I've been fortunate to have the chance to visit an Autoliv factory in Utah – a great Lean company that makes air bags and protective devices for cars and passengers. I was really impressed with Autoliv, as were the healthcare leaders from across North America who visited as part of the Healthcare Value Network efforts. Like healthcare, the work done by Autoliv is a matter of “life or death” with a very strong mission and sense of purpose. The HVN visitors were very impressed with the quality culture and the prompt management support that's made available when a problem occurs in a production cell.

I've been fortunate to have the chance to visit an Autoliv factory in Utah – a great Lean company that makes air bags and protective devices for cars and passengers. I was really impressed with Autoliv, as were the healthcare leaders from across North America who visited as part of the Healthcare Value Network efforts. Like healthcare, the work done by Autoliv is a matter of “life or death” with a very strong mission and sense of purpose. The HVN visitors were very impressed with the quality culture and the prompt management support that's made available when a problem occurs in a production cell.

At the AME Spring Conference in San Antonio, I saw a presentation by Thomas Hartman, a Senior Director at Autoliv: “17 Years on Lessons Learned: Building and Sustaining a Lean Culture.”

I'm “live blogging” the presentation in this post and will update it as the talk goes. Unless in italics the comments are quotes or paraphrases from Thomas.

What's your most effective offensive strategy against your competition? Your people! Increasing your rate of improvement in every facet of your organization – builds upon your investment in people. If you're not improving faster than your competition, you're in trouble!

Their Lean journey started in 1995. Their “lean healthcare” journey with their own primary care clinics started in 2008 (10,000 employees and dependents). Why? Because we can – and it works.

How do you increase your rate of improvement? “Leverage the total capability of your team.” All of our people have hidden talents (art, music, carpentry, etc.) — draw those out and you get the total capability of your people – not just “I only want you to do what I told you to do —- you'll get just that or less.” You want an environment where people are encouraged to show their capabilities and are rewarded for it.

Engaging people, enabling them to add value to a great degree. Kaizen, PDCA, Deming, Six Sigma, Lean, TWI — all accomplishing the same thing.

How do you raise the skill and ability of your team?

- Build a “trusty team” that will ADHERE to standards – standard work (understands your expectations very clearly, who, what, when and WHY)

- Empower your team to IMPROVE those standards (because they can predict where the business is going)

What's good for today is not good for tomorrow. The goal is to improve continuously.

They asked a team (production cell) what they needed to do to be successful. “Everything at Autoliv is teamwork… we reward as teams.” Things the team came up with include:

- We will always follow our standards to ensure safety, quality, customer satisfaction.

- We will always stop and fix IMMEDIATELY any problems – get to root cause and share solution

- Strive to continuously improve by always listening to new ideas and implementing our improvements

How do you build a “trusty team?” — servant leadership is key.

- Management and team must understand “True North” and always move in that direction – where are you going and why? We teach this EVERY day.

- Get targeted results through effort of the team

- Pull the ability from inside each team member

- ALWAYS create an environment conducive to the continuous improvement process

- Use the workplace as a laboratory to teach the team how to improve

RESPECT what the team gives you.

When you see something abnormal, you ask how you can help rather than blaming people and yelling. The old style is to tell them what to do rather than putting them into a position to figure it out through coaching and support. Everything you do should raise the capability of the team and their thinking.

We had some “butt kickers,” people who really didn't want to lead, and those who engaged people.

The butt kickers left because this was all too “namby pamby.” Those who didn't want to lead couldn't handle it. Those who liked engaging people are the ones we have leading now.

You need CONTROLLED experiments (especially being in the safety business).

AMT = Autonomous Manufacturing Team

Keys for improvement:

- Best is the worst enemy of better

- Try and fail then try again – a great method for pursuing perfection

- Failure is a temporary condition that occurs naturally and frequently on the road to success

The only failure is stopping trying to achieve better. You never develop perfection. The only thing you have that's perfect is your attitude, your perseverance and your ability to improve.

If you're not improving, THAT is failure. But that's only temporary.

Suggestion programs aren't successful – why?

- Management doesn't follow up (“ideas go to the box filled with gum wrappers.”)

- Workers aren't part of the improvement

- “That was a dumb idea!”

If you expect good suggestions, you treat them with respect. That idea is part of the person they gave to you.

The goal is finding the systemic root cause and never repeat the problem. Public hangings don't improve morale – don't burn anyone at the stake.

Respect for the individual (EVERY individual) is a foundational element of the Culture of Continuous improvement.

Team goals motivate individuals (through peer pressure) to not disappoint their team.

“As the team's capability slowly increases, team suggestions become more frequent and more valuable.”

Our leaders must be TEACHERS or they can't effectively lead in a culture of continuous improvement. You cannot foster what you don't understand.

We have to teach people the WHY, in additional to the who, what, when, and how. Then, they can improve when we're not there. Continually raising the skills of our people.

For a sustainable culture of Lean, you must promote from inside. You already know they fit with your culture. Should RARELY hire from outside of its cultural base. The higher up a person, the higher risk of cultural mismatch. Senior leaders MUST be fostering this whole process.

Toyota sent a person to work with them from 1998-2002 because “we had a good attitude” (but were really messed up). The Toyota guy was teaching them every day. “He lived with us every day but worked for Toyota.”

Process for managing improvement:

- Set the target

- Let the team work independently with minimal supervision

- Only support when necessary

- Help the team reach the target and succeed through “invisible support.”

- Working with the team, evaluate the method and results for potential improvements

Give them enough rope to pull the wagon but not enough to wrap around their necks and hang themselves.

It's amazing that the AME conference has been so focused on culture, thinking, and leadership, including this talk.

They had 100,000 kaizens in one year (real number – “no joke.”). A plant of 1100 people. Next year did 43,000 “team workshops” (more complicated improvements) — shifted a bit from Kaizen approach.

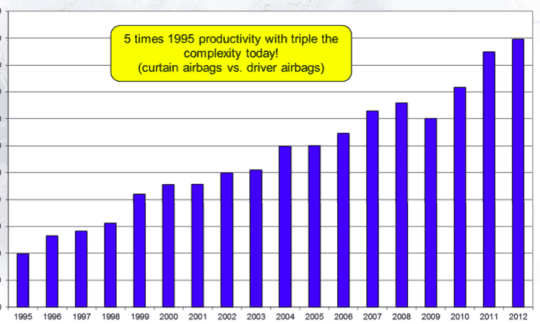

Their largest plant has FIVE times the productivity of 1995 with triple the product complexity (larger and harder to build). No diminishing returns on improvement (LINEAR ongoing improvement). Modules produced per total head.

2009 was market downturn.

“Our leaders inspire, they don't intimidate.”

“Improving is not optional, it's a requirement.”

Improvement is not rocket science. SO WHY DON'T PEOPLE DO IT?

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

Great post Mark. It is wonderful to see what Thomas Hartman and his team have done at Auotliv. Keep up the great work (you too Mark).

[…] yesterday’s “live blog” post about the Autoliv talk, I also wrote this post as Art Byrne talked, but held it for today. He is author of the book The […]

[…] this episode, Alan talks about how they got started with Lean, what they learned from Autoliv and the Shingo Prize assessment process (being the first healthcare organization to do that). He […]