This article appeared back in March… March of 2013… as in this year: “Windsor Chrysler workers reduce waste to be world class.” I mean, good for them, but they are just now getting to this (even if the effort started in 2009 or so)… in the auto industry? Many hospitals were applying Lean thinking before then. Was that Chrysler plant expecting Toyota to just go away? I worked at a GM plant from 1995 to 1997 and the writing on the wall was clear that Lean / Toyota Production System was the winning formula.

This article appeared back in March… March of 2013… as in this year: “Windsor Chrysler workers reduce waste to be world class.” I mean, good for them, but they are just now getting to this (even if the effort started in 2009 or so)… in the auto industry? Many hospitals were applying Lean thinking before then. Was that Chrysler plant expecting Toyota to just go away? I worked at a GM plant from 1995 to 1997 and the writing on the wall was clear that Lean / Toyota Production System was the winning formula.

Thankfully, they have gotten results in the areas you'd expect:

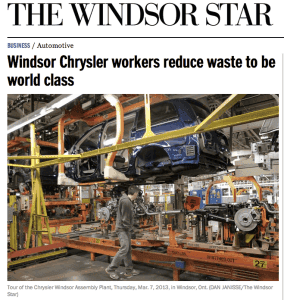

By eliminating waste, Windsor Assembly has achieved cost savings of $232 million since the inception of WCM [world class manufacturing], said Dan Omahen, plant manager. Workplace injuries have been reduced by 81 per cent, he added.

On the quality front, the number of minivans requiring warranty repairs has decreased by 69 per cent.

At least Chrysler / Fiat realizes it's about people:

At the heart of WCM is employee engagement, said Omahen. Since the implementation of WCM, employees have contributed 97,778 ideas for improvements and 77 per cent were implemented.

“There's several important pillars here, but the most important one we realize is the people.” Omahen said as he motioned towards a wall of the front office that displays the most outstanding cost-saving ideas by employees. “We want people to take ownership when it comes to driving change.”

Omahen has adopted the language of WCM, referring to employees' ideas as kaizens — the Japanese word for improvement. One kaizen, for example, came from an engineer whose project saved more than $59,000, he said.

In fact, more than 80 per cent of [plant manager] Omahen's time now is spent on the factory floor talking to employees.

That's the leadership style I saw from the second GM plant manager I worked under (he was one of the first GM at the NUMMI joint venture plant with Toyota). Being at the “gemba” (the workplace) and working together on improvement, not just dictating answers to people.

From the Chrysler article:

“Before WCM, we were dictated to,” said Mark Dana, an hourly worker who leads a team of about 10 employees in the plant's tire assembly area. “Now workers have a say, and as a team, we work to solve problems together.”

That's the Lean / TPS leadership style. Congrats to Chrysler for finally getting on board…

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

Mark,

This isn’t *lean*! It’s different! It’s “World Class Manufacturing”!

It’s not Japanese, it’s Italian! I came from Fiat!

-Andy

Whatever way you spin it, those are fantastic results! Well done!

Well, I was certainly stunned by that article. I took the top management team from my former company to the Chrysler assembly plant in Michigan (it was so long ago, 1989 or 1990 i’ve forgotten the name of the suburb of Detroit it was in, a former Redstone missile plant, I think) to see Lean (WCM) in action. All the stuff described in the above article was being done there. So, I guess it got lost or something. Or people don’t talk together. Or, more likely, management gets distracted and forgets that if they are Lean, nobody can beat them so that is Job One!!

I’m sitting here shaking my head at the ineffectiveness of Chrysler management and many managements in general who don’t ‘get it’—it is ALL about people and processes, period. WCM was the name in the US before Lean was adopted. The more things change, the more they stay the same.

I’m blown away. Maybe Real Change is impossible over the long term because of Management’s short term thinking. I know that P&G ditched an incredible company wide program called “Deliberate Change” that was, literally, saving them hundreds of millions when management changed and the group responsible was dispersed to the individual plants where they were swallowed up the the day-to-day and disappeared. Just crazy.

Paul

Hi Mark

This is Chryslers latest round at doing this, the first time was when Lee Iacocca headed the company and he never called it Lean, he just considered it the best way to do business. He involved people at every level in everything, workers, dealer staff, and production support staff helped design cars so they could be built right, quickly, and in a fashion that allowed service. It lasted through their next two CEOs, who had always been part of Lee’s team. After Yves Landry’s death Chrysler went back to its old ways, and Daimler didn’t do anything to change it so it just kept going downhill.

When Fiat took them over they began to reapply it, but it takes time to win back the support of your work force, after all most remember being held to blame for every Chrysler problem in the post Landry era. Fiat leadership focussed first on winning back the support of the blue collar workers, and their production support staff, all of whom suffered during the dark era that ended with the Fiat takeover. But we shouldn’t forget who actually taught Fiat what to do; it was the Ford Motor Company, and a select group of ex-Chrysler managers of the Iacocca era that went to Fiat while they were rebuilding themselves.

We shouldn’t forget that many of the ideas Toyota put into practise actually originate in the USA, and most in fact were the ideas of Henry Ford. It is unfortunate that it sometimes takes foreign competition to teach us to actually implement our own ideas. Isn’t a one time concept that to get Lean to really take hold requires a crisis to exist to help drive the change.

Thanks, Robert. You’re right about Ford, etc. Great summary and comment. However, Ford never solved the variety problem. “Give them any color they want as long as it is black” is supposedly said by Ford. It took Shigeo Shingo 15 years to fully solve that problem through quick changeover “technology”. I’ve seen 15 ton press dies changed in 4 minutes that used to take half a day or more. I, personally, think that is one of the great contributions of Toyota to the “Lean” portfolio of ‘radical’ ideas. But, Ford’s were the most encompassing except the ‘respect for people’, which he didn’t have. That’s one the Japanese had as did Iacocca. Thanks for enlightening me on where and why Lean went. When troglodyte management takes over. there’s suffering everywhere.

Kudos to the Windsor plant. Lean is a process that always sounds easy on paper. Many companies must goes through what I call lip service (Lean Illusion Process). You know read the book, pretty the shop say all the cool words, mudu, poka yoke, value stream…. But never change the culture or the accounting. After years of the illusion its typically the finance department that identifies the cloth-less king.

Its normally at this point similar to an alcoholic hitting rock bottom does true change begin.

I was wondering if Chrysler would jump into Six Sigma. I am glad to see that they are getting some good results from it. I noticed that they were starting to jump back from the depression.

I don’t think Six Sigma was mentioned at all. Toyota doesn’t do formal Six Sigma with belts, etc.

Lean and Six Sigma are not the same thing.

David: GREAT acronym that I had not seen before. LIP service, indeed. That’s what MOST US manufacturing folks go through, for sure. The several times I’ve tried to coach (as a consultant) an organization to do real lean as against faux lean, I’ve been slowly stonewalled and then “fired”. Not a great outcome but I’ve reached the place in life where I will not work with an organization unless the top person, or persons, understand, deeply, what they are undertaking. Waste of my precious life’s time.

Paul

[…] When we consistently (ahem, faithfully) pursue these strategies… and when leaders start leading in a new way, “Don’t Stop Believin’” that you can create a sustainable Lean culture — even in a factory in “South Detroit” (ahem, Windsor). […]