While Lean is not primarily a cost-cutting methodology (or, we could say it's not focused ONLY on costs), cost reduction is a common end result of improving safety, quality, flow, and other factors.

Since 60 to 70% of a hospital's costs are labor, typically, it's tempting for hospitals to slash headcount when things get tight financially. This is a common healthcare response and Lean provides a great alternative to morale-damaging layoffs.

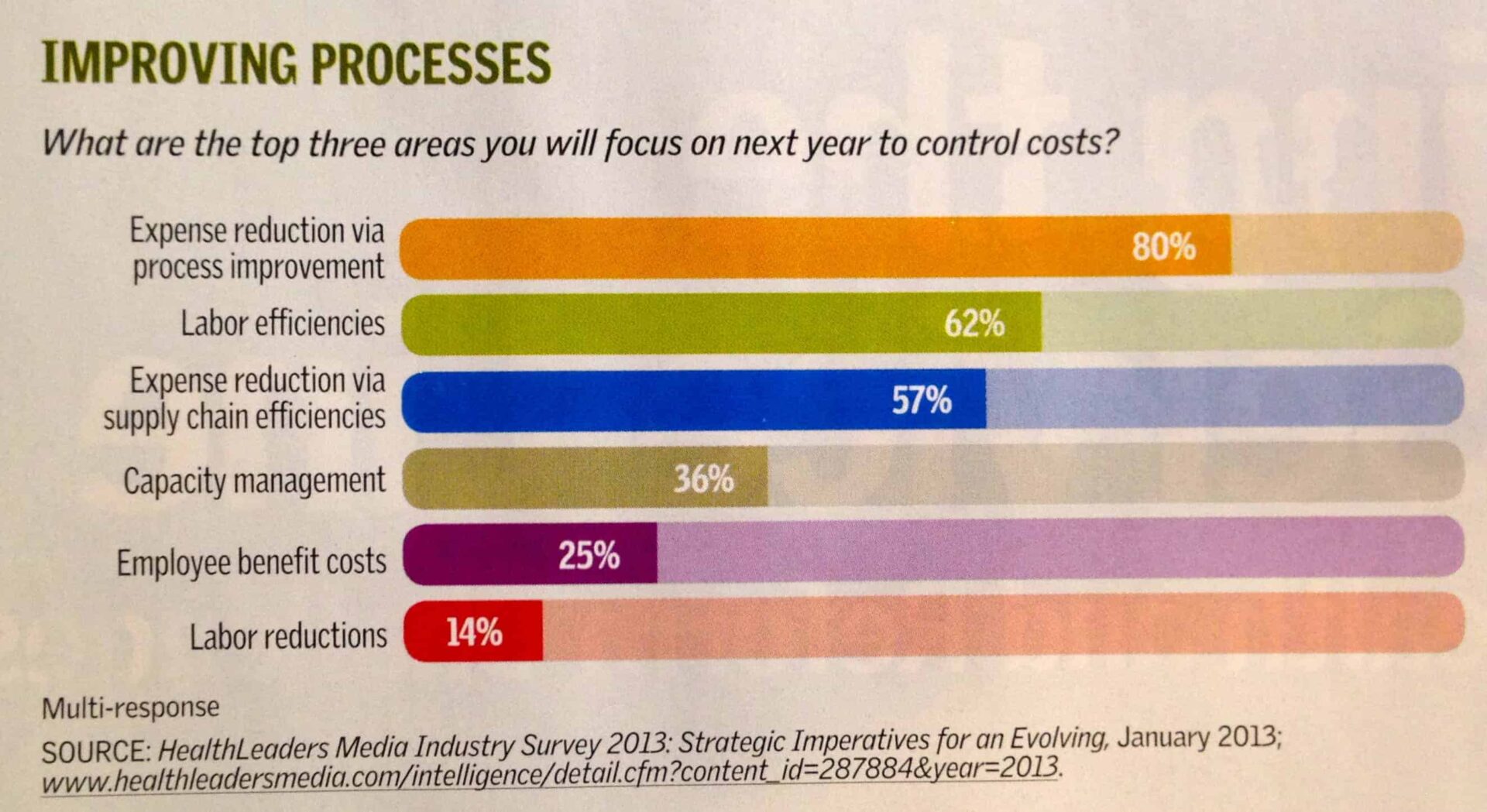

This infographic / chart in the most recent edition of Health Leaders caught my eye:

I was happily surprised to see that “process improvement” was at the top of the list while “labor reductions” was at the bottom.

Ironically, I was recently told of a health system that eliminated their Lean/P.I. department in the name of short-term cost-cutting. Ugh. See here.

This recent Becker's Hospital Review piece, “9 Ingenious Ways to Cut Costs at Your Hospital,” called out many cost-cutting tricks but didn't mention Lean and process improvement, unfortunately.

Copying things other hospitals did, like energy savings and putting coffee pots on timers will have a trivial return compared to teaching methods like Lean and Kaizen. It's like the difference between giving a person a fish (copying this improvement) versus teaching them how to fish (how to identify and implement improvements of their own).

Is your organization doing things to cut costs in these challenging times that are destructive or constructive?

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

That is definitely very good news. Although resources are still borderline thin, there does seem to be a lot more Process Improvement focus going on in our hospital as well. Our Performance Improvement team has just started a Bronze Lean training for employees similar to the one offered by SME/ASQ/Shingo. A sense of urgency seems to be rising. Let’s keep it going!