a mexican group like us gives the tour would be a plus (or the lenguage of other groups). But I didn´t see how to give these kind of feedback to Toyota, what would be the best way? Box of suggestions?, web survey? Have you wrote something in your blog about this (the best way to receive suggestions? Greetings,

I’m surprised, given that this is San Antonio, that they don’t have the option for a Spanish-language tour.

It would be good if Toyota adopted a method that I’ve seen when visiting a “Lean” hospital in The Netherlands. When you walked through or did a tour, they gave you a card at the end where they asked you to write down what you liked and what you didn’t.

It seems that Toyota could do a better job of soliciting customer feedback at the end of the tours.

The website does NOT list an email address. But there’s an address on the tour confirmation form. I’ll send it to you via email if you’d like to write something to them directly.

Here in 2018, the “tour preview” video is still broken.

Currently, their registration page gives you a 500 error (and it’s been like this for a few days). It seems like they need some serious website help.

I pointed this out to the TMMTX tour email address and their reply suggests they don’t have a manual backup plan:

“Good Morning,

Unfortunately right now our reservation system is down so we are not able to check any availability or make any reservations right now. I do apologize.

Thank You”