My friend Chad Walters has contributed guest posts to my blog (and has been a podcast guest), and I'm happy to return the favor with a guest post on his site: “Guest Post: A Clown Post About Bryce Harper and Warnings.”

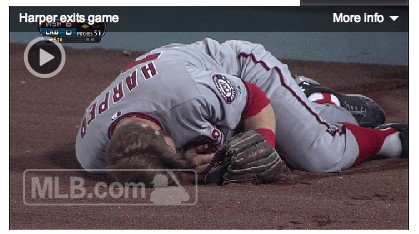

Since his “Lean Blitz” blog is sports-themed, I wrote a post about warning tracks (and how players like Bryce Harper, pictured below, often ignore them), the general ineffectiveness of warning signs in different workplaces (including healthcare), and how mistake proofing and better processes need to be the way we ensure safety and quality. Check out the post. I hope you enjoy it and that it's a bit thought-provoking.

The full text can be found below the photo and the video

A Clown Post About Bryce Harper and Warnings

By Mark Graban

Although he might call this a “clown post, bro,” I am writing about Washington Nationals outfielder Bryce Harper and how he plowed full speed and face-first into the outfield wall at Chavez Ravine on Monday night (article and video via Deadspin).

Running into the wall face first caused a nasty cut (requiring 11 stitches), a hurt shoulder, and a suspected concussion. Harper crumpled to the ground in slow motion and seemed to give his best “Hey, wha' happened?” reaction when the trainer ran out to him.

Harper is no longer a rookie, but you'd think he would know how to find the outfield wall… it's called a warning track. As Deadspin said, “It's called a warning track for a reason.” The warning was not heeded by Harper. Maybe he thought this was a rickety minor-league wall that he could run right through, as seen in this classic clip from the early 1990's:

Details About Warning Tracks

The now familiar warning track was first utilized in Old Yankee Stadium, where a running track probably just happened to be convenient for that purpose. The warning track was officially mandated by Major League Baseball in 1949 after earlier using sloped inclines to warn outfielders.

The standard warning track today is brown (or sometimes orange) dirt (or a polymer blend) that provides both a color contrast and tactile contrast from the outfield grass. As an outfielder speeds or lumbers toward the wall, peripheral vision and the feeling under foot tells the outfielder “warning: wall approaching.” The polymer blend also claims to give an audible “crunch” sound for the outfielder.

The international standards organization ASTM actually has a published standard for baseball warning tracks: “ASTM F2270 – 12 Standard Guide for Construction and Maintenance of Warning Track Areas on Athletic Fields” (how anal-retentive does that sound?).

It states, in part:

In order to provide for an effective warning track surface, the warning track must be constructed and maintained in such a manner so that the player can sense the change in texture from the regular playing surface and the warning track without having to look. This feature is very important in that the player is often visually focused on the ball during play and would not be looking at the ground as he/she is running toward the warning track. The warning track must also be constructed and maintained in such a manner that the warning track itself, or the surface transition, does not pose a hazard to the players.

Does not pose a hazard? That's not always the case, apparently. New York Yankee Mark Teixiera blamed their stadium's warning track for an injury to then-teammate Lance Berkman in 2010:

“That warning track around our stadium is very dangerous,” Mark Teixeira said Thursday of the synthetic surface. “It's hard, it's basically concrete with sand on top. It needs to be fixed.”

Berkman didn't disagree with Teixeira, but he wasn't as blunt. “It's slick, it's hard,” Berkman said. “I don't have much experience with it, but most warning tracks are not that way.”

The warning track is supposed to be about 10 to 15 feet wide (or three full running strides), but there's no exact standard for that, per MLB rules or the ASTM.

A Non-Warning Track Made of Turf

Earlier this year, the Texas Rangers and San Diego Padres played two exhibition games on a field crammed into the Alamodome's football footprint. The stadium featured an incredibly short-porch right field of just 285 feet (with a non-monster-like 16-foot wall), as shown here:

When I was there for one game, I noticed how the “warning track” around the field was really just brown artificial turf. This clearly violates the ASTM standard, as it couldn't possibly have a different texture than the outfield “grass.” I don't think this caused any injuries, but it was just two meaningless games (although some have criticized Harper for playing too aggressively with a 6-0 lead… just play it off the wall, bro).

The ASTM standard, by the way, says you CAN have a turf warning track IF it surrounds a “skinned” (or dirt) area, such as the infield for software. Not the case at the Alamodome.

Lean Lessons – Mistake Proofing Trumps Warning Signs

So what's the takeaway that's relevant to those using the Lean methodology? The lesson is that warning signs don't always work in any workplace. I've collected a number of signs on one of my blogs, “Be More Careful!”

There's one sports-related sign, one that I found sitting in the center field bleachers at Wrigley Field – if you wander up and sit behind/under the famous manually-operated scoreboard. Sitting there, if there were an exciting play (not likely, considering the Cubs), a fan would easily jump up (forgetting the sign) and bump their head.

I once saw a glass wall/window at a hospital that had a warning, as if the employees and visitors were birds – “Don't walk into me… please!” Could be helpful on outfield walls perhaps.

This warning sign on a piece of pharmacy automation warned workers against putting their hands inside the machine when it was running. A truly Lean environment (and your average non-Lean factory) would be sure to have equipment that could NOT be opened while running. We'd call this “mistake proofing” (or “poka yoke” in Japanese).

It's better to have a process where it's impossible to make a mistake rather than relying on people to be careful. We are more likely to have perfect processes than perfect people. The Toyota Production System produces better products because they build in quality rather than trying to inspect it in at the end of the line. They don't have more warning signs or more inspectors – they have better process. There's quite a history of this at Toyota, going back to the days before they made cars, even.

Warning Signs Don't Prevent Medical Errors or Other Fatal Mistakes – We're All Human

In the case of serious surgical errors, it's apparent how warning signs would probably not be effective. If they were, we could just post a bunch of signs everywhere, including one that says, “Warning! Don't operate on the wrong side of the patient's brain” – as errors like this occur all too often.

Hospitals don't post warning signs that say, “Caution: Don't give the babies the wrong medication” or “Warning! Don't mix up the laboratory specimens.” I'm glad they don't have signs like this because they wouldn't be effective.

Warning signs are pretty useless. ESPN even wrote that “warning tracks are useless.” At best, warning signs are a last resort – to be used only if you can't find any way to error proof the problem. Warning tracks seem to fit into that category. It might not be 100% effective, but it's better than not having a track.

Bryce Harper KNEW the wall was there (he can't be that dumb, bro). He just forgot in the moment. That's often how errors occur, whether it's a medical error or forgetting to set the flaps on a plane before takeoff or hitting a Boston overpass with your bus, even though there was a warning sign (a lesson in error proofing that had fallen into disrepair).

We're all exceptionally human. We make mistakes. I just don't know how you truly error proof against running into the outfield wall.

I guess a Lean countermeasure would be making sure the wall had enough padding (Harper hit a section of scoreboard in the Dodger Stadium wall). I'm sure there is an ASTM standard on the thickness and softness of wall padding? Maybe to be explored in a future blog post…

Let's be careful out there.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s build a culture of continuous improvement and psychological safety—together. If you're a leader aiming for lasting change (not just more projects), I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s talk.

Join me for a Lean Healthcare Accelerator Trip to Japan! Learn More