Last year, the Institute of Medicine released its latest report titled, “Best Care at Lower Cost: The Path to Continuously Learning Health Care in America.” The report endorsed Lean as one strategy for improving the problems in our health care systems around the world.

From the full report (available as a free PDF download, with registration required), based on the Steven Spear “rules in use”:

One notable strategy for improvement is the Toyota production system (Bohmer, 2010; Kenney, 2011). Under this system and related strategies, work is viewed as a series of ongoing experiments that immediately reveal problems. First, each worker's tasks are broken down into highly regimented sequences of steps. These steps make clear when workers are deviating from specifications and help both workers and their supervisors monitor adherence to the work process. Second, connections and communications among workers and between workers and outside suppliers and customers are standardized. Each communication unambiguously states the expected result of the request, the person or people responsible, and the time within which the request will be met. The third step of Toyota's production system is to create simple, defined workflows for the products, services, and help requests that make up the company's production lines. These workflows deliberately and systematically link sets of tasks and communications together, thereby reducing ambiguities. When ambiguities do arise, the fourth and final step of Toyota's production system is to teach workers how to address them, requiring that changes to workflows be in accordance with the scientific method, guided by a teacher, and made at the lowest possible level of the organization. To meet this requirement, Toyota trains its workers to frame problems and to formulate and test solutions. In this way, the organization fosters a learning environment in which workers at all levels are invested in identifying the root cause of problems and developing practical, implementable solutions (Spear and Bowen, 1999).

It's great that they shared examples of Lean success (including those from ThedaCare, Virginia Mason, Denver Health), but I fear that the Spear / TPS “rules in use” framework seems a bit too mechanistic for healthcare environments… the idea of “highly regimented sequences of steps” might be more readily applicable to highly repetitive car assembly work than to healthcare. I think there are great benefits to being more standardized or “more highly regimented,” but we have to be careful about trying to take that to an extreme.

I do think the idea of rigorous problem solving – and training everybody to participate in this – is a key strategy, aka “Kaizen.”

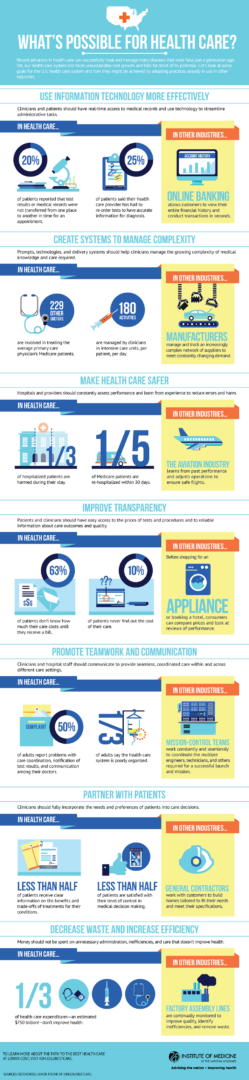

They also created this infographic (click for a larger view):

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

It is really great to learn that the world is gradually moving towards a far more efficient and practical healthcare system. While it is too early to conclude that lean healthcare indeed is the ultimate answer to all health care problems in this world, we can at least be certain that we will be able to frame problems, and to formulate and test solutions. In this way, we will also be able to foster a learning environment within the health care systems around the world in which health care workers at all levels will be invested in identifying the root cause of problems and developing practical & implementable solutions.

Thanks for this timely article that is encouraging us to think “outside of the box”.