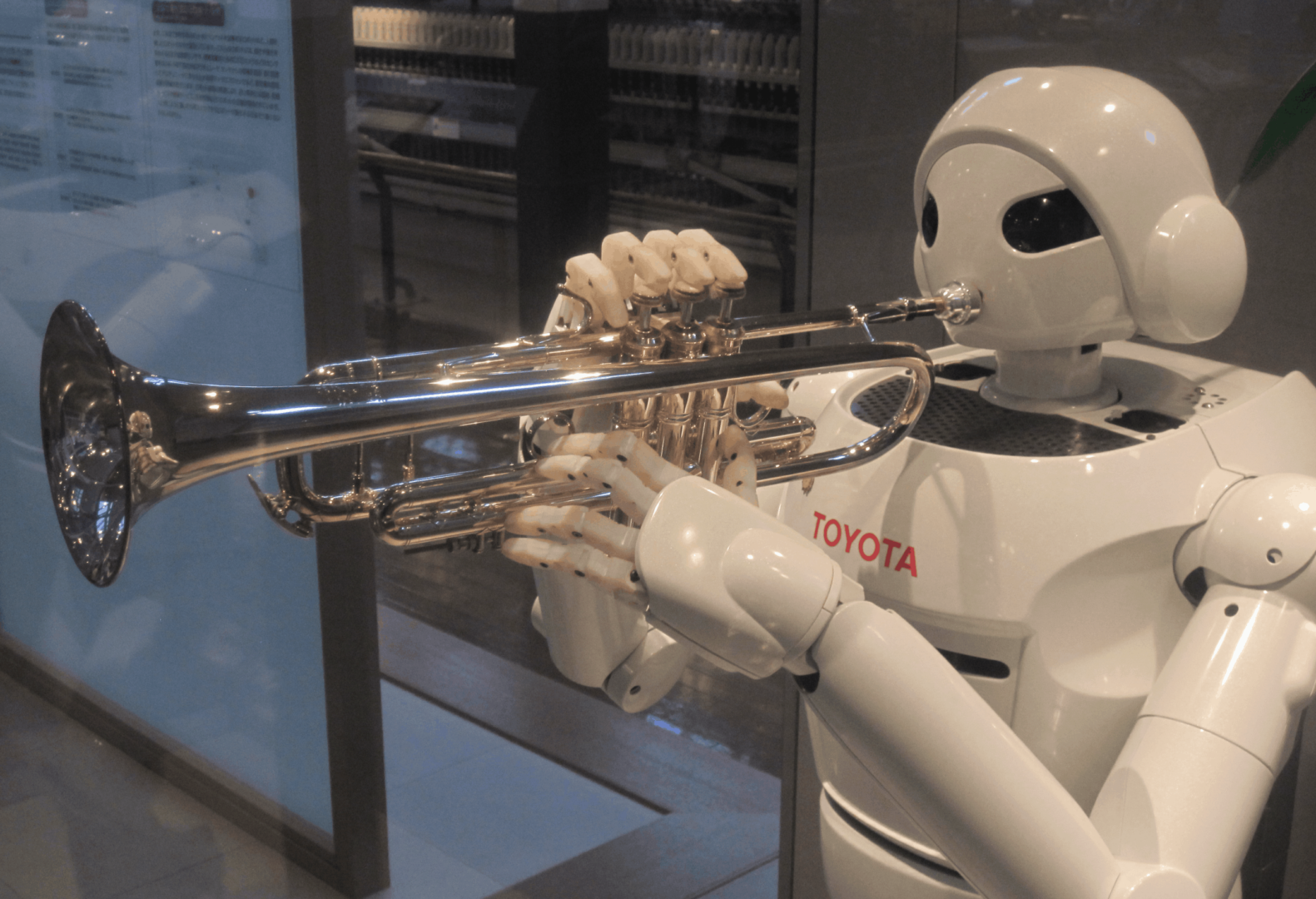

I know many of you aren't into the whole Twitter thing, but I'm using my account (@MarkGraban) to share some photos and small batches of ideas that I come across during my trip to Japan. I'll also share them here (but keep in mind you can read Twitter without having an account there, even). That's a Toyota “partner robot” pictured above.

2023 Update – I'm going to convert these Tweets into native photos and text.

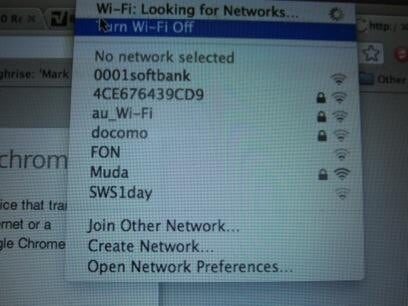

Lean thinkers will appreciate one of the wi-fi networks visible to me here in Japan — Named “Muda”

A video at the Toyota Museum gives credit to Womack, et al and their “Machine” book for spreading the word about TPS.

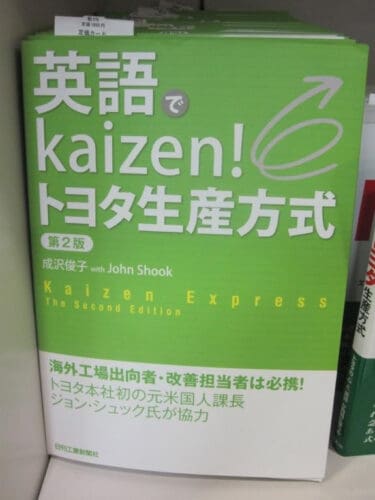

John Shook's book “Kaizen Express” (in Japanese & English both) was on sale in the Toyota Museum shop.

Other Thoughts I Tweeted

When a Japanese company hits hard times, the first action is the big boss taking a 40% pay cut. Then Directors, etc. do the same. The LAST step is to cut the pay of workers.

When recovery comes, front-line workers get their pay restored first, then the big boss is restored last. That's the polar opposite of US companies (lay off workers 1st).

From the Toyota visitor center: An animatronic Andon Cord Pull. It demonstrates flagging problems so help can arrive

I'm very surprised that Japan doesn't have the “Look Right” or “Look Left” curb markings like London does. I need to be careful!

It's still true that Japanese public company CEOs can only earn 20x a frontline worker (this is an unwritten rule). Small companies 10x ratio.

Me at the Toyota City visitor center. They really emphasize TPS in their exhibits, with detailed explanations. Click to zoom in and read.

Even in Toyota City, displays (and the faces you see) emphasize that this is a very global company.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

Mark, the reason there are no look left / right, is that as you’ll see if you get up to Shibumi (sp?) in Tokyo, people do not ever step out in to the road on red………….the road can be clear for 3 miles and they wait for the signal…………that was our experience. I particularly like the lines for getting on / off the train though.

How was France

Andrew

Ha, great point. You’re right there is very little jaywalking, if any, in Nagoya. Curious to see in Tokyo next.

I’ll email you our vacation.

Also follow Gert Linthout, who is on the trip:

https://twitter.com/GertLinthout

http://livinglean.blog.com/2012/11/13/iwata-city-hospital-inspiring-people-by-5s/