Here's a fascinating article: “How Toyota brought its famed manufacturing method to India.”

The piece starts with a story about a classic Toyota management practice — “Genchi Genbutsu, or on-site inspection, which is at the core of the Toyota Production System (TPS). Nakagawa, who has been a TPS practitioner for four decades, doesn't believe in seeing things on his computer screen – he prefers to go where the action is. “Can a computer smell? Genchi Genbutsu is very important because only on-site will your sensory organs be alert – smell, sound, vision,” he says.

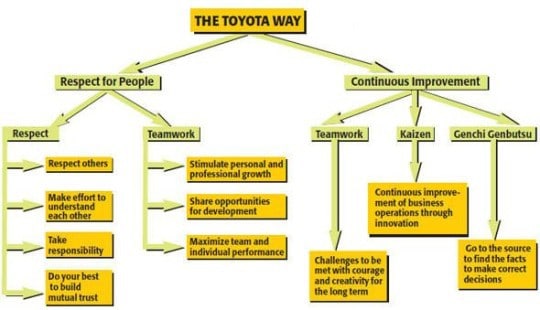

There's a great diagram that breaks down the two core pillars of The Toyota Way into more specific detail:

“Respect for People,” in particular, can be such a vague expression…

The diagram breaks it down into seven components:

- Respect others

- Make effort to understand each other

- Take responsibility

- Do your best to build mutual trust

- Stimulate personal and professional growth

- Share opportunities for development

- Maximize team and individual performance

I think this is further proof that “respect” in the Toyota framework is a active choice that we all should make – it's a choice in your daily behaviors and actions. You actively show and demonstrate respect for others, rather than it being just a vague notion in one's head. Edit: Arguably, as Bob Emiliani states so well in his comment (and in his books), respect for people is really an organizational requirement if you're going to have a truly Lean culture.

The article also talks about the connections between standardized work and kaizen:

While the process is continuously monitored to improve, the standard work ensures the process is checked and completed so that there is a continuous improvement toward the target. In other words, it is always a moving target with room for improvement.

Besides, there is much stress on PDCA, or Plan, Do, Check and Action, across the company. “A lot of companies are very good at planning but few can act and check on the plan, many can't even identify what went wrong with the plan and the action rarely takes place. Toyota processes tie down all aspects,” says Kirloskar, adding that weakest link in the chain when it comes to Indian companies is maintenance, which Toyota's PDCA executes rather deftly, as is evident from even top management visits to the gemba( place of work) to adhere to Genchi Genbutsu.

Be sure to check out all the pages of the article. It also touches on topics including:

- andon cords and the ability for workers to stop the line

- heijunka (level loading)

- A3 management

- just in time parts delivery (8 times per day)

- production being driven by demand

It's nice to see applications of these ideas consistently around the world.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

Historically, the “Respect for People” principle is not choice, but instead a necessary requirement to enable continuous improvement, in order to achieve flow. It is that RP enables CI, not the other way around.

A reason why RP is so often ignored is because leaders don’t know about flow or don’t care about achieving flow. That simply is not where they want to go. To them, CI (Fake Lean / L.A.M.E.) is plenty good enough. And, by doing that, they don’t have to bother with the hard work of changing and improving their beliefs, behaviors, and competencies (i.e. developing themselves).

Thanks, Bob. I didn’t state that very well, so I made a slight edit.

You’re right that it’s “required” — but what I meant is that it’s a daily active choice that we all make individually. Am I going to treat people with respect? If so, how do I demonstrate that?

There is one “thought leader” (and well-known bully) who said recently in a video to Jeff Liker that “respect for people is horse-sh*t” and that respect is an end-result of being effective at driving improvement.

He got RFP all twisted around and said basically that Taiichi Ohno was a jerk… but he got results… so he “was respected.”

Respect is something we offer to others… that’s where the bully gets it wrong.

Taiichi Ohno-San was not a jerk, but he did not accept excuses and he was tough. I should know because he was my sensei for 2 years before he passed. He always had respect for others, so therefore he was very well respected. I believe that many American Companies overlook this most critical aspect of doing lean. If they do not practice this fundamental, I walk away because I am not wasting my time, guess that makes me a jerk too then.

Thanks for your comment, Greg. No, that doesn’t make you a jerk. Respect for people means not accepting excuses and being tough – challenging people to do their best. Respect for people doesn’t mean being superficially nice or being easy on people.

Great example Mark. In regards to the Toyota Way, I have found that many people have a hard time seeing how all of the pieces work as a collective, integrated system. It is easier for many people to look at just an activity or event (reductionism). I would say that much of the reductionist thinking and behaviors originate from centuries of teaching and education (see Descartes). Many of these reductionist behaviors are still being taught and emulated. I have found that people typically do what they know. As a lean change agent, it is our duty to help illustrate the limitations of reductionism and open up the world of systems and emergent thinking. This duty can not be achieved without respect for people. Once eyes and minds are truly open, there is no other way to see the world around you. We all have blindspots including today’s leaders. Lastly, I believe that we must also show blind leaders respect.

In all summaries,TPS has two pillars, but never the same. Here, the pillars are “respect for people” and “continuous improvement.” To Ohno, they were Just-in-time (JIT) and Jidoka, with JIT covering production control, logistics, and supply chain management, while Jidoka was a complete approach to the engineering of production lines where humans interact with machines.

You could try to implement Ohno’s JIT and Jidoka without respect for people or continuous improvement, but it would not work well. Conversely, if all you focus on is respect for people and continuous improvement, you won’t get TPS either. You need both, and, perhaps, two pillars are not enough.

Broadly speaking, the two pillars in this article are about management; Ohno’s pillars, about technology. As TPS is based on the interplay of management and technology, perhaps these are its real “two pillars.”

Michel — The difference is:

TPS: JIT and Jidoka

The Toyota Way: Respect for People and Continuous Improvement

That’s how I’ve seen Toyota distinguish between the two in their publications.

You’re right… you need all four pillars. One is the overarching management system, one is the production system.

Allow me to repeat a comment I made a few months ago on this blog regarding the “thought leader” in question. It may be helpful in putting the issue pertaining to the bully both into context (using a bit of humor) and to rest:

“RP has always been important in the history of progressive management because it is what enables CI. Without RP, CI falls flat or quickly dies, and you get Fake Lean/LAME. The two principles are connected [in real time].

The major distinguishing features between progressive management and traditional management is the use of the scientific method and the RP principle. To ignore RP is to not be fact-based; a nutter as it were.

I gave a presentation about RP in 2007 and was followed by the tosser Brit in question who, immediately upon taking the podium – the very first thing he did – was criticize my presentation as codswallop. Such brazen willy-waving!

I don’t know what motivates this type of narrow mindedness and willful desire to ignore history. Perhaps it does not serve one’s needs, or simply a perpetual ring-sting. Regardless, we have had to deal with nobbers, pillocks, and ruffians in the past will certainly have to do so in the future.

1920s British flow production pioneer Frank Woollard characterised the RP principle in his day as “Benefit for All,” and has this to say about it: “This principle of ‘benefit for all’ is not based on altruistic ideals – much as these are to be admired – but upon the hard facts of business efficiency.”

The brave people who have actually achieved flow in practice know this.

Our friend unfortunately possesses a low-grade understanding of the Lean management system. He does not understand it as a solution for information flow problems. If he did, the requirement for the RP principle would be self-evident.

For example, it took Woollard 2 years to achieve flow in the engine shop, but it took Ohno 5 years do the same. Could having poor people skills, as Ohno was well known to have (and Woollard not), contribute to that outcome? What our friend ignores, as most people do, is TIME.”

As far as I have understood, “Respect for People” in Lean means that management must acknowledge the fact that people who do the work are the ones who understand the work best – a) how it’s currently done, b) what are the challenges/what is causing waste and c) how to improve the way the work is done.

Management must empower, encourage and coach employees to plan & implement improvements. If there was a motto for RfP, it could be “Ask the team!”.

Kaizen workshops are powerful because they bring people who work as part of a specific value stream together face-to-face -> magic happens. Workshop participants analyze the current state (VSM), problems & root causes, future state (VSM), create A3s and an action plan/roadmap. Improvement actions are then incrementally implemented during the following weeks.

If an organization has “development managers” or “corporate development department” who mostly communicate only top-down a stream of powerpoint slide sets and guidelines (based on their own speculative analysis) to people telling them how to do their work, it’s likely that “respect for people” principle isn’t followed – no matter how civil, nice, respectful and professional people might otherwise be in that organization.

Jarkko: It is true that the people doing the work know the WORK best. They often do not know the Lean principles or simple industrial engineering principles like flow-process charts, multiple activity charts, time studies (for discovery of opportunities). It is my contention that respect for people also includes giving them Lean tools to use and training/education experiences in developing mutual respect among themselves. As many have discovered, for instance, the blocks to Lean in hospitals is not technical, it is sociological and systemic. That is what the people doing the work need to learn, how they can work more effectively together because they are all trained in a new language and thought pattern about the work itself, imho.

Paul: Great comment and I fully agree. I think managers need to be coaches and trainers who teach lean principles, thinking and tools to employees. Typically we have an experienced lean coach facilitating workshops and improvement “sprints”.

I love the break down of the seven components of Respect For The People. It kind of becomes a checklist to use and to check and adjust your RFP Level!

Respect for the People is the fertile soil that gives your Continuous Improvement program the nurturing environment it needs to develop strong roots.

Great share Mark! Thanks!

Thanks for the link to article and the split of Respect for People. I think it is a important part which often gets a bit too soft. I really like Bob’s discussion on it. Personally after different trainings (with some bullying style senseis also) in Japan I connect Respect for People to the 8 wastes. Individuals spend alot of time of their life working, probably more than with their friends and families. Respect is removing waste so you can do more value-added in line with the purpose of the organization. Respect is training, coaching, enabling and creating systems so that people themselves closest to the value-added can do that.

This can be done in a derogatory style but the pace would be much slower. That doesn’t mean that you should do it in a soft manner, sometimes I think that’s where the confusion starts and so some people instead rationalise that you can bully as long as you can get results. The direction should be clear and the process can be tough. So I would add to the breakdown of respect a dimension of focusing on value added and the purpose of the organization, e.g. mutual trust is built through delivering and getting waste removed so you get more purpose in your job, everyone has to take responsbility and workto remove waste, and we have to understand each other of what is value added and what is waste … etc

Joakim – thanks for your thoughts. I think we are in agreement that a bullying style is not acceptable, even if one gets results. Those results might just be short-term…