Mark's note: While I am busy in “moving land” this week, Christina Kach was kind enough to write a review of a book that was sent to me – Adventures in Leanland by Russell Watkins (a free copy was provided for review). The book was published through Lulu and you can also buy it there. Russell Watkins is a director of Sempai Consultancy Services, a business formed to assist organisations that are serious about improving the short and long-term performance of their business.

Review: Adventures in Leanland

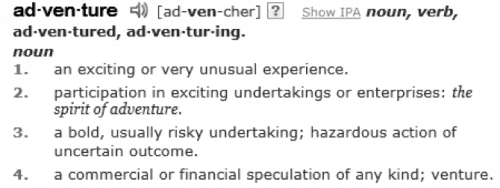

Dictionary.com has 4 definitions listed for “Adventure”

According to these definitions – I'm going on adventures at work every day! In his book “Adventures in Leanland” author Russell Watkins captures such adventures to share with the Lean community. Below, I review this new Lean work.

What is the key message?

Value! Value! Value! The key point Watkins wants to leave with us is the importance of value in all its forms. Watkins reviews the impact of waiting until the end of a process for inspections, laments that having “no time” or “no space” available is rarely accurate, and we are ineffectively using our most valuable resources – the minds of the employees. In a unique perspective, the author addresses society beliefs that we live in a world of plenty, of infinite resources and scrap doesn't matter as there is more available. Twenty-first century society needs to learn to value our belongings. One way to addresses this value misconception in Gemba is to move scrap bins out of the shameful shadows and put them on display with the purpose of bringing awareness to scrap and its impacts to the business.

The most eye-opening reflection was the awareness the author brought to the greater world of Lean. Each country and company is dealing with a current set of struggles and will have new ones in the future. It is easy to be caught up in our own jobs and forget about other nations, industries, and the overall global perspective.

How does it contribute to the Lean knowledge base?

Watkins injects the book from start to finish with reminders of basic Lean principles. He looks at classic topics such as: Lean isn't easy, we have to continuously teach Lean, and it isn't about the failure of people but the failure of processes. The reader is urged to recognize the harsh truth that we are accepting weak businesses practices as good enough for our customers. In reality, what we are doing now is not enough to drive future successes. Watkins backs up this reasoning with some examples of current habits which need to be broken. Included in this argument is failing to specify what is normal so issues are caught before they are a defect, reworking later versus stopping defects from occurring or fixing as you go, and seeing 5S/WPO as a tool instead of a robust process to identify potential defects. Readers are encouraged to get down from high level perches that don't allow the granularity necessary to see the fine details influencing Gemba missteps. We need to stop hiding problems and begin nurturing a culture of seeking out problems, bringing them to the surface and solving them.

What are the highlights?

Lean practitioners will find themselves frequently in agreement and ruminating with Watkins' insights. For example, Chapter 2's lament about the “I don't have time for this” kiss of death to the hopes and dreams of Lean initiatives will be a familiar experience.

Watkins successfully transports us away from our cubicles to new environments, showing again that Lean exists everywhere. He challenges the clichéd “ignorance is bliss” mindset by reminding us that improvements for the customer cannot take place if we are not transparent with our people about business struggles and opportunities. Otherwise, how will our people on the front lines understand the issues and feel motivated towards change?

Just as we Lean practitioners start smugly turning the pages in agreement with the management issues that slow Lean implementation, Watkins reminds us we are not off the hook. As Lean educators we can be a part of the issue by being too concerned with giving answers and advice, rather than spending the time to listen, teach and ask the right questions.

One of my personal book highlights is Watkins' request for us to move past the fancy posters and groomed tour isles, and get to Gemba where the work is actually done. His point being: don't get complacent living in the past of what has already been completed. Lean is a journey, continue moving forward. I was also thrilled that one key message addressed throughout is also one of my personal Lean viewpoints: Problems are opportunities for improvement.

Also, I dare you not to drool at the fable of the “perfect” Lean factory. Of course, there is no such thing as perfect, and we are always working to improve, but it is nice to daydream.

What are the weaknesses? What's missing?

Well, as I just mentioned, nothing is perfect. Chapter 1 kicks off with a dry opening that didn't exactly hook my attention. While I enjoyed the adventures portrayed in the book, it took too long for those stories to appear (not until Chapter 5). For a book on Lean, I found the choppy thoughts and general lack of flow in the ideas and topics surprising. This book is not for Lean beginners. Terminology is not explained, and acronyms such as PPE and FIFO are not spelled out. That being said, I'm not exactly clear on whom the target audience is for the book. It flips back and forth between tales and voices of a Lean practitioner, management, engineers, and front line workers.

Watkins effectively blends talking to his audience directly, voicing opinions, providing examples, and telling stories to chronicle his Lean journey. There is even a bit of role playing utilized to guide home some key points. The author shares stories of his past blunders to remind us that we are only human. No one has all the Lean knowledge; we are all students of Lean. He clearly articulates his hopes that after this book is finished, we remember the importance of attention to detail, focus, and personal responsibility on our quest for business success. “Observe where it is failing and ask ‘can we do something about it?'” Chances are we can. And that can make for some very entertaining Adventures in Leanland.

Christina invites you to connect with her via Twitter (@ChristinaKach) and her blog for young professionals – “Catch Careers.”

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

![When Was the Last Time a Leader Around You Admitted They Were Wrong? [Poll]](https://www.leanblog.org/wp-content/uploads/2025/07/Lean-Blog-Post-Cover-Image-2025-07-01T212509.843-100x75.jpg)

[…] About Russell Watkins: Russell (@LeanSempai) is a director of Sempai Consultancy Services, a business formed to assist organisations that are serious about improving the short and long-term performance of their business. He has held various operations, materials and lean manufacturing positions within the automotive, aerospace and construction industries. He first experienced the harsh training of Toyota Japanese engineers in the 1990s, and his work since has taken him to businesses – shopfloors and boardrooms – throughout the UK, Europe, the US, China, India, Japan and South America. He is the author of the book Adventures in Leanland, reviewed here by fellow guest blogger Christina Kach. […]