Mark's note: Today's guest post by Bart Sellers is a timely contribution to follow up to yesterday's post about the ThedaCare Business Performance System and the journal article about that great work. Bart has been a frequent commenter here on the blog and I've enjoyed working with him through the Society for Health Systems (come join both of us at the upcoming SHS conference where we are both presenting on Kaizen).

Organizations that are trying to engage staff members in Kaizen (continuous improvement) efforts often ask questions about how many ideas they should be getting from each employee and how to motivate or inspire more Kaizen.

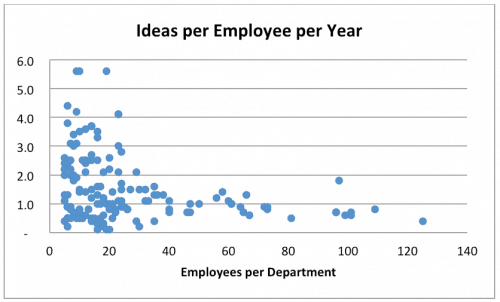

I recently shared some data with Mark Graban about the participation rate of employees in kaizen (“ideas” for some of us) based on department size for a group of hospitals that have recently implemented an idea system. See the chart below:

For smaller departments of less than 40 employees, there is wide variation in participation rates. In some of these smaller departments, employees average over five ideas per year while others are barely getting any participation.

In contrast, larger departments with more than 40 employees are almost uniformly unsuccessful in generating participation rates of more than one idea per employee per year. The one exception is a food services department with four full-time supervisors plus the manager.

These larger departments invariably have a list of good ideas waiting for either a preliminary evaluation or to be actively worked on. Managers for these departments report the bottleneck is that they and their employees don't have enough time to move ideas along. So, while the mechanics of the idea system are in place, and working extremely well, in a few instances, there are obvious shortcomings that are limiting participation in larger units.

Perhaps there are some lessons to be learned from a local auto parts manufacturer that adopted a Toyota type of organizational structure. Employees in this plant average several dozen implemented Kaizens, or small improvements, per employee per year. The plant is organized with a team lead for every five to six operators. The team lead is a production worker, but has two hours a day to work on staff development, trouble-shooting, and maintaining and improving performance. Each week, the plant is shut down for approximately 30 minutes on each shift for the operators to work on kaizen.

In addition to coaching from the team leads, there are also several employees on each shift that work in a small fabrication shop to support the front-line employees in implementing ideas. This type of support structure was a radical change from the flat organizational structure that was in place before and may even seem to be extravagant to some outsiders. But, this organization achieves substantial year-over-year quality and productivity improvement and continues to grow while all of its domestic competitors have moved off-shore.

Hospitals can't shut down for 30 minutes at a time, but the need to provide time and resources to support improvement is real and may require a dramatic change in management systems. Some hospitals have responded to this challenge, at least in part, by blocking out substantial portions of the workday or week for managers to engage in improvement. Kim Barnas, a senior leader at ThedaCare, has been leading such a change over the last two to three years and describes it in an article recently published in the Joint Commission Journal on Quality and Patient Safety (as Mark blogged about on Tuesday). Perhaps it is time for those organizations that have hit the wall on continuous improvement to re-examine their management systems to see if such dramatic changes are needed.

About the Author: Bart Sellers has worked as a process engineer in the aircraft and healthcare industries and over the last five years has focused on implementing Lean in healthcare. He is currently the editor of the Society for Health Systems newsletter.

Please scroll down (or click) to post a comment. Connect with me on LinkedIn.

Let’s work together to build a culture of continuous improvement and psychological safety. If you're a leader looking to create lasting change—not just projects—I help organizations:

- Engage people at all levels in sustainable improvement

- Shift from fear of mistakes to learning from them

- Apply Lean thinking in practical, people-centered ways

Interested in coaching or a keynote talk? Let’s start a conversation.

To flip this around a little, I’d suggest an even better metric to measure would be how many ideas you’re getting from your entire ecosystem. This should include staff, customers and all the other stakeholders you have in your world.

Technology makes it much easier to engage a much wider audience, it’s crucial to tap into it as often as possible.

[…] Perf[..] (RT @MarkGraban: New Post: Guest Post: Is your management system the constraint…Via http://www.leanblog.org Share this:TwitterFacebookLinkedInLike this:LikeBe the first to like this post. By Michel Baudin […]