They just started a year ago (better late than never?), but San Francisco General Hospital had its Lean efforts highlighted in the San Francisco Chronicle last week: “S.F. General following ‘Toyota Way' to efficiency.”

On the very same day, another headline flew past about a patient who had wandered off and gotten lost in the hospital (a so-called “never event“), with her body being found in a hospital stairwell: “Body Found at San Francisco General Hospital Is Missing Woman Lynne Spalding.”

The way the hospital reacts to this sad, unfortunate event might be a real test of whether they are adopting a true “Lean Culture” or if they are just running a bunch of “Kaizen Events.”

SF General has received grants to get help and training on Lean methods, as a way of getting more competitive in the challenging healthcare landscape:

“They're going to have to make themselves more attractive if they're going to compete for those patients who no longer have to go there because they have to,” said Dr. Mark Smith, chief executive officer of the California HealthCare Foundation, an Oakland philanthropy that has invested more than $2 million over the past five years to help hospitals adopt Toyota's techniques.

The foundation's grants have gone to a number of county health systems – San Francisco, San Mateo, Alameda, Contra Costa, Los Angeles – to help them re-engineer how they operate. That could mean everything from how supplies are organized to how many steps a nurse should take to reach essential equipment in the operating room.

San Mateo Medical Center's chief executive officer, Dr. Susan Ehrlich, described Toyota's method as “really focused on the small things. It's making a million small changes and making sure everyone is doing those changes and sticking to them over time.”

“A million small changes and sticking to them over time” — that's the essence of “Kaizen.” Lean isn't really anything exciting or glamorous — at the core, it's about the basic nuts and bolts of running and managing an organization on the daily basis — with customer focus, employee engagement, and a lot of focus and dedication. The SF Chronicle article defines Kaizen as being “continuous improvement,” but then to they refer to “a kaizen” as a week-long event. Kaizen is much more than week-long events (but that's why we wrote Healthcare Kaizen, to make that case).

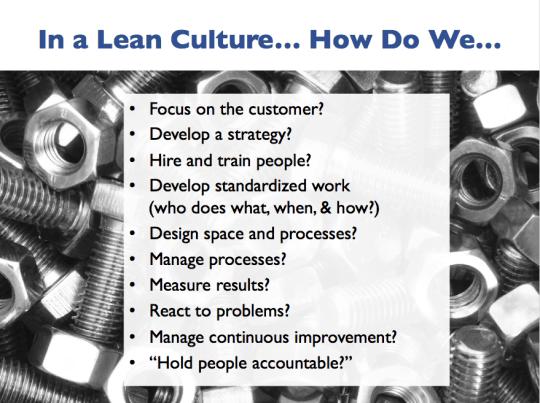

Here is a slide I've used in a few recent talks… about all of the “nuts and bolts” that are part of a Lean culture… “boring” operational details that make a big difference:

I put “hold people accountable” in quotes because its usual use in healthcare is a very loaded phrase… meaning, unfortunately, “how do we blame and punish people?”

A Lean culture has mutual accountability between leaders and employees. Leaders are accountable for creating a culture and a system that is conducive to safety, quality, and efficiency. Employes have an accountability to try their best, but best efforts aren't enough if there's a bad system or faulty processes.

The article talks about some of SF General's Lean improvements, which include:

- Taking “10 minutes off the hospital's average “wheels in” to incision time of 40 minutes.”

- Reducing urgent care length of stay from “4 to 6 hours” (that's not real precise) to 2.5 hours

San Mateo Medical Center has seen:

- Reduced surgical cancellations by 17 percent

- Saved $300,000 from February to August of this year by improving the process for getting insurance authorizations

Back to SF General and the sad story of their patient, Lynne Spalding.

A little more than two weeks after a 57-year-old patient disappeared San Francisco General Hospital, the county coroner confirmed late Wednesday that the body found in a stairwell this week was that of Lynne Spalding.

As you might expect, there are more questions than answers at this point:

Still, despite the announcement, questions swirled about how Spalding – a British native who worked in hospitality sales – could have ended up in a remote stairwell on the fourth floor. Spalding had entered the hospital on Sept. 19 with a urinary tract infection, and was last seen on Sept. 21. A friend said she had been feeling disoriented on her medication, but a doctor on Wednesday said her condition had been improving.

“We have no idea how this happened,” Chief Medical Examiner Dr. Todd May. “We are shaken to our core. What happened at the hospital is horrible. Our staff is devastated.”

A friend says:

“This is a nightmare,” Perry said. “Steps must be taken to make sure this never happens again.”

Exactly.

If SF General is really embracing a “Lean culture,” I hope they will focus on:

- Understanding HOW this occurred

- Identifying causes and root causes

- Putting countermeasures in place to 1) better prevent elopement and 2) have a better search process when a patient is reported missing

I hope the response does not include “naming, blaming, and shaming” an individual who was “at fault.” This seems like a very systemic error… with the organization (and its leaders) being responsible, not any one person.

It will be interesting to follow this case to see how SF General responds. This is a real test.

Virginia Mason Medical Center had a tragic patient death from a preventable medical error in 2004, very early in their Lean journey (the Mary McClinton case). While the radiology tech, Carl Dorsey, seemed to get thrown under the bus by many organizations, including the state. I'm sure he was devastated by what happened, especially since Dorsey had tried reporting the risk to supervisors weeks before the McClinton incident. I don't think any supervisors had their careers ruined there.

To their credit, Virginia Mason has become a much safer hospital, thanks in part to their “Patient Safety Alert” system.

ThedaCare, a few years into their Lean transformation, had a few “wrong site surgeries” in a short period of time, as they have written about in On the Mend. Hospital leadership stepped up to “stop the line” – not allowing any more surgeries until the cause of the problem was understood and countermeasures were put in place.

Now it's SF General's turn to, hopefully, set a good example by shifting from “name, blame, and shame” to real process improvement and prevention.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation: